Carton printing device capable of automatically adding ink at regular time

A carton printing and automatic ink filling technology, applied in printing devices, printing, printing machines, etc., can solve problems such as excessive use of ink for printing, inability to automatically ink, unevenness, etc., and achieve stable printing and clear fonts or patterns. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

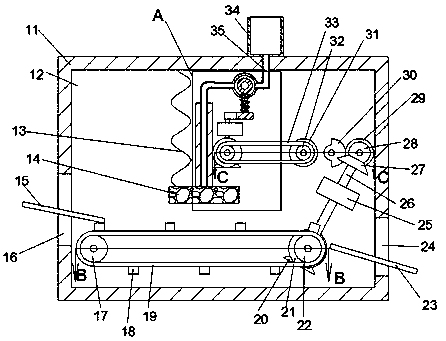

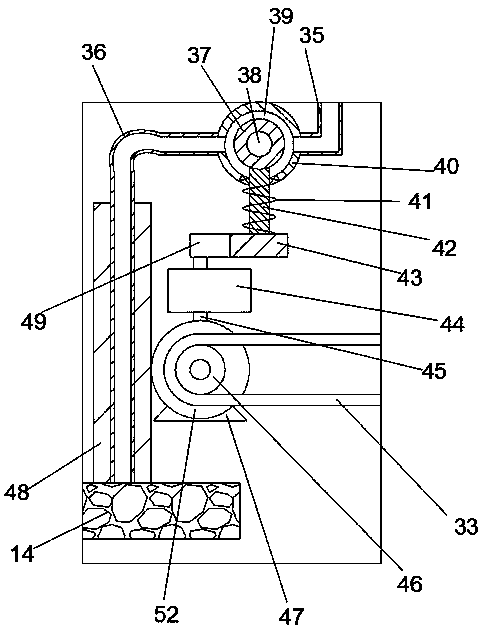

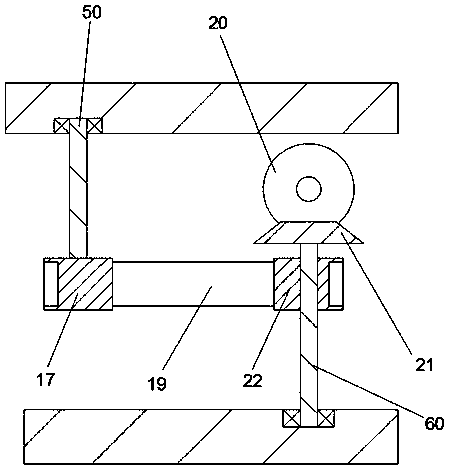

[0016] Combine below Figure 1-4 The present invention is described in detail, and for convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0017] refer to Figure 1-4 , according to an embodiment of the present invention, a carton printing device that can automatically add ink at regular intervals includes a housing 11, a working chamber 12 is provided in the housing 11, and the rear inner wall of the working chamber 12 is provided with a The transmission assembly 901 for the printing carton to be transported to the right, the printing assembly 902 is provided on the inner wall of the rear side of the working chamber 12, and the printing assembly 902 includes a toothed hollow slide bar which is arranged on the inner wall of the rear side of the working chamber 12 and can slide up and down 48. The printing device 14 fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com