Pipeline sealant gluing device for floor heating pipeline mounting

A technology for installing sealant rings and pipes, which is applied in the direction of coating, spraying devices, and devices for coating liquid on the surface, etc. It can solve the problems of affecting the use of pipes, sealant flowing into pipes, and slow speed, so as to achieve fast glue coating, Avoid the effect of clogging the rubber tube

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

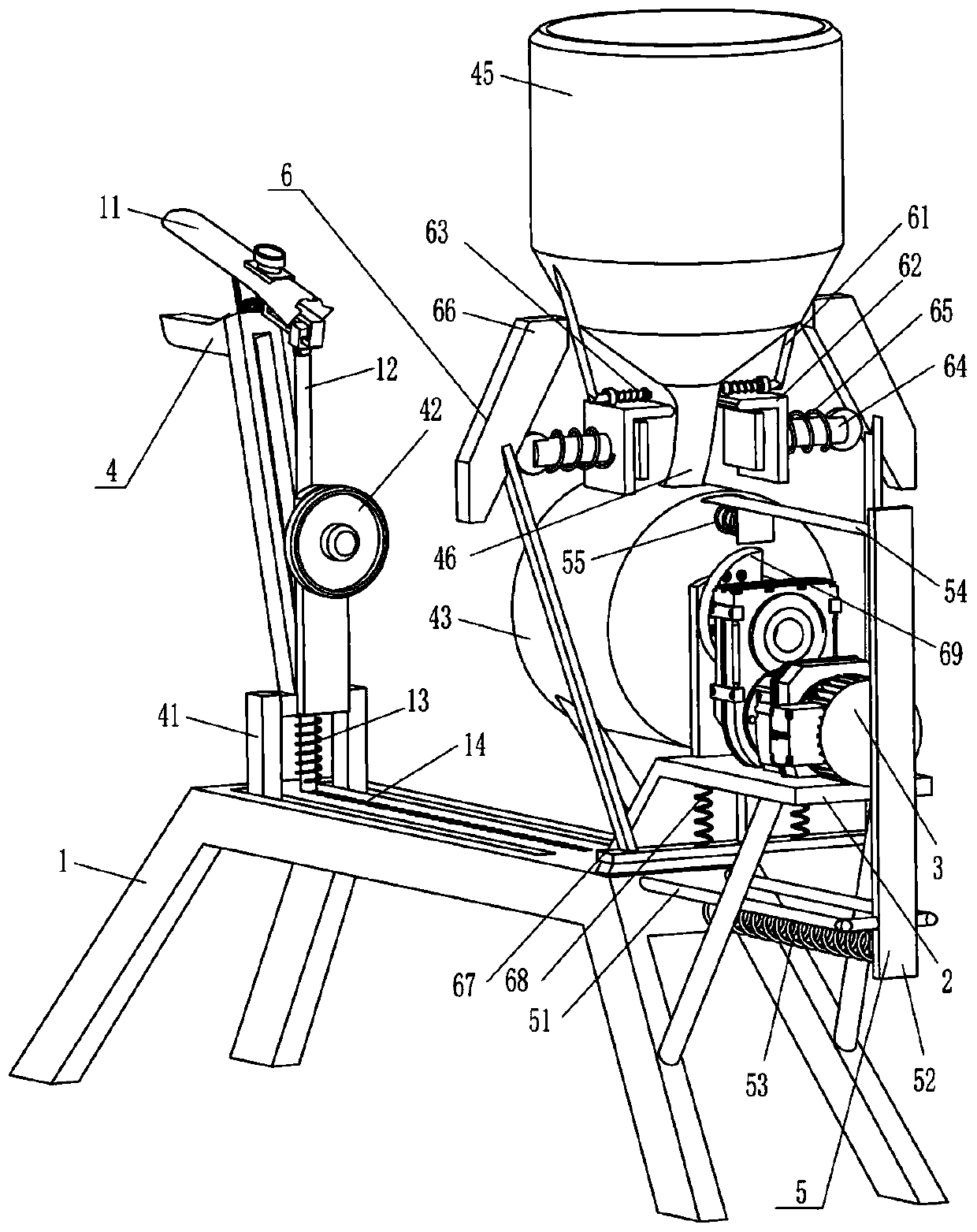

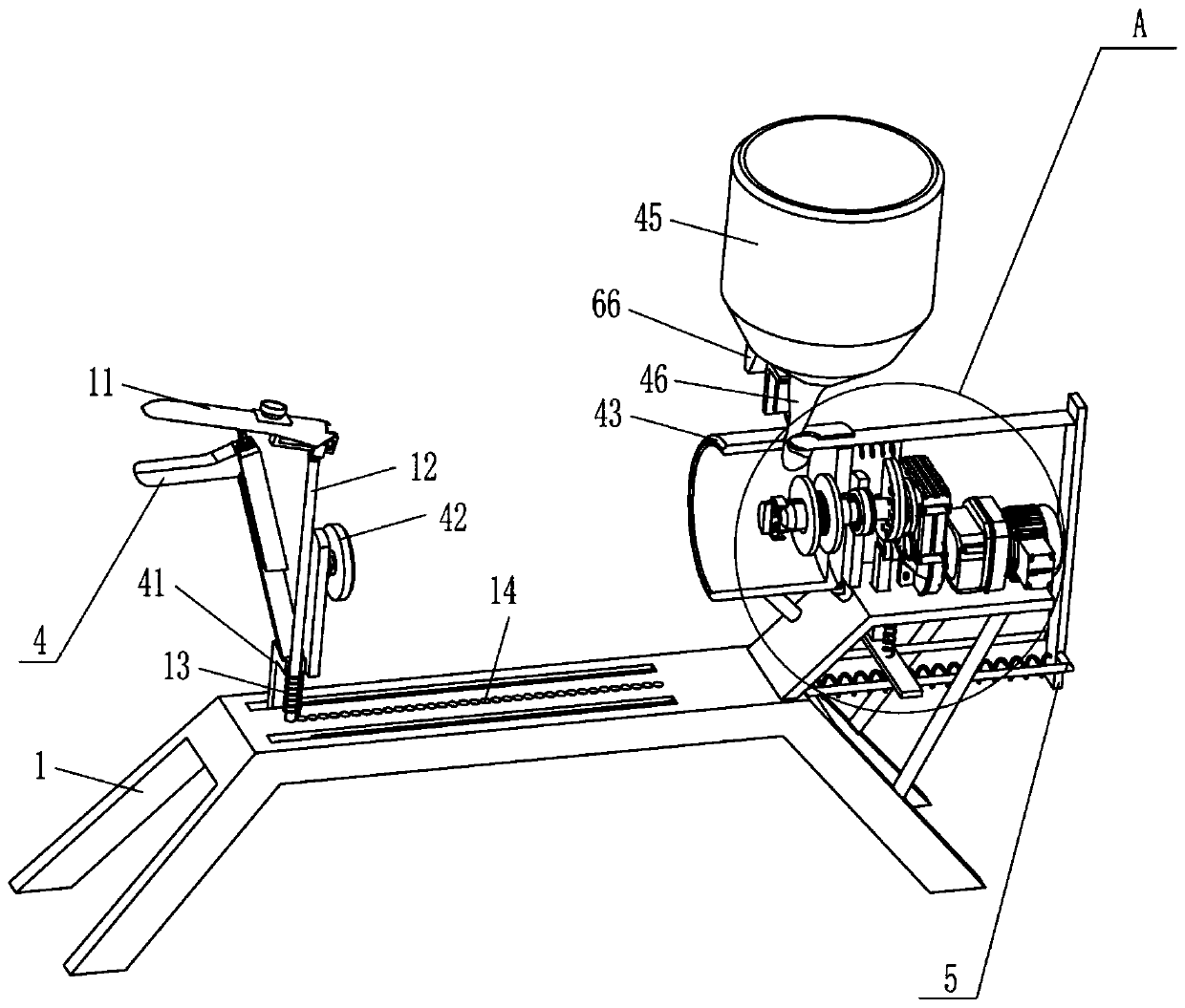

[0020] A kind of pipeline sealant ring applicator for floor heating pipeline installation, such as Figure 1-2 As shown, it includes a bottom frame 1, a mounting plate 2, a geared motor 3, a fixing device 4, and a clamping device 5. The right side of the bottom frame 1 is fixed with the mounting plate 2 through bolts, and the top of the mounting plate 2 is mounted with a geared motor through bolts. 3. The bottom frame 1 is provided with a fixing device 4 for fixing the floor heating pipeline, and the fixing device 4 is provided with a clamping device 5, and the clamping device 5 is used to block the sealant.

[0021] The fixing device 4 includes a sliding handle 41, a disk 42, a hollow tube 43, a T-shaped solid rod 44, a storage tube 45 and a rubber tube 46. The bottom frame 1 is provided with a sliding handle 41 in a sliding manner. 41 The middle part on the right side is provided with a disc 42 in a rotating manner, a hollow cylinder 43 is fixedly connected to the mounting p...

Embodiment 2

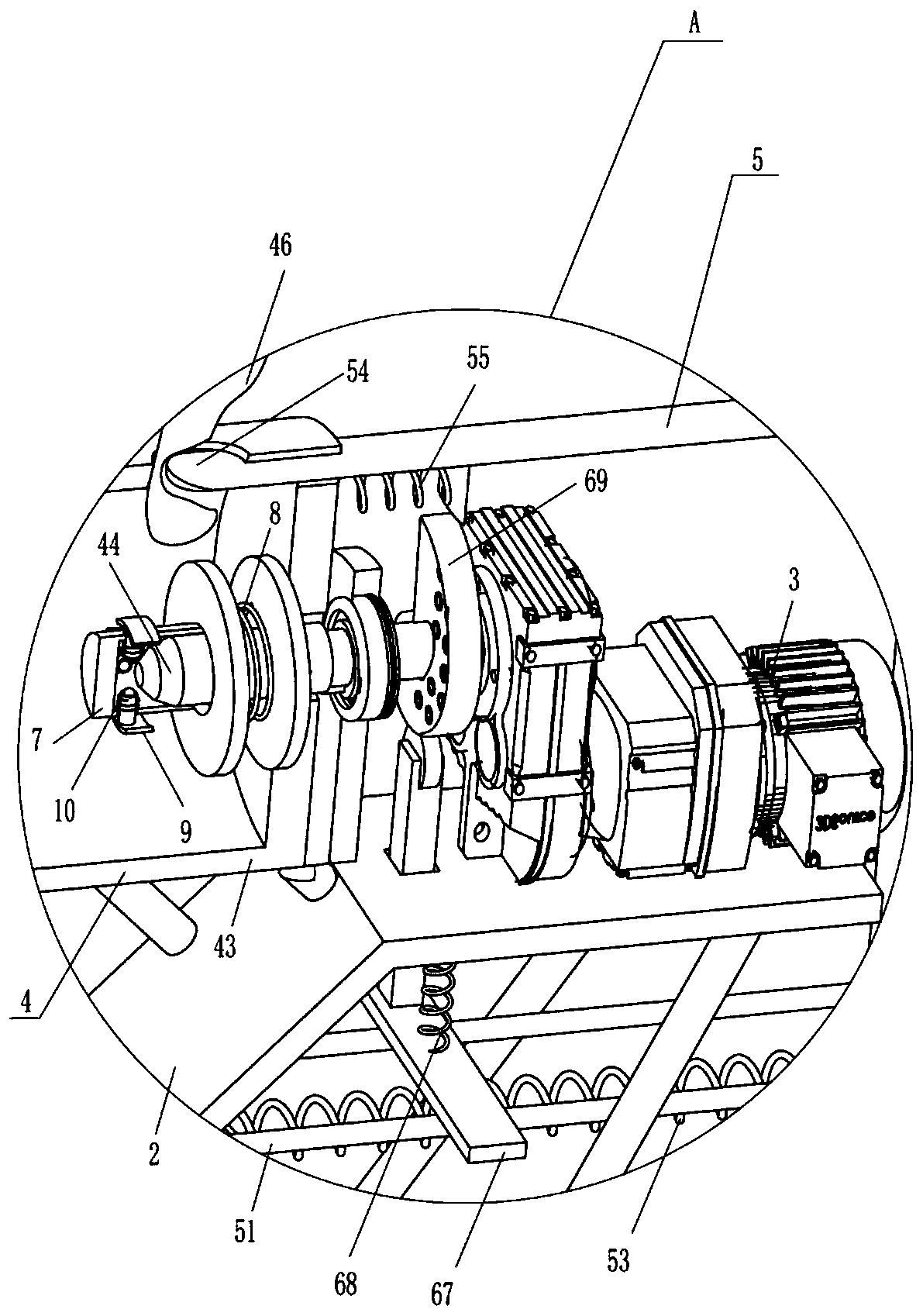

[0025] On the basis of Example 1, such as Figure 1-3 As shown, a material extruding device 6 is also included, and the material extruding device 6 includes an L-shaped slide bar 61, an L-shaped plate 62, a third spring 63, a T-shaped splint 64, a fourth spring 65, an inclined plate 66, a T-shaped plate 67, the fifth spring 68 and the cam 69, the front and rear sides of the storage tube 45 are fixedly connected with an L-shaped slide bar 61, the L-shaped slide bar 61 is slidably provided with an L-shaped plate 62, and the L-shaped plate 62 is connected to the L-shaped plate 62. A third spring 63 is connected between the sliding bars 61, and a T-shaped clamping plate 64 is slidably provided in the L-shaped plate 62, and a fourth spring 65 is connected between the T-shaped clamping plate 64 and the L-shaped plate 62. The elastic force of spring 63 is less than the fourth spring 65, and the sliding type is provided with T-shaped plate 67 on this mounting plate 2, is connected wit...

Embodiment 3

[0028] On the basis of Example 2, such as Figure 1-3 Shown, also comprise T-shaped hollow bar 7, the 6th spring 8, T-shaped clamping plate 9 and the 7th spring 10, be covered with T-shaped hollow bar 7 on this T-shaped solid bar 44, this T-shaped hollow bar 7 and The sixth spring 8 is connected between the T-shaped solid rods 44, and the T-shaped clamping plate 9 is evenly spaced and slidable on the T-shaped hollow rod 7, and the T-shaped clamping plate 9 is connected with the T-shaped hollow rod 7. There is a seventh spring 10, and the elastic force of the sixth spring 8 is greater than that of the seventh spring 10, and the inner end of the T-shaped clip 9 is in contact with the T-shaped solid rod 44.

[0029] Also includes movable handle 11, sliding lever 12 and eighth spring 13, movable handle 11 is installed with the mode of swinging on this sliding handle 41, and sliding type is provided with sliding lever 12 on this sliding handle 41, and this sliding lever An eighth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com