Automatic assembly machine for door lock knob assembly

A technology for automatic assembly machines and components, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of time-consuming, labor-intensive, cost-increasing, etc., and achieve the effects of reducing costs, reducing labor costs, and improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

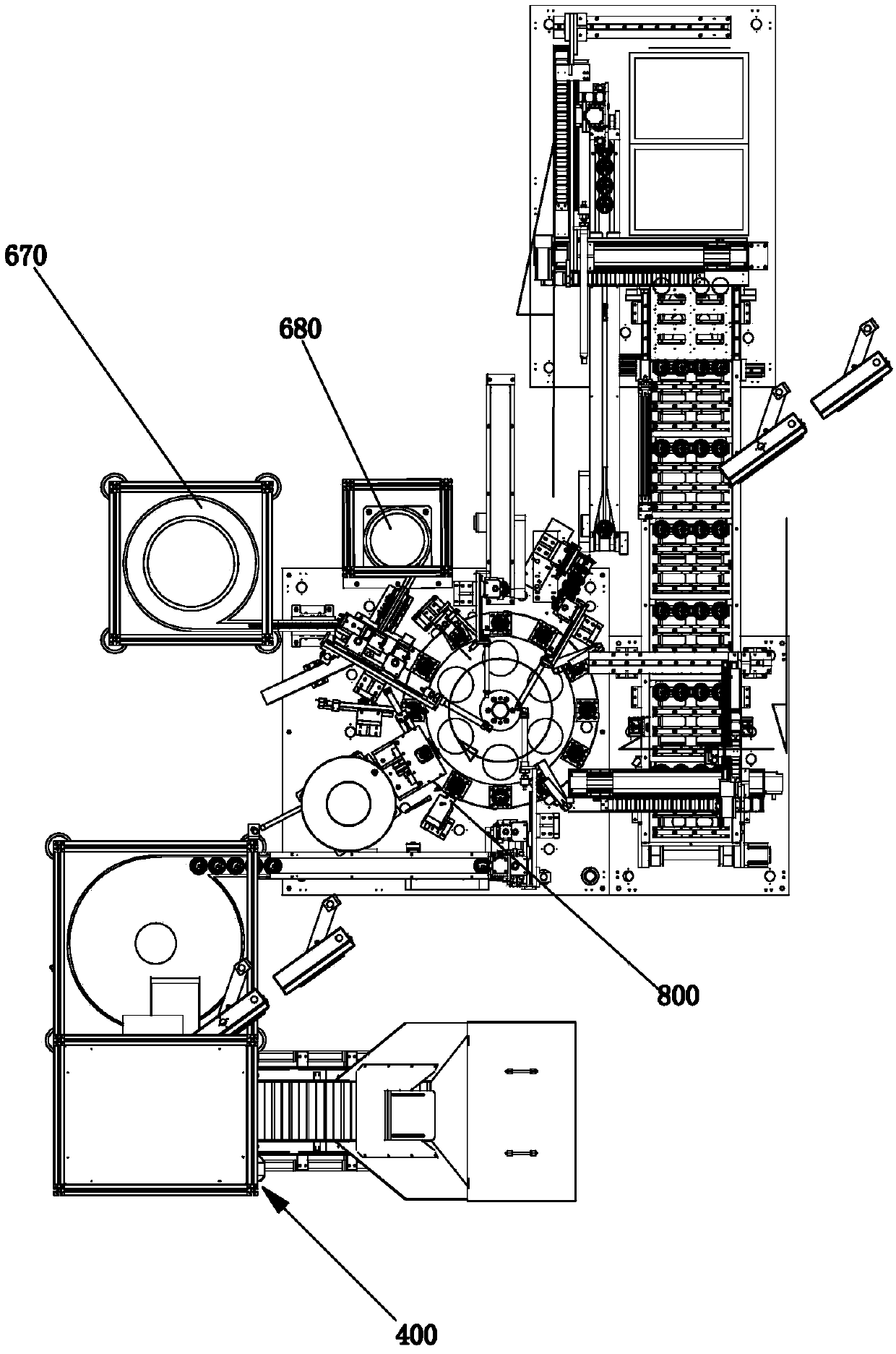

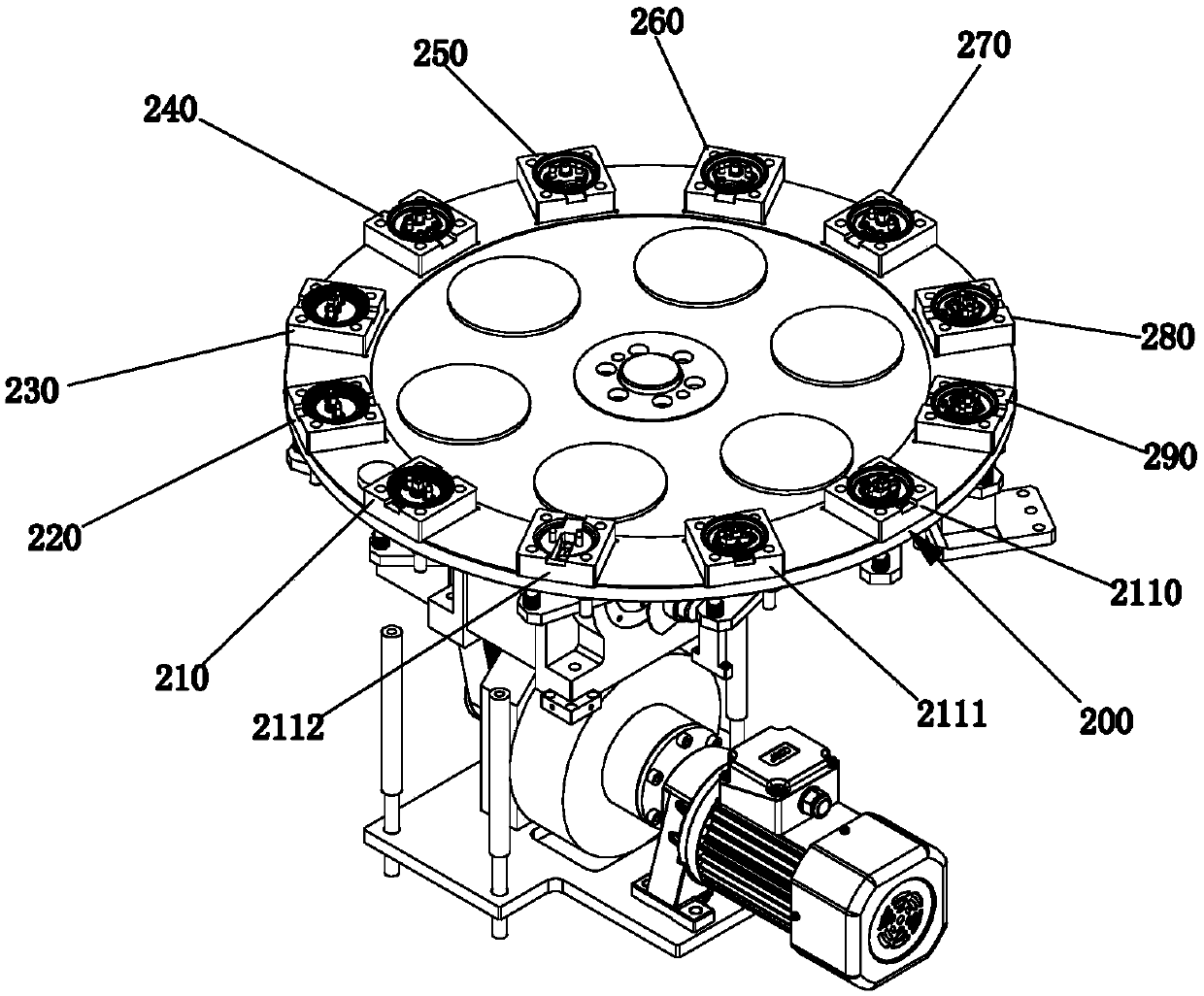

[0053] Please check Figure 1 to Figure 26 , a preferred embodiment of the automatic assembly machine for the door lock knob assembly.

[0054] The door lock knob assembly 10 includes a first assembly 3 composed of a multicolored cover 1 and a knob 2 , an inner lining cover 4 , a collar 5 , a plastic part 6 and an elastic piece 7 .

[0055] The automatic assembly machine of the door lock knob assembly includes a machine table 100, a turntable 200, a first assembly conveying mechanism 300, an inner lining cover installation device 400, a collar installation device 500, a fourth assembly installation device 600, and qualified product blanking Device 700.

[0056] The turntable 200 is rotatably installed on the machine table 100, and it is provided with at least six tooling positions arranged at intervals in a ring, and the six tooling positions are respectively the first station 210, the fourth station 240, the sixth station 260, the eighth station Station 280 and eleventh sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com