Body anti-collision structure

A body and side panel technology, which is applied in the field of body side impact structure, can solve the problems of inability to solve potential safety hazards, affecting the safety of drivers and passengers, and the limited effect of side impact impact force, so as to improve the side impact resistance and protection of the body. Cabin safety and the effect of strengthening support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further illustrate the technical means and effects adopted by the present application to achieve the intended invention purpose, the following is a detailed description of the present application in combination with preferred embodiments.

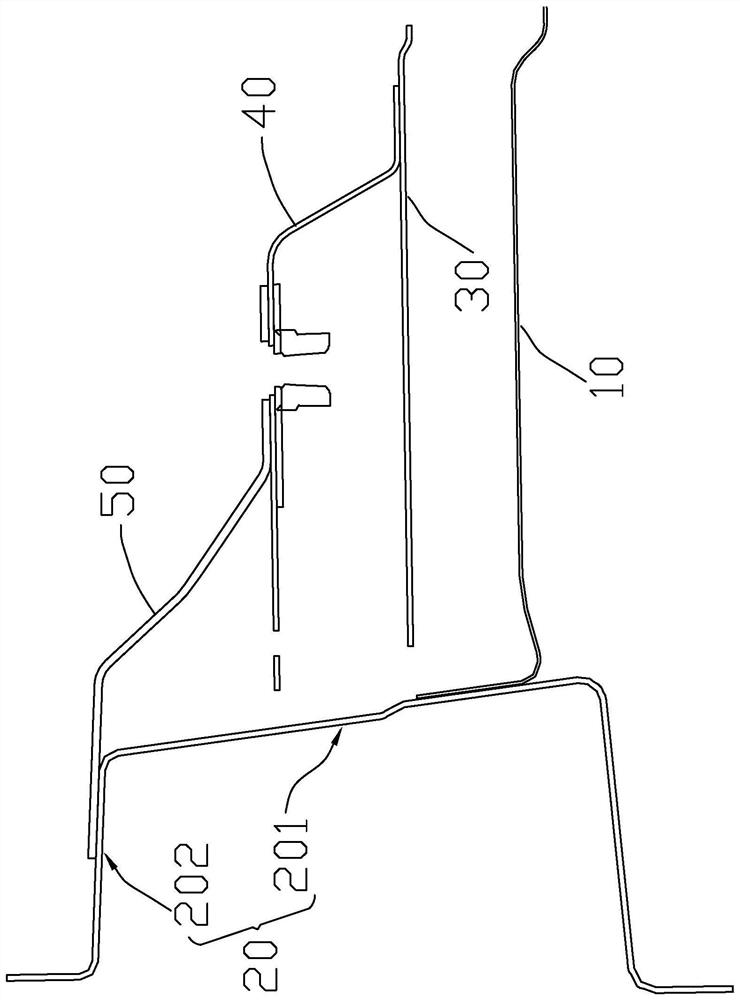

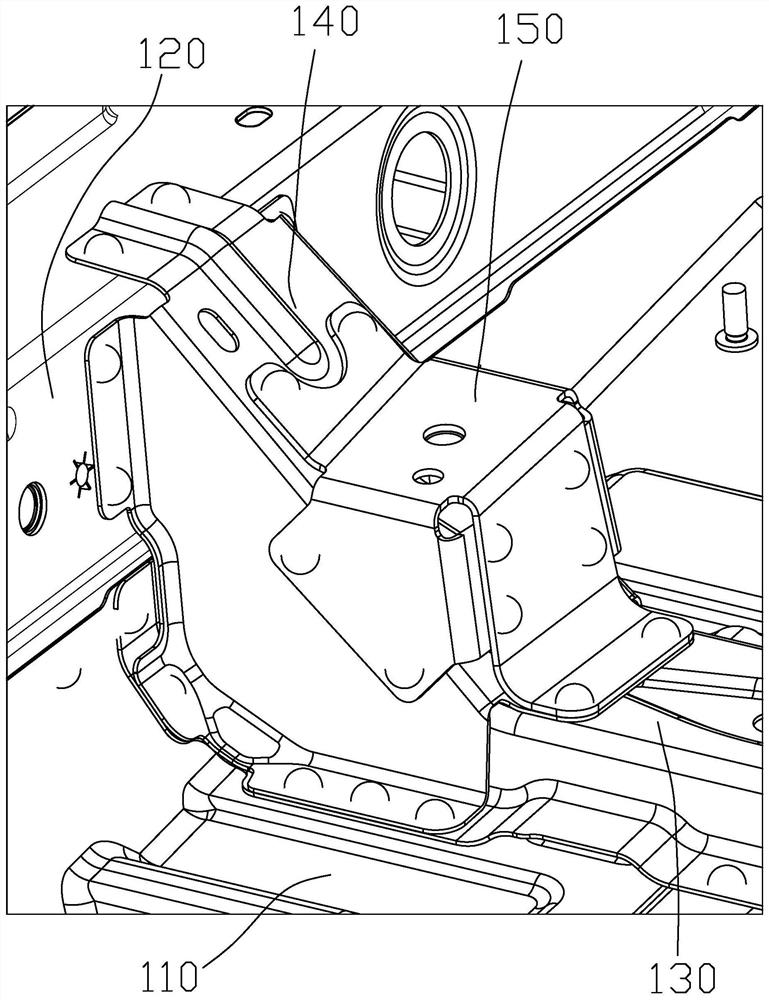

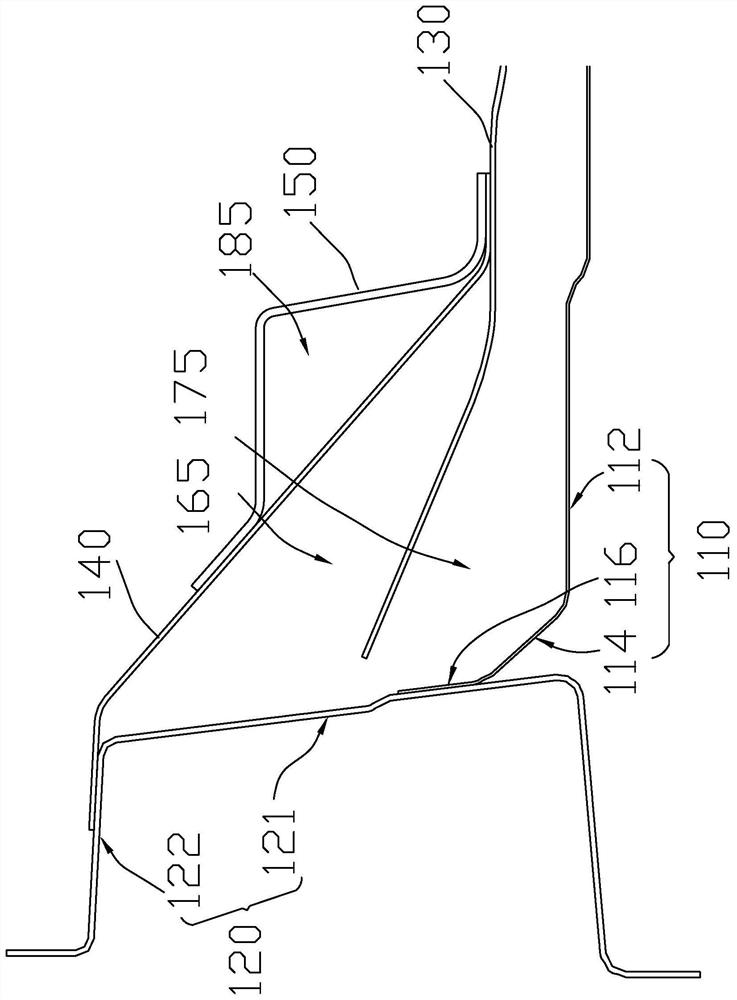

[0025] figure 2 Shown is a three-dimensional schematic view of the anti-side impact structure 100 of the vehicle body of the present application. image 3 Shown is a schematic cross-sectional view of the anti-collision structure 100 of the vehicle body. Such as figure 2 and image 3 As shown, the body side anti-collision structure 100 includes a floor 110, a door sill 120, and a seat mounting beam 130. The door sill 120 includes a side plate 121 and an upper plate 122. The floor 110 is connected to the side plate 121 of the door sill 120. The seat The installation beam 130 is fixed on the floor 110 . The body anti-side impact structure 100 also includes an anti-side impact support plate 140 and a seat mounting brack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com