Cannonball disintegration line and disintegration method thereof

A projectile and projectile technology, which is applied to the shell decomposition line and its decomposition field, can solve the problems of general work efficiency, insufficient safety performance, and cumbersome decomposition process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

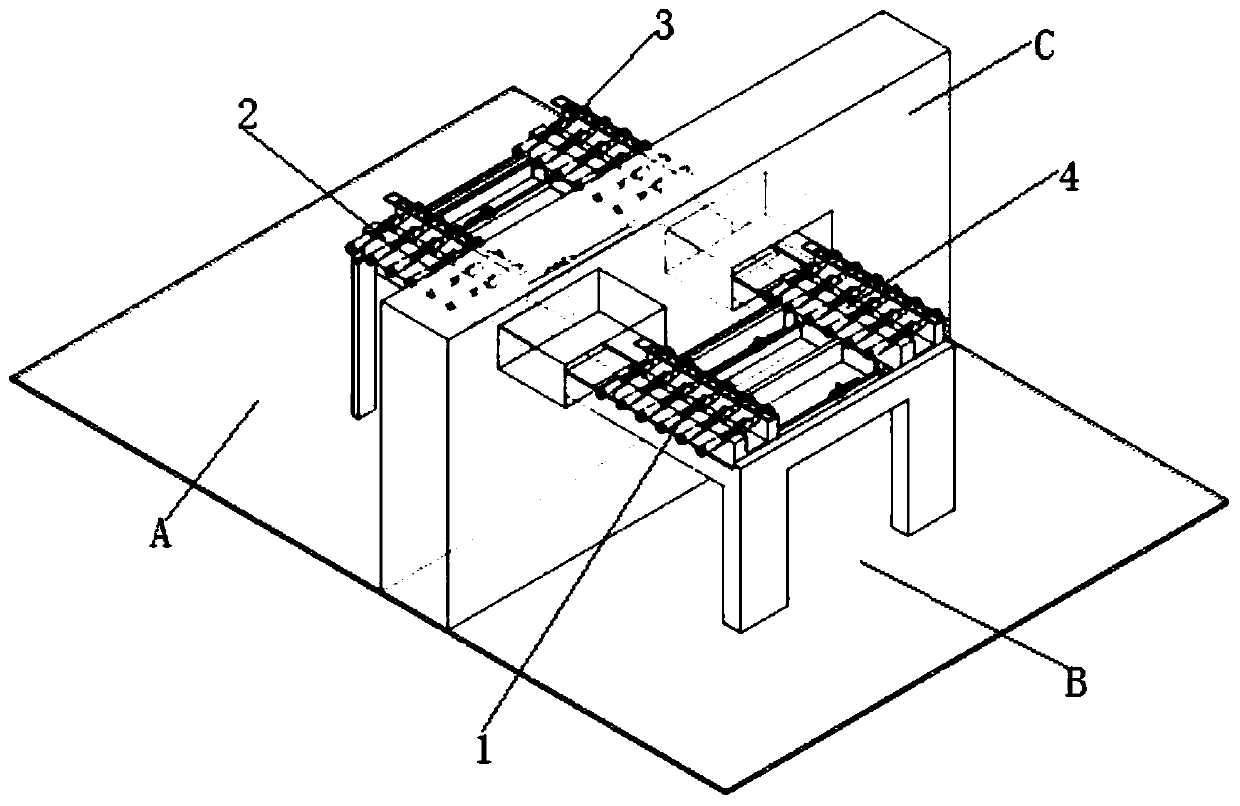

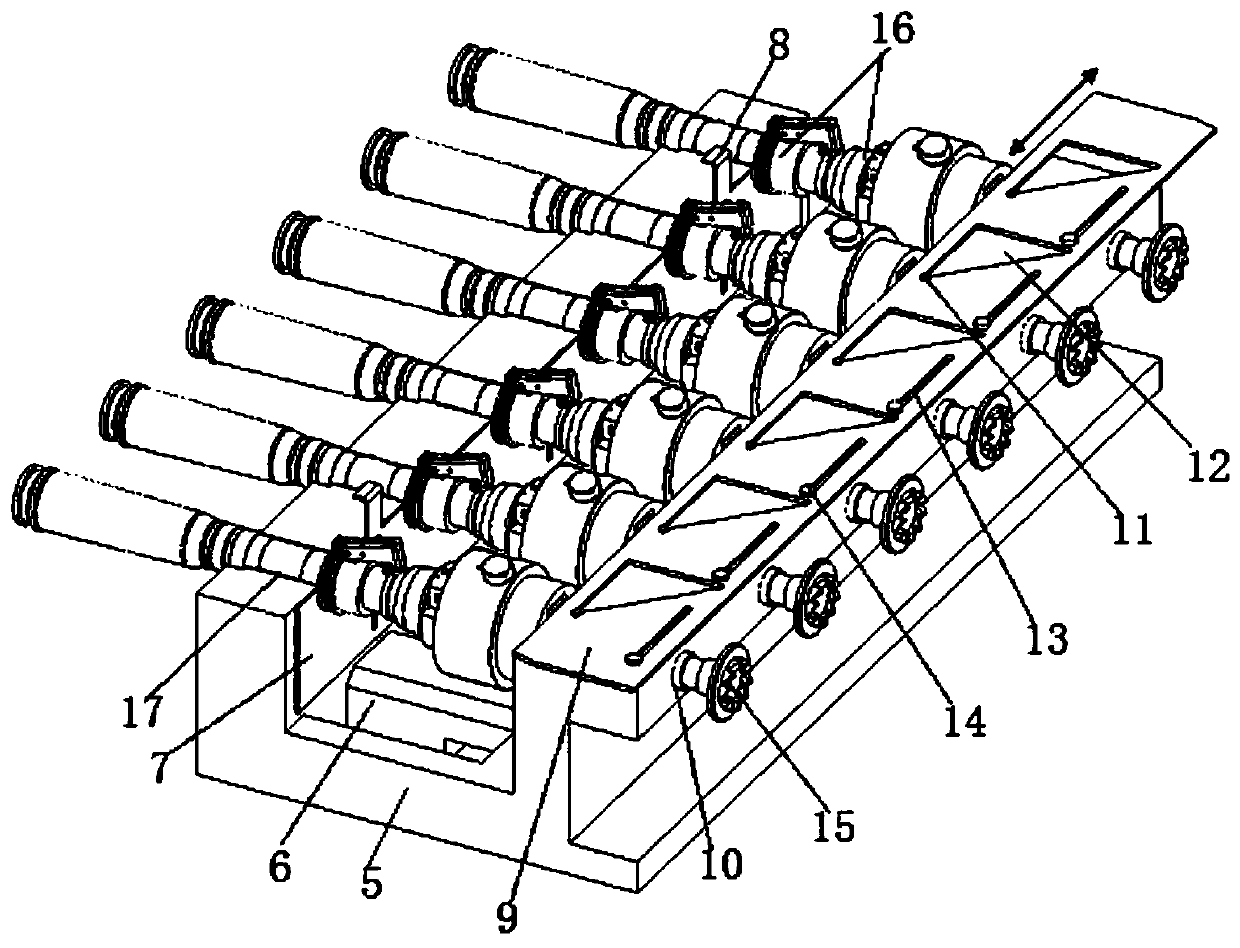

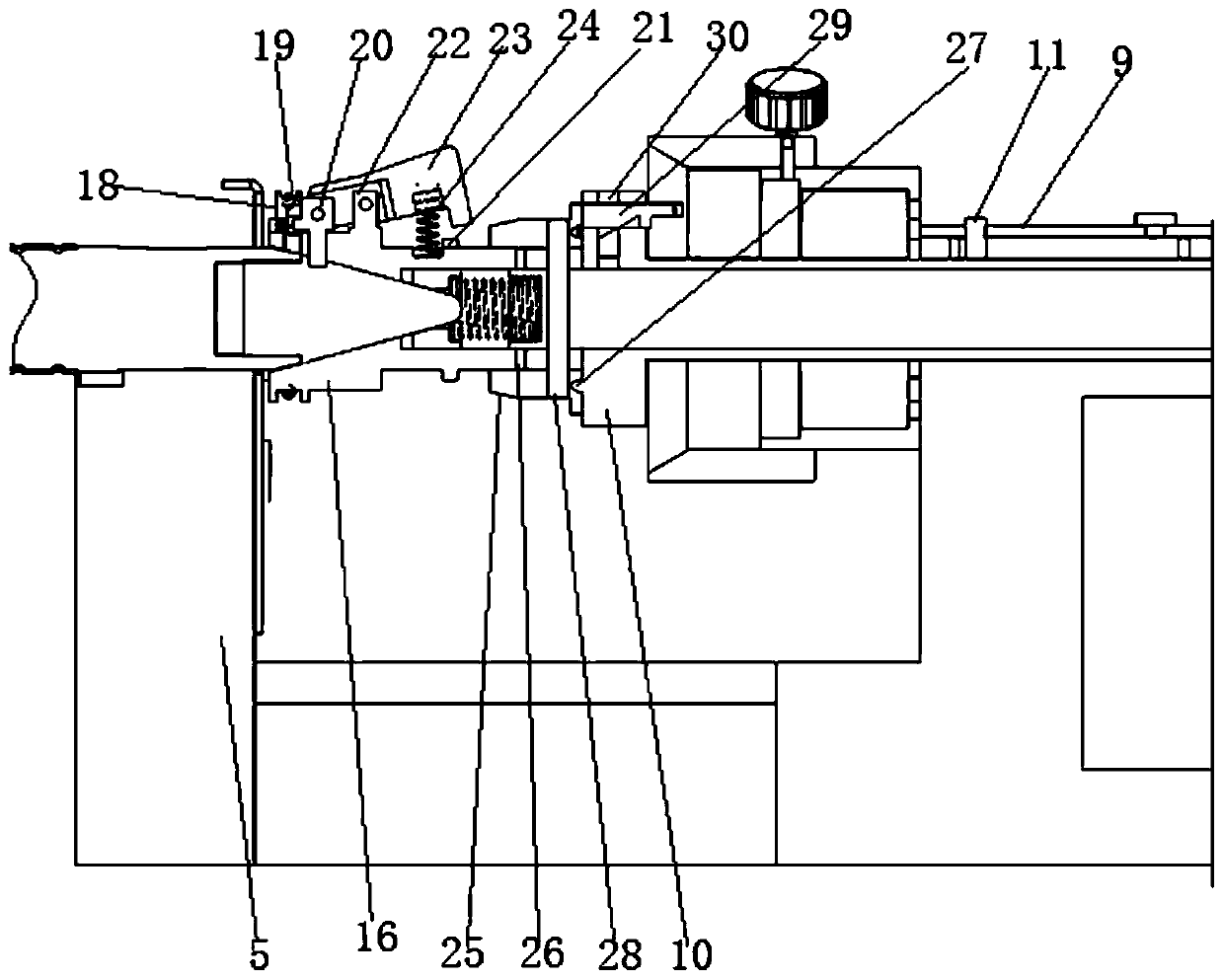

[0058] Such as figure 1 As shown, the shell decomposing line of the present invention adopts a four-station isolation operation mode; the working process is as follows: 1. the material retaining head manually installs the shell on the bomb feeding trolley at the first station, and manually rotates the shell to make the shell on the unscrewing head The unscrewing pin is inserted into the installation hole on the fuze, and the ammunition feeding trolley enters the second station through the explosion-proof window; ②The material stopper is at the second station, and the cartridge is pulled out by the manipulator for pulling out the cartridge, and the pouring of the cartridge is completed, and the cartridge and The charge slides out to the receiving box along the inclined material path; ③ After the stopper head enters the third station, the unscrewing spindle is combined with the unscrewing shaft on the ammunition feeding trolley, and the fuze is unscrewed, and the projectile and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com