Corn threshing device

A corn threshing and threshing roller technology, applied in the field of agricultural machinery, can solve the problems of complex disassembly, inconvenient internal cleaning, unfavorable production efficiency, etc., to achieve the effects of ensuring efficiency, convenient moving and placement, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

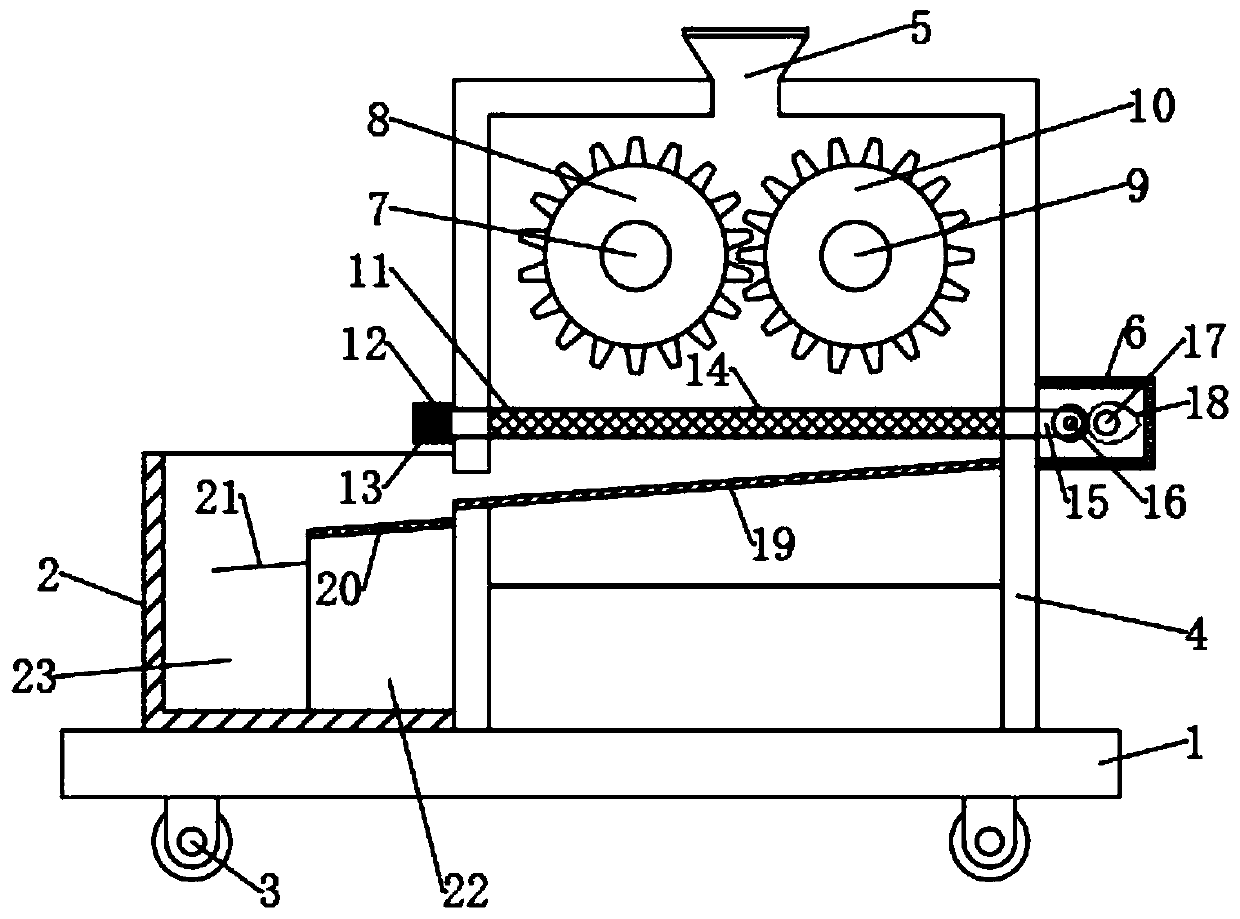

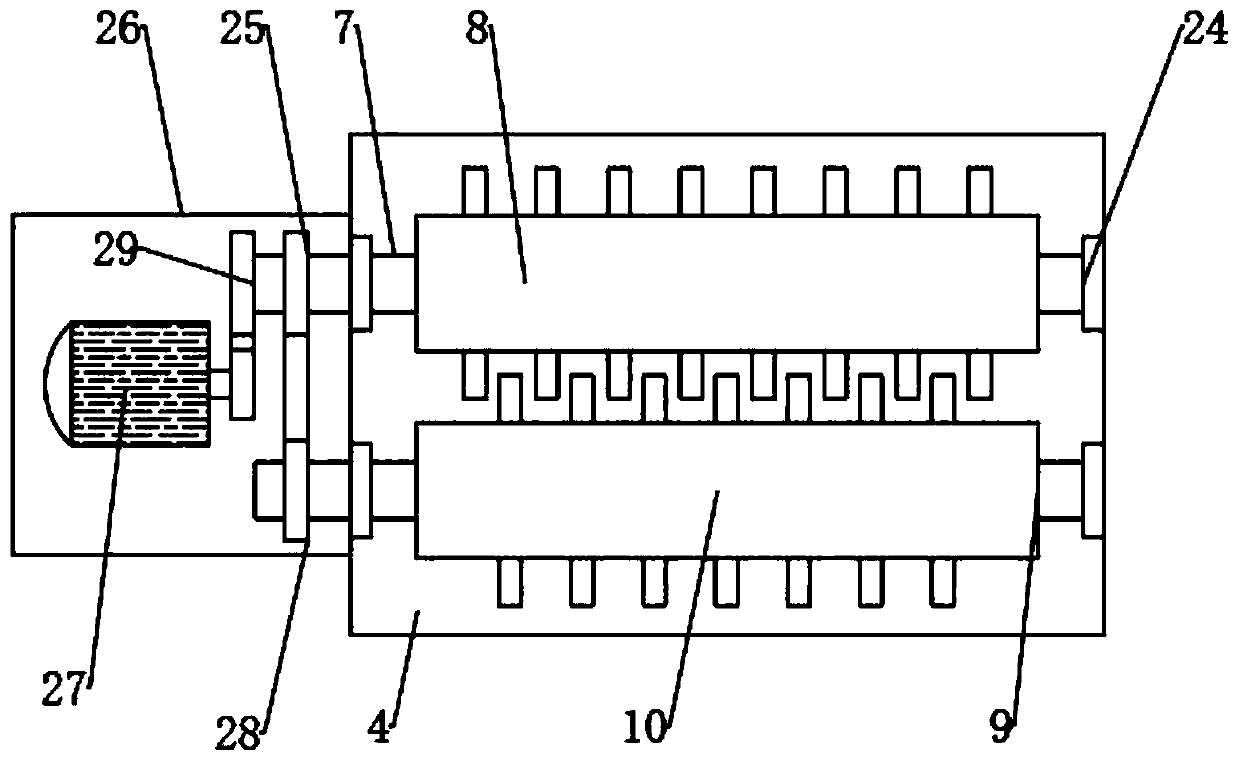

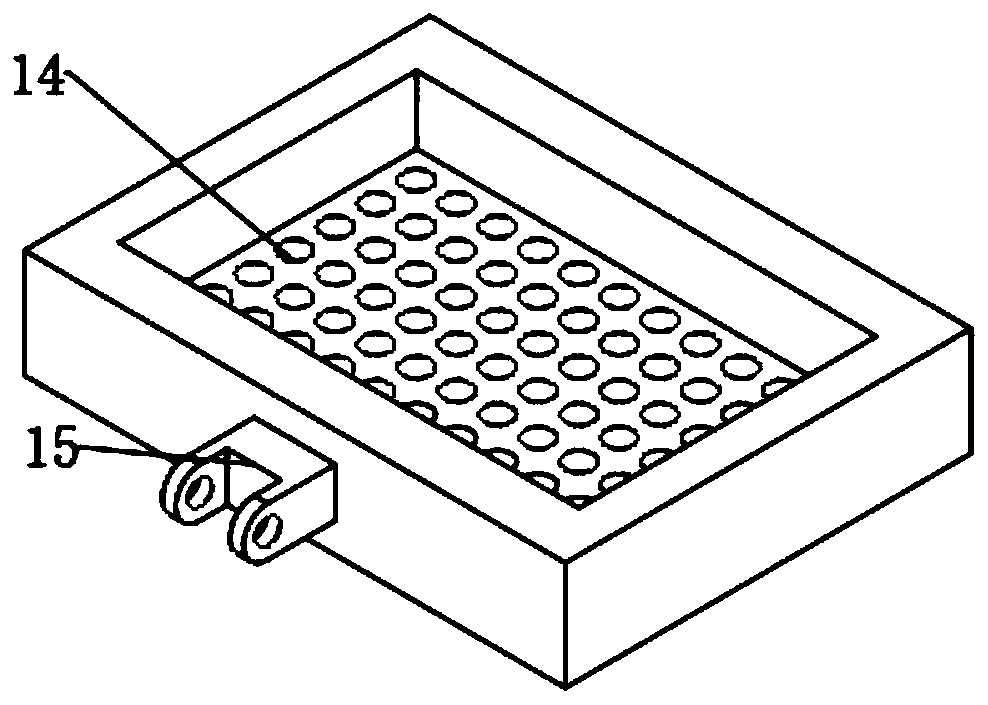

[0019] see Figure 1-3 , a corn threshing device, comprising a base 1, a cavity 4 is arranged on the base 1, a feed hopper 5 is arranged on the upper end of the cavity 4, a threshing mechanism is arranged in the cavity 4, and one side of the cavity 4 A receiving bin 2 is arranged to store corn kernels, and the receiving bin 2 communicates with the cavity 4, and a sorting mechanism is arranged in the receiving bin 2, and the corn is sorted according to the particle size; the specific structure of the threshing mechanism Without limitation, preferably, in this embodiment, the threshing mechanism includes a threshing roller 8, the threshing roller 8 is installed on the drive shaft 7, the drive shaft 7 is installed in the cavity 4 through the bearing 24, and the drive shaft 7 A driven shaft 9 is arranged on one side, and the driven shaft 9 is in transmission connection with the driving shaft 7. The second threshing roller 10 is installed on the driven shaft 9, and the second thres...

Embodiment 2

[0028] In embodiment 1, the base 1 is in direct contact with the ground during work, and in actual use, it is inconvenient to move the threshing device; therefore, this embodiment is improved on the basis of embodiment 1, and the improvements are as follows : The roller 3 that is convenient to move is arranged under the base 1, so that the described threshing device saves manpower when it is moved and placed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com