Method and computer program product for operating internal combustion engine with different fuels

An internal combustion engine and fuel technology, applied in the direction of internal combustion piston engine, combustion engine, machine/engine, etc., can solve problems such as cost, increase system cost, and no identification, and achieve the effect of avoiding wrong setting and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

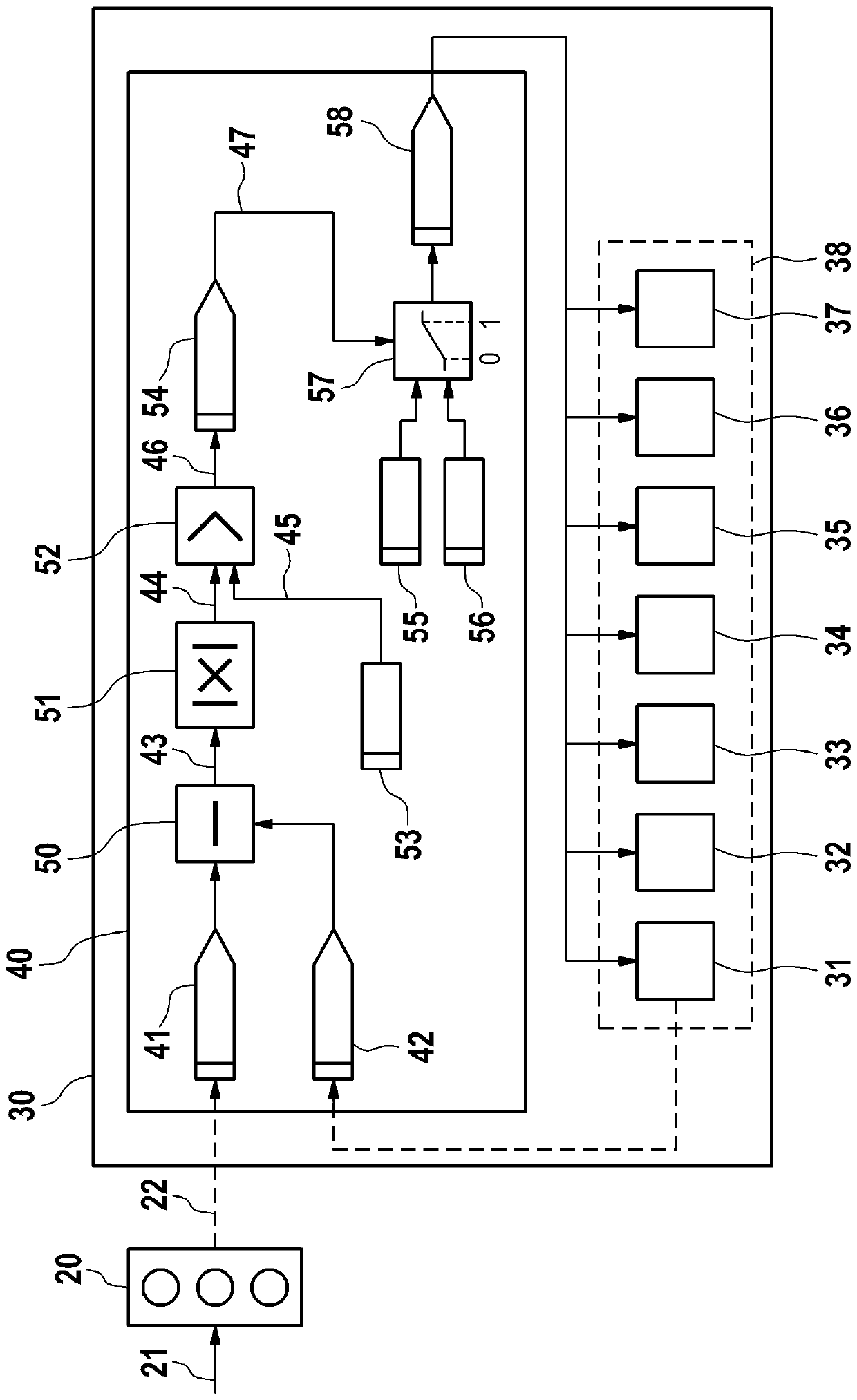

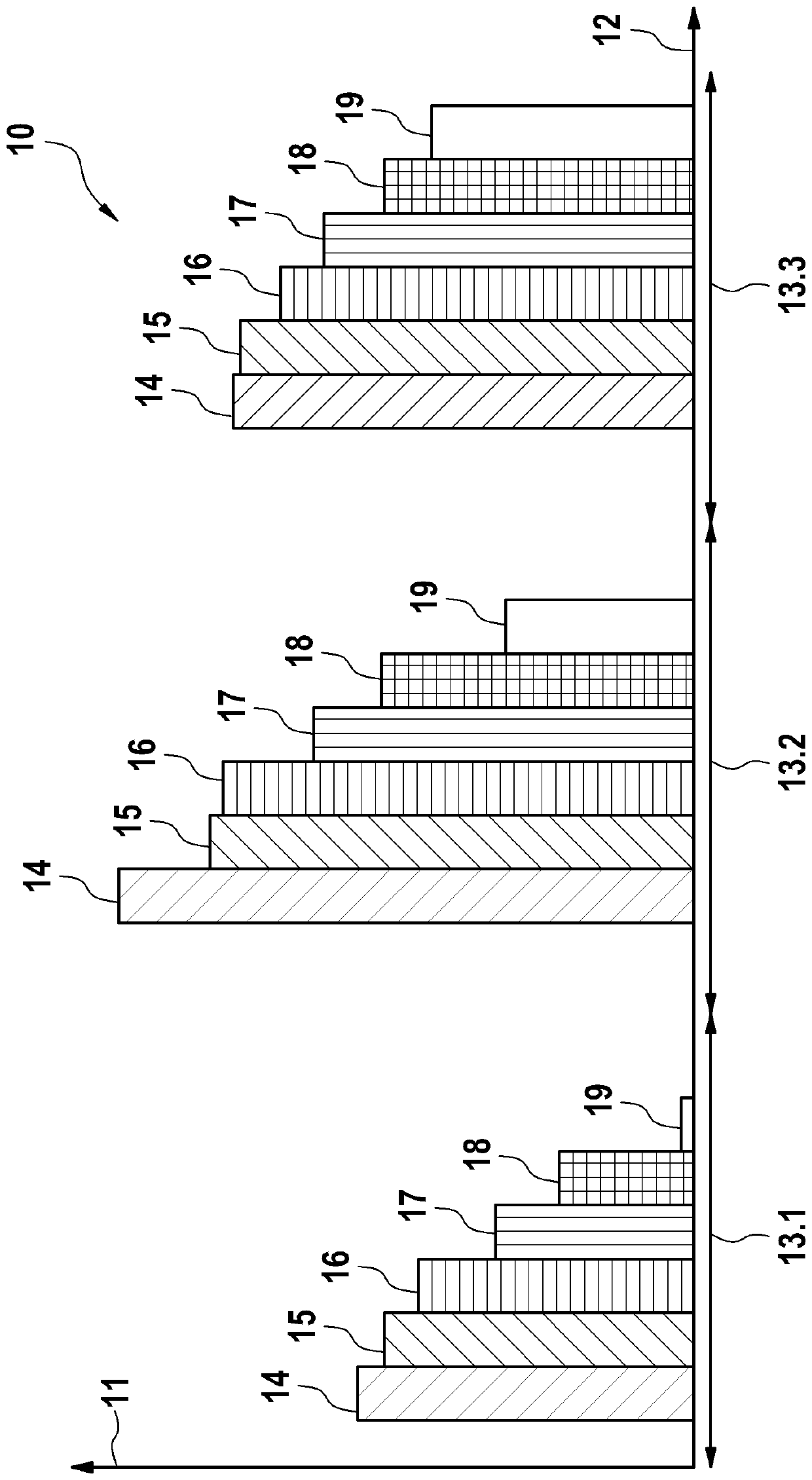

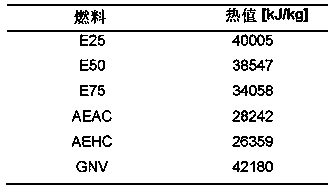

[0037] figure 1 is shown for presenting the different fuels used to run the figure 2 The histogram 10 of the exhaust gas temperature for the internal combustion engine 20 is shown in FIG. The axis of abscissa forms the rotational speed axis 12 and the axis of ordinate forms the temperature axis 11 . The rotational speed axis 12 is divided into three rotational speed ranges 13.1, 13.2, 13.3, which are marked by double arrows. For each speed range 13.1, 13.2, 13.3, for six different fuels, at figure 2 The temperature 22 of the exhaust gas shown in is shown as a bar. These fuels are E25 14, E50 15, E75 16, AEAE 17, AEHC 18 and GNV. E25 14 corresponds to a fuel mixture with 75% gasoline and 25% ethanol, E50 15 corresponds to a fuel mixture with 50% gasoline and 50% ethanol each, and E75 16 corresponds to a fuel mixture with 25% gasoline and 75% ethanol Ethanol fuel mixture. AEAC 17 (Anhydrous Ethanol Fuel) refers to alcohol (ethanol) with a maximum water content of 0.4%, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com