Efficient insulator sweeping device

A technology for cleaning devices and insulators, applied to cleaning methods and tools, cleaning methods using tools, overhead line/cable equipment, etc., can solve problems such as heavy workload, low work efficiency, dangerous working environment, etc., and achieve high work efficiency , simple structure, flexible movement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but this does not constitute any limitation to the present invention.

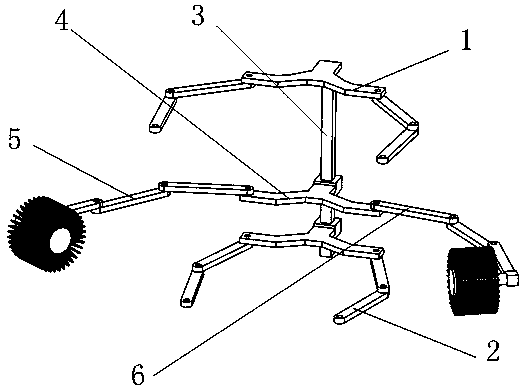

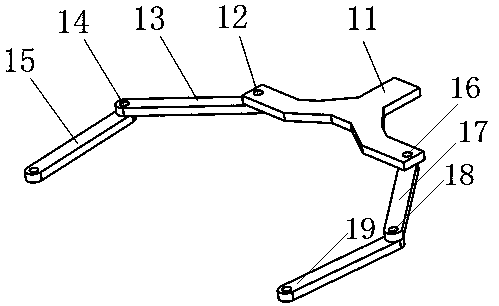

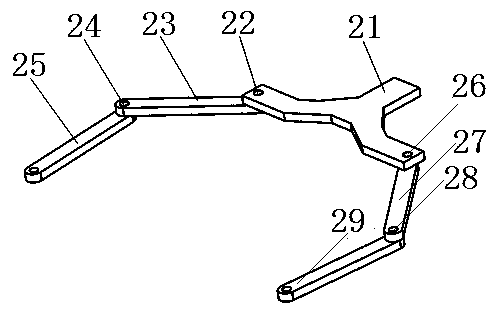

[0016] figure 1 It is a schematic diagram of the overall structure of the present invention, such as figure 1 As shown, a high-efficiency cleaning device for insulators is characterized in that it includes an upper jaw 1, a lower jaw 2, a moving frame 3, a cleaning connector 4, and a left cleaning part 5 and a right cleaning part 6 for cleaning insulators. The moving frame 3 is sequentially provided with an upper jaw 1, a cleaning connector 4 and a lower jaw 2 from top to bottom, and the left cleaning part 5 and the right cleaning part 6 are arranged on the left and right sides of the cleaning connector 4, respectively. The lower jaw 2 realizes the relative movement between the lower jaw 2 and the upper jaw 1 through the moving pair of the moving frame 3; the left cleaning part 5 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com