Yarn rubbing plate for spinning frame keel fender

A spinning frame and dragon tendon technology, applied in textiles and papermaking, etc., can solve problems such as difficult cleaning of brush hairiness, broken yarn, easy curling of brush hairs, and short service life, achieving fast cleaning efficiency, increased service life, and convenient fixing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0022] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

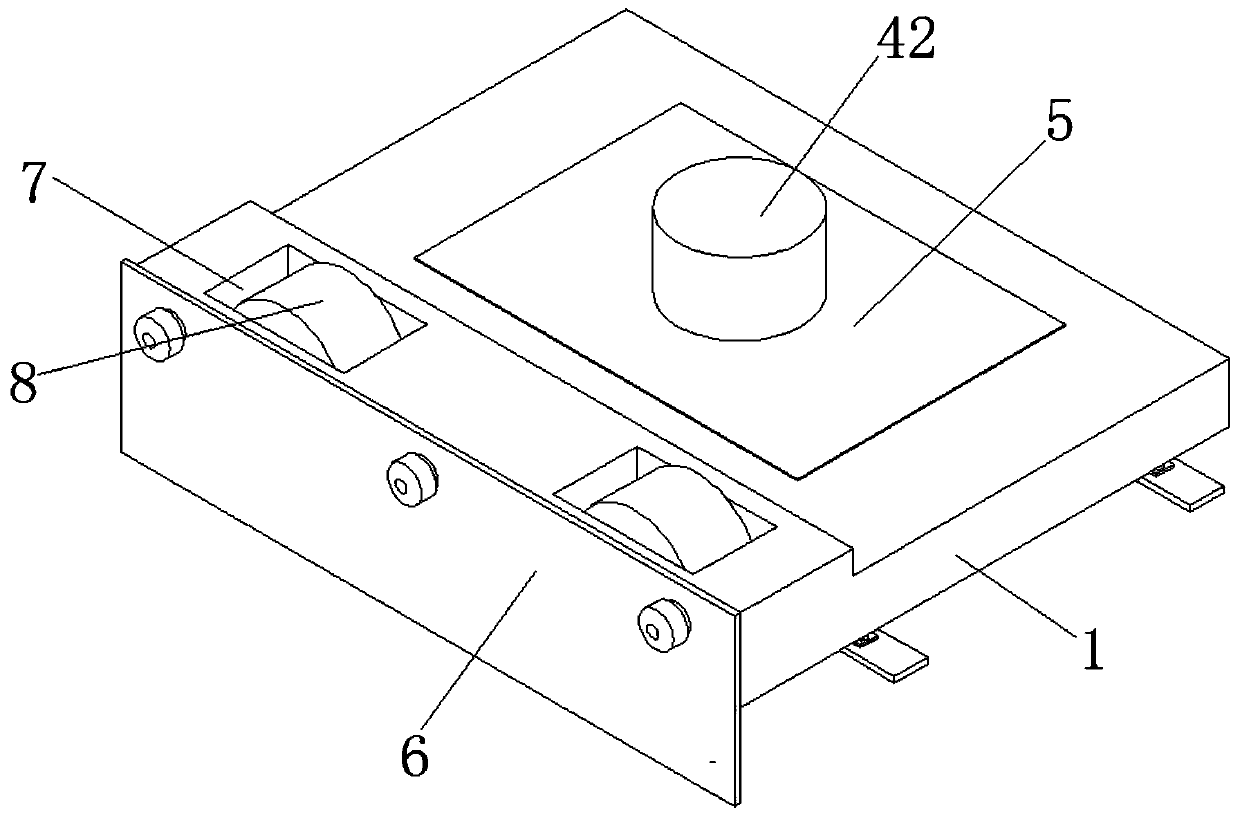

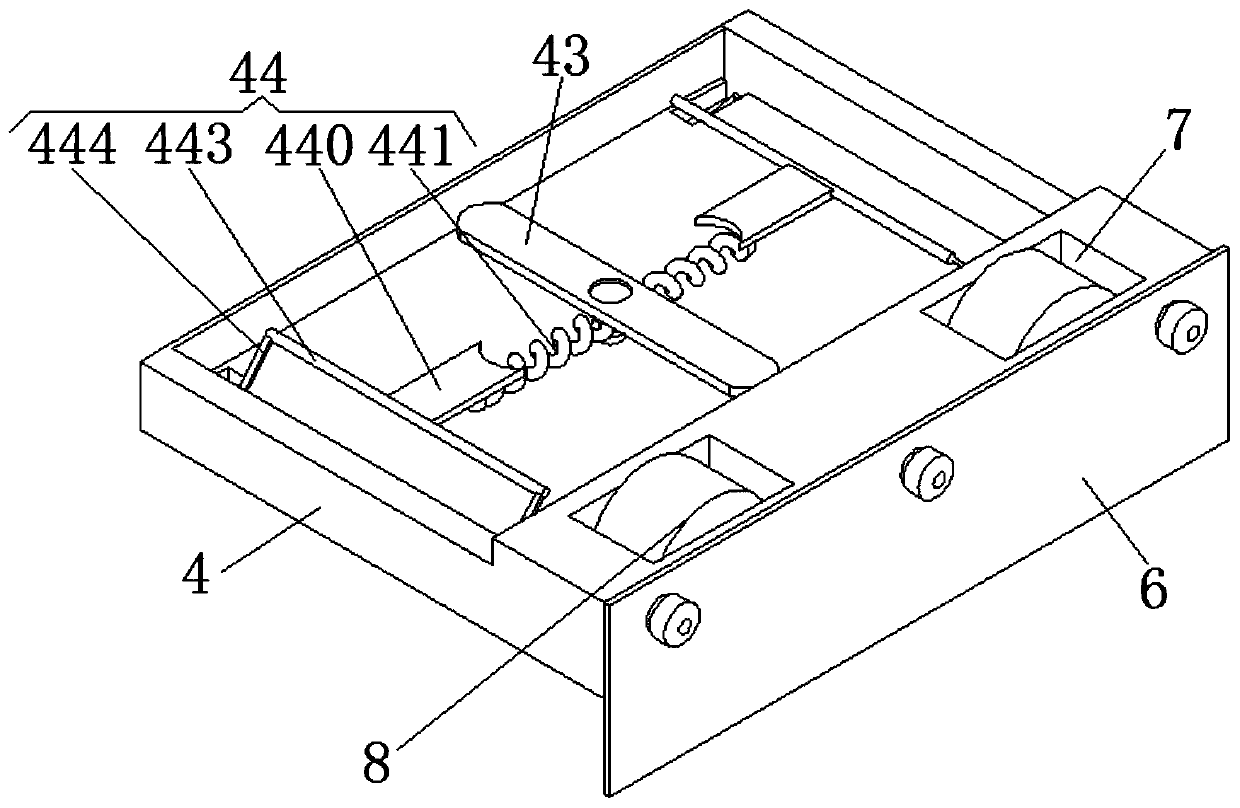

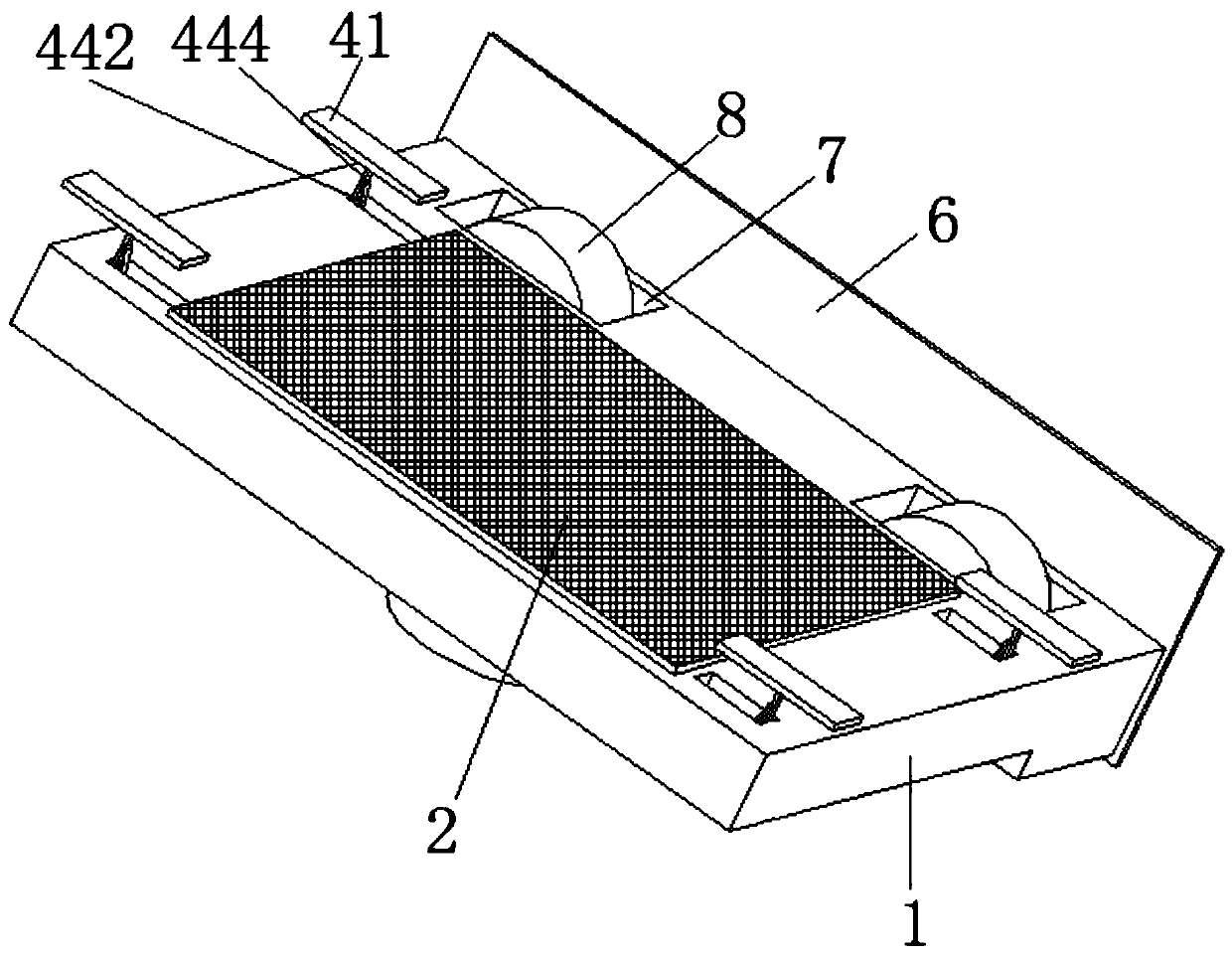

[0023] The embodiment of the present invention provides a yarn wiping board used for the splint of a spinning frame, such as Figure 1-4 As shown, the plate body 1 is included. The plate body 1 is made of nylon material by die-casting, which has the function of resisting falling and not deforming.

[0024] The surface of the board 1 is glued with Velcro 2. By setting the Velcro 2, it is convenient to replace the cleaning flannel 3, and the mounting plate 41 is set around the Velcro to facilitate the fixing of the cleaning flannel 3, and the surface of the Velcro 2 is sticky. With cleaning flannel 3, the cleaning flannel 3 replaces the traditional brush, which not only has fast cleaning efficiency, but also can be detached and cleaned, which increases the service life.

[0025] The cle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com