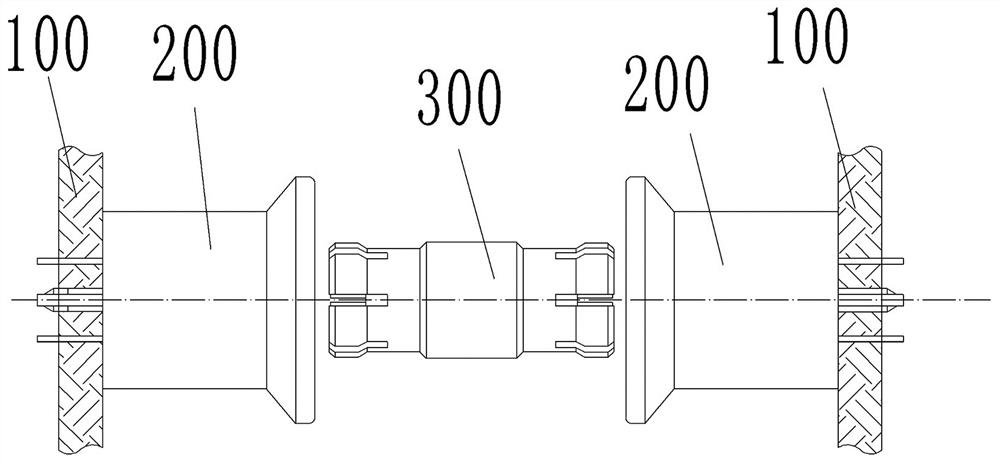

A kind of coaxial connector and connector assembly

A technology of coaxial connectors and connectors, which is applied to the parts, connections, and contact parts of the connecting device, can solve problems such as overvoltage, plastic deformation, and affecting the overall performance of the connector module, so as to avoid sudden changes in diameter, Low cost, good for high-frequency signal transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

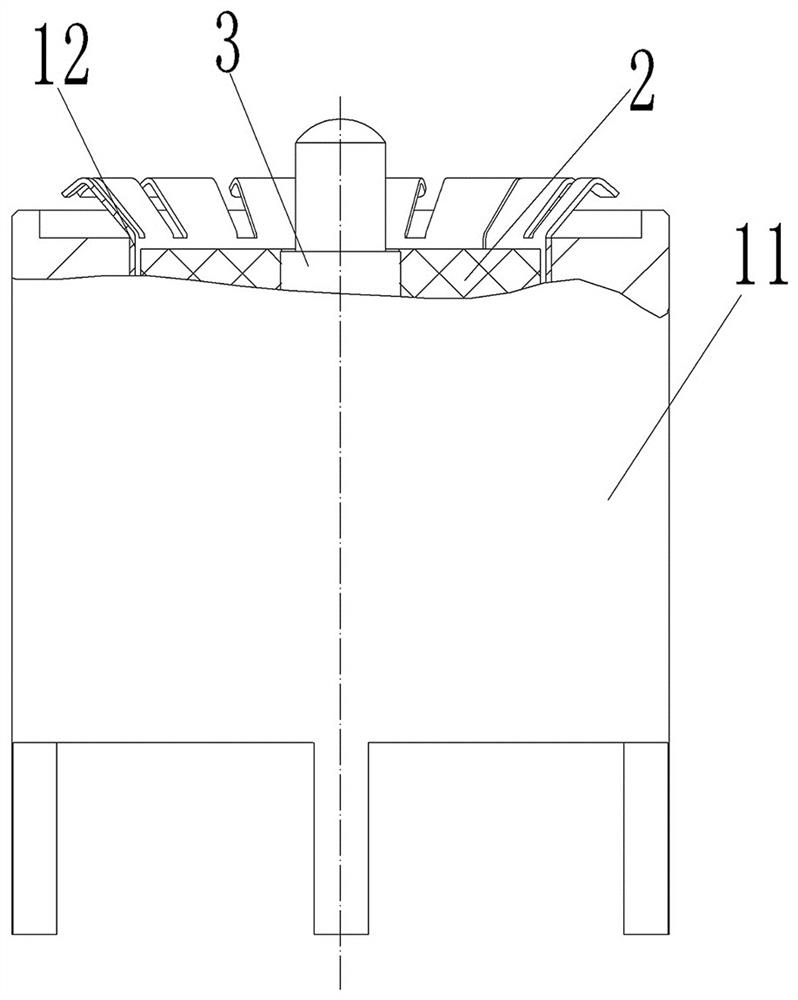

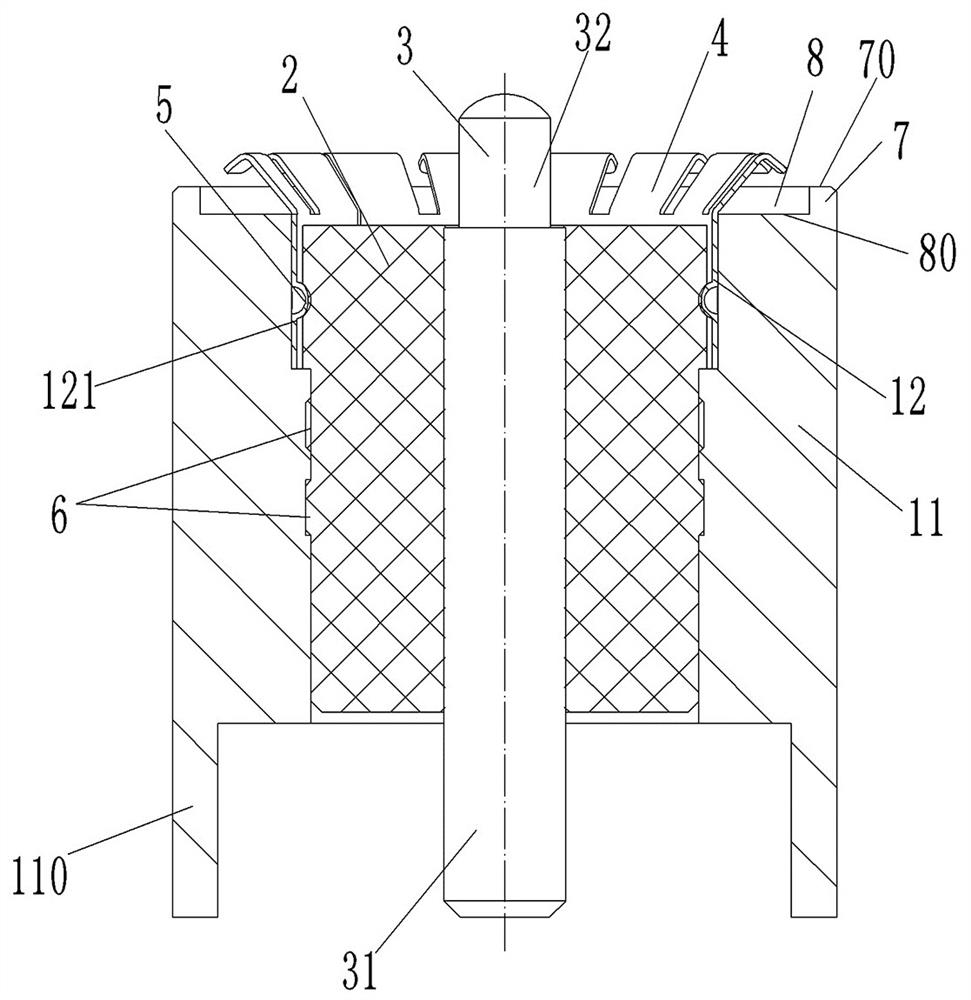

[0072] Such as Figure 2 to Figure 5 As shown, in this embodiment, the coaxial connector includes an outer shell 11 , an inner insulator 2 , a central conductor 3 and an outer contact conductor portion 12 . Specifically, the central conductor 3 is fixed in the inner insulator 2, the outer shell 11 is a conductor, the inner insulator 2 is tightly fitted and fixedly inserted in the outer shell 11, and the outer contact conductor part 12 is inserted in the inner insulator 2 and the outer shell 11. Between, so that the outer contact conductor part 12 and the outer shell 11 are conductively fixed together, and then realize the separate conductive connection of the outer shell 11 and the outer contact conductor part 12 .

[0073] Such as image 3 As shown, the rear end of the center conductor 3 is a center conductor fixed part 31, and the front end is a center conductor floating part 32. The center conductor fixed part 31 is used to be fixedly connected to a corresponding connector...

specific Embodiment 2

[0097] Such as Figure 6 As shown, compared with the coaxial connector structure in Embodiment 1, the main difference lies in that the outer contact shrapnel of the outer contact conductor part in Embodiment 1 are all folded outwards, while the outer contact shrapnel of the outer contact conductor part 400 in Embodiment 2 The contact springs 401 are all folded inwards. At this time, it should be noted that the outer contact springs can be designed to be tapered to avoid accidental interference when they are folded.

[0098] In this embodiment, all the inwardly folded outer contact shrapnels are obliquely folded so as to form a trumpet-like structure with gradually changing diameters as a whole, so as to obtain better gradually changing impedance. In other embodiments, the inverted outer contact elastic piece can also be in the shape of a broken line, forming a sudden change, as long as it has sufficient elastic pressing force.

[0099] During installation, the outer contact c...

specific Embodiment 3

[0103] Such as Figure 7 As shown, compared with the coaxial connector structure in Embodiment 1, the main difference is that the front end stop surface in Embodiment 1 is set at the front end of the outer shell, while the front end stop surface 104 in this embodiment is set at The front end of the internal insulator 103 can also be matched with the movable PCB board as the target connector to limit the corresponding crimping range.

[0104] Same as Embodiment 1, in this embodiment, the outer contact shrapnel of the outer contact conductor part 105 is also folded outwards, and an outer rear positioning surface 102 is provided at the front end of the outer shell 101 to stop with the front end on the above-mentioned inner insulator 103. The surface 104 is misplaced to form an avoidance space to ensure the normal deformation of the external contact shrapnel after being compressed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com