Hammer-type nail gun

A nail gun and hammering technology, used in nailing tools, nailing staple tools, manufacturing tools, etc., can solve the problems of operator's hand discomfort, obvious handle vibration, complicated assembly and other problems, and achieve uniform stress distribution and reduced pressure. The effect of good shock effect and good damping coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

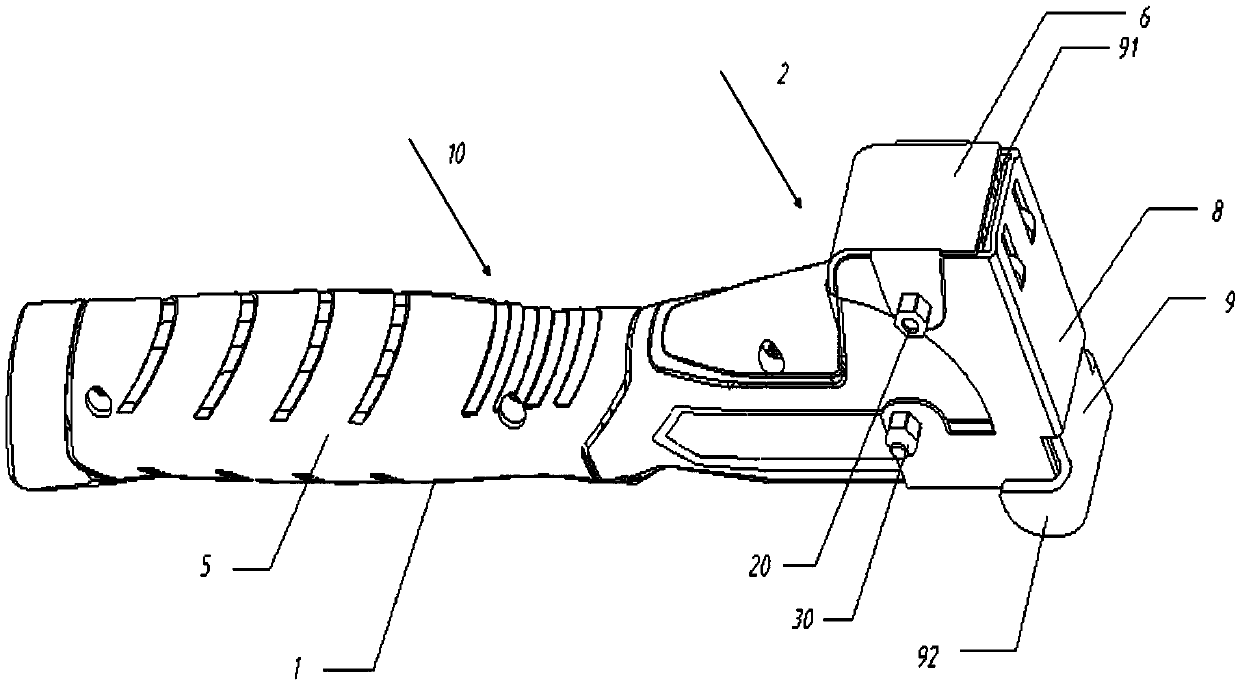

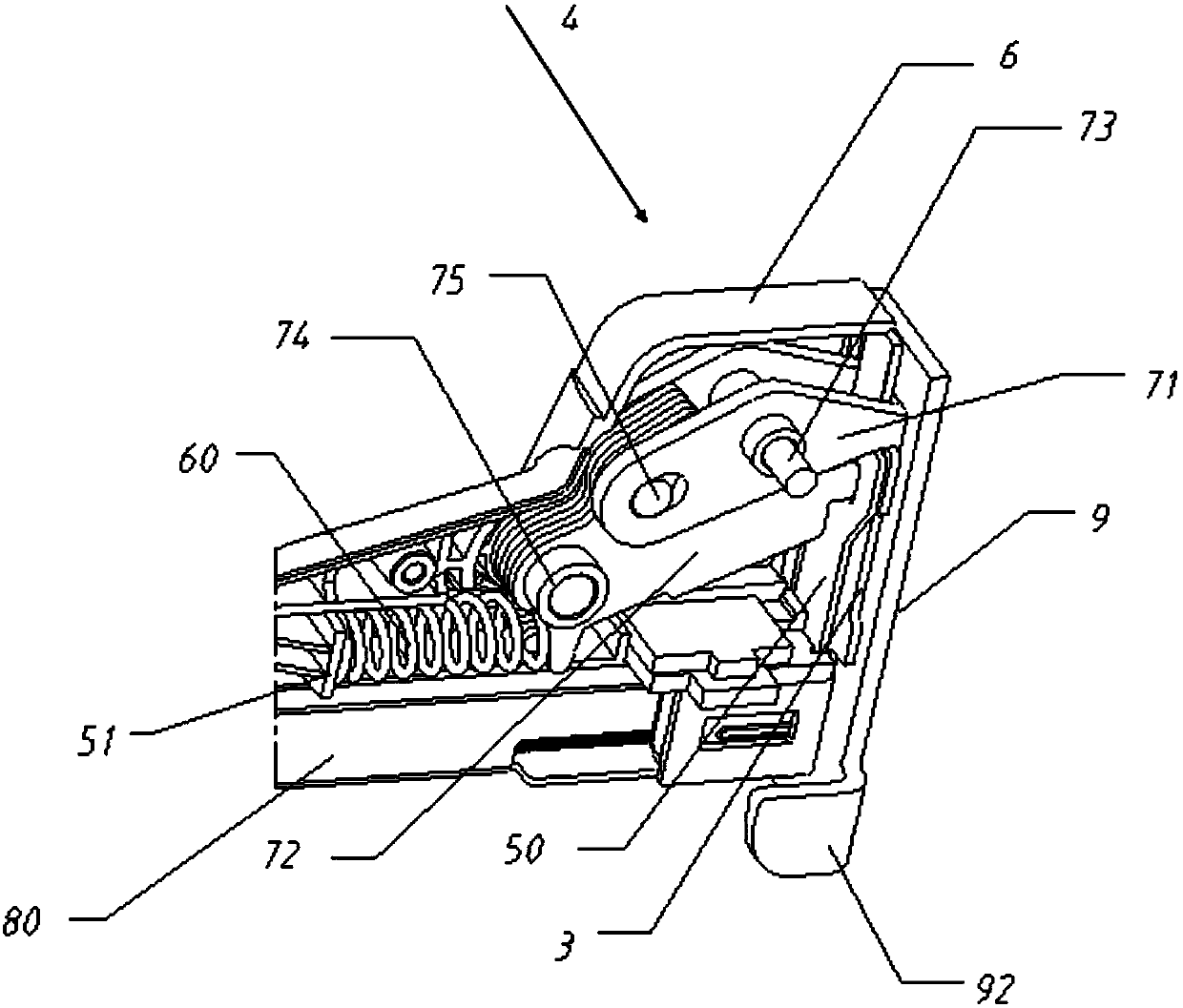

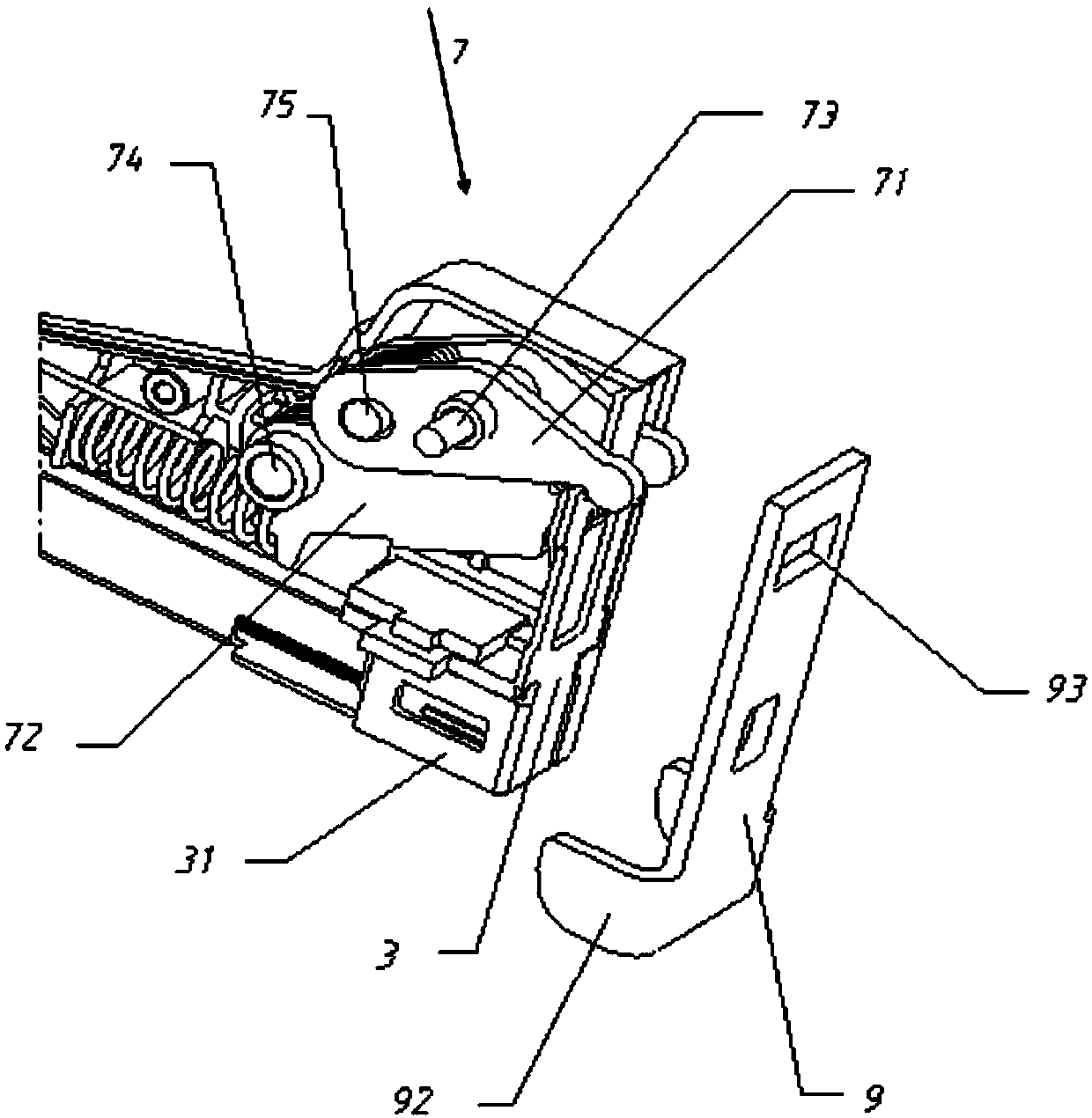

[0027] Such as figure 1 As shown, the hammer nail gun 10 includes a head 2 and a handle 1 . The handle part 1 includes an integral die-cast magnesium alloy shell 5 , and the head part 2 includes an upper cover 6 , a front cover 8 and a spike trigger 9 . The upper cover 6 and the front cover 8 are configured to be connected through fasteners 20 , and the front cover 8 and the magnesium alloy casing 5 are configured to be connected through fasteners 30 . The upper cover 6 and the front cover 8 serve as the shell of the head 2, wrapping the head 2 by fastening connection. The staple trigger 9 is located between the bulkhead 3 and the front cover 8 , and the staple trigger 9 has a bent portion 92 . In this embodiment, the curved portion 92 of the staple trigger 9 is configured to strike the workpiece 100 . In this embodiment, the front end of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com