Support for testing optical fiber gyroscope

A fiber optic gyroscope and screw technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of inconvenient clamping and positioning of fiber optic gyroscopes, and achieve the effects of improving clamping protection capabilities, convenient use, and avoiding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

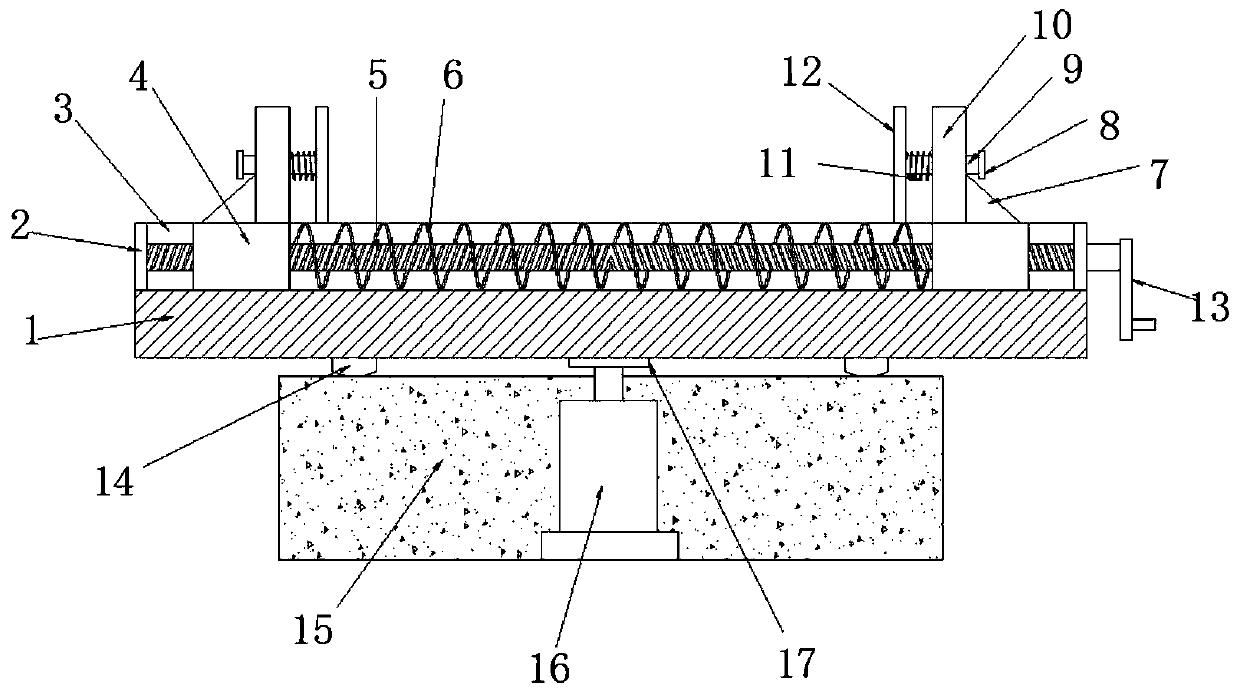

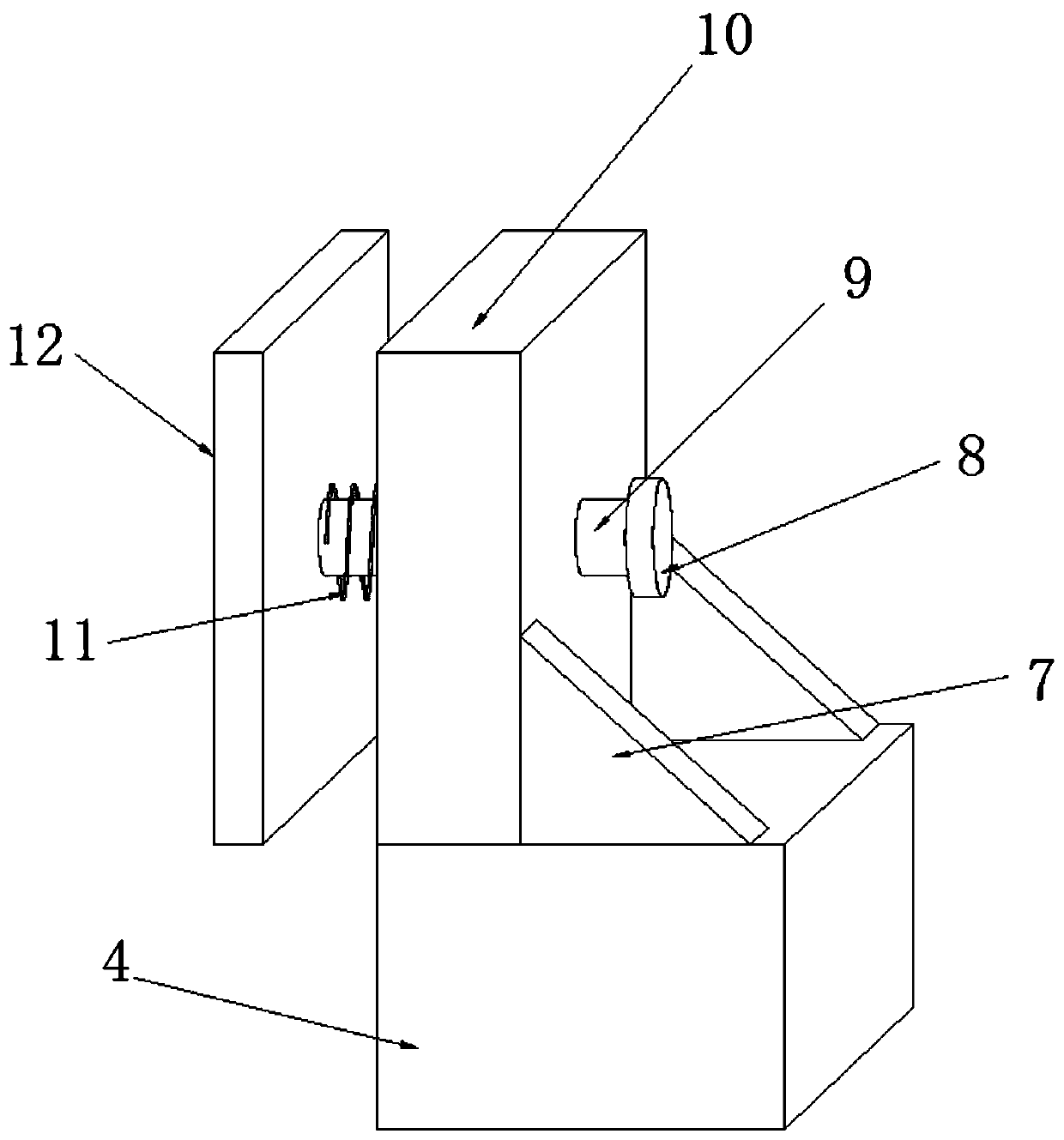

[0024] refer to figure 1 and figure 2 , a bracket for fiber optic gyro testing, including a storage board 1, a chute 3 is opened on the outer wall of the top of the storage board 1, and both ends of the chute 3 are fixed with fixed plates 2, and two fixed plates 2 are rotated and inserted with screw rods 5. There are two sections of thread in opposite directions on the screw 5, and the two sections of the screw 5 are both threaded with a slider 4 that forms a sliding fit with the chute 3, and the support spring 6 is sleeved on the screw 5, and the support spring 6 is located at the Between the two sliders 4, a support plate 10 is fixed on the top of the slider 4, and a movable rod 9 is movably inserted on the support plate 10, and the two ends of the movable rod 9 are respectively fixed with a limit block 8 and a clamping plate 12, and the movable rod 9 A clamping spring 11 is sleeved on one end close to the clamping plate 12 .

[0025] One end of the screw rod 5 is fixed w...

Embodiment 2

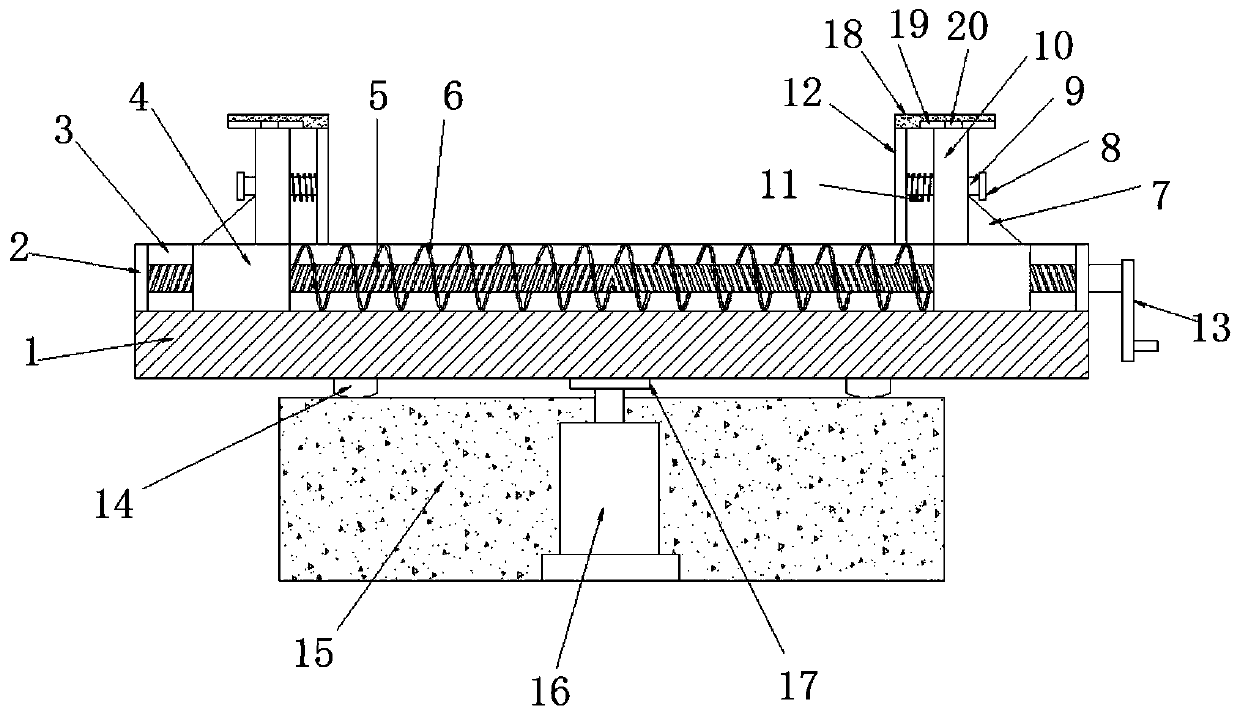

[0028] refer to image 3 , a bracket for fiber optic gyro testing. The difference between this embodiment and Embodiment 1 is that a guide plate 18 is also fixed on the top outer wall of the clamping plate 12, and the bottom outer wall of the guide plate 18 is attached to the top outer wall of the support plate 10, and the guide plate 18 A guide groove 19 is formed on the outer wall of the bottom, and a guide block 20 is fixed on the top of the support plate 10 to form a snap fit with the guide groove 19 .

[0029] The working principle of this embodiment: the guide plate 18 can form a relative slide with the top of the support plate 10 when the clamping plate 12 performs clamping work, and play a position-limiting guiding role for the clamping plate 12 to improve the stability of the clamping work, while The guide block 20 can cooperate with the guide groove 19 on the guide plate 18 to limit and guide the guide plate 18 to improve the stability of the lateral movement of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com