Telescopic spray-coating robot for spray-coating shell plating

A spraying robot, telescopic technology, applied in the field of wall-climbing robots, can solve problems such as single movement mode of the mechanical arm, inability to realize complex curved surface spraying operations on the hull surface, and inability of the mechanical arm to achieve multi-degree-of-freedom rotation, so as to ensure the quality of spraying Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

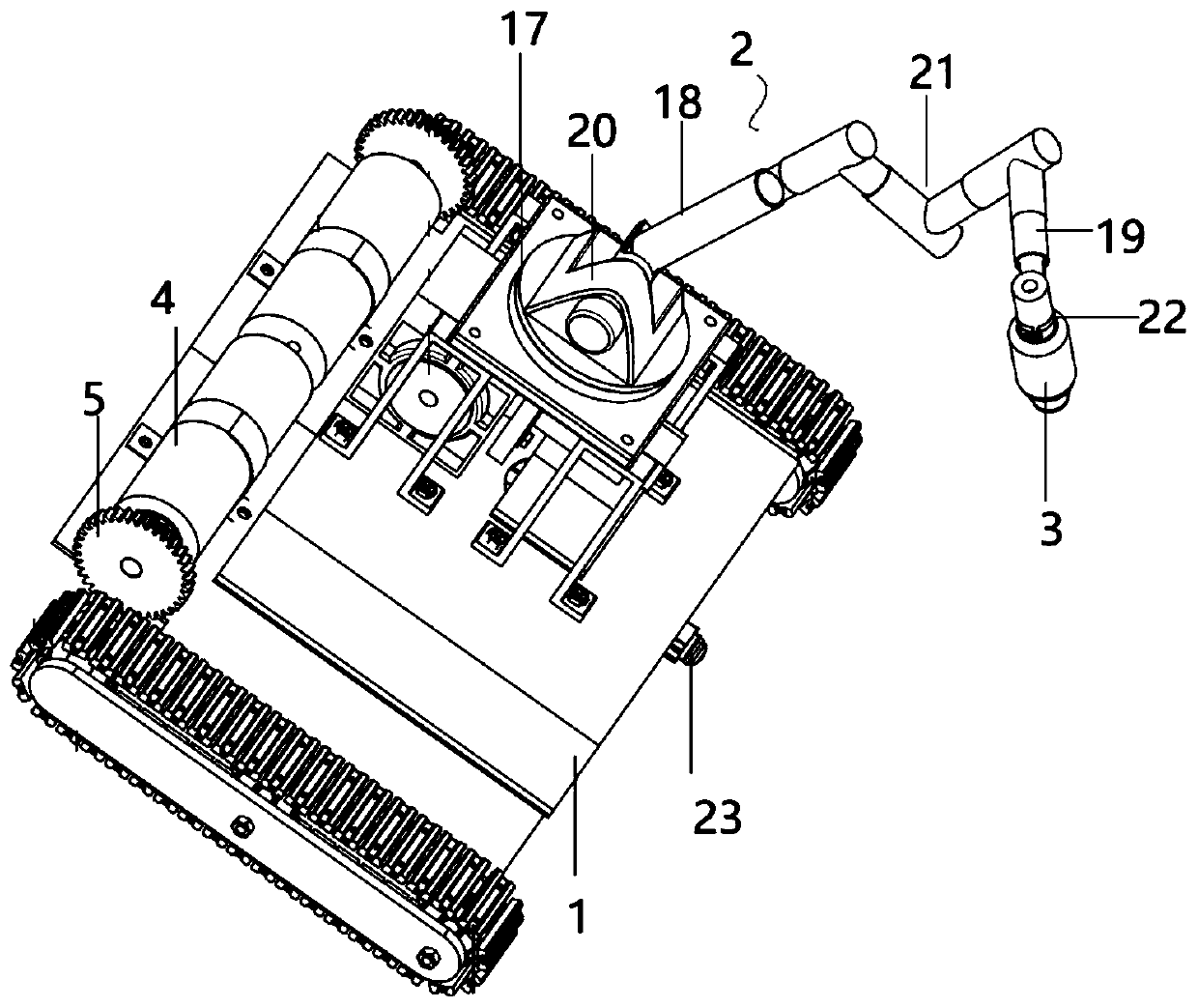

[0019] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

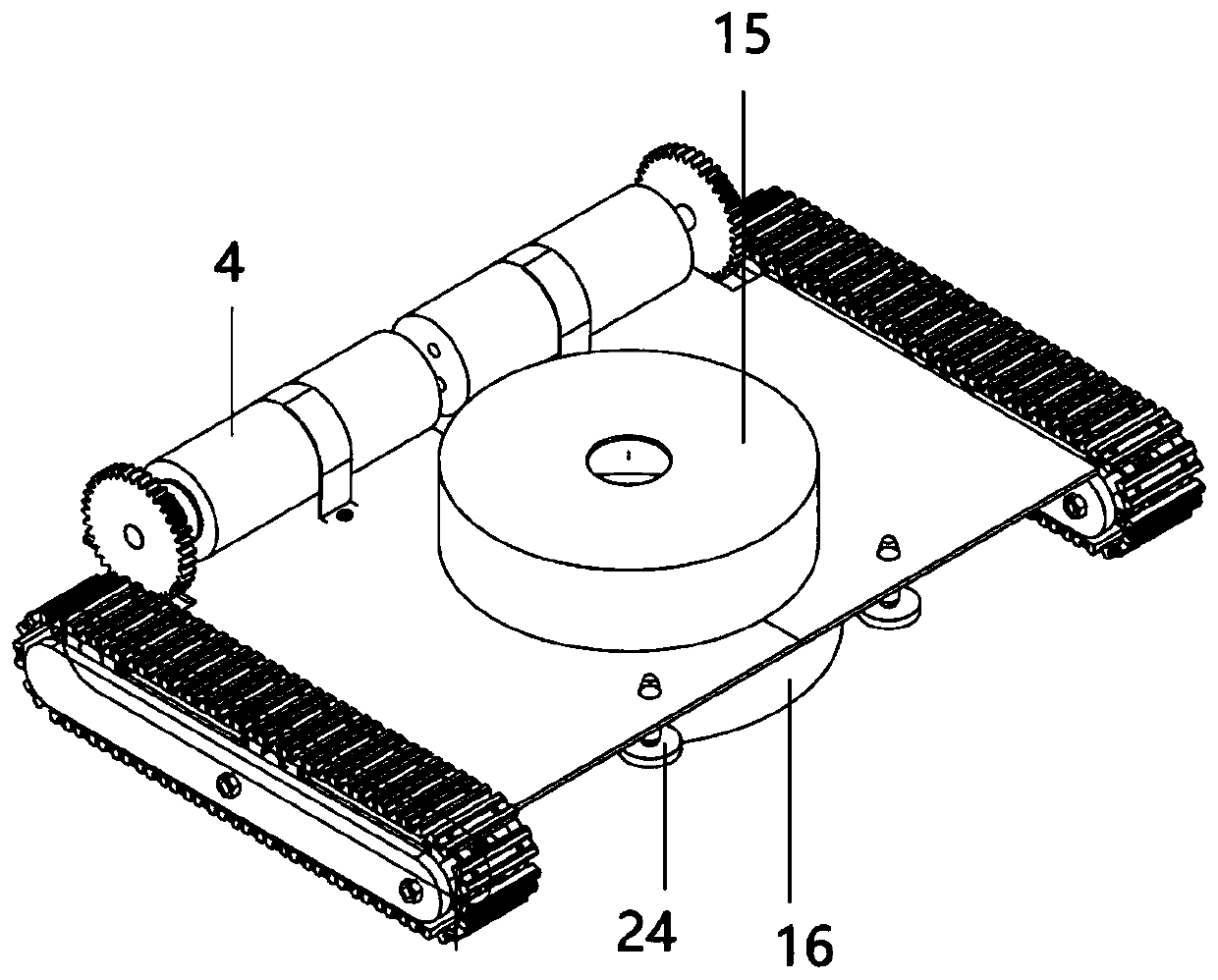

[0020] Such as figure 1 The shown telescopic spraying robot for coating the outer plate of a ship includes a frame 1 and a mobile module set on the frame 1, an adsorption module, a retractable mechanical arm 2, a spray gun 3 and a detection and feedback module; the spray gun 3 adopts Rotary cup electrostatic spray gun.

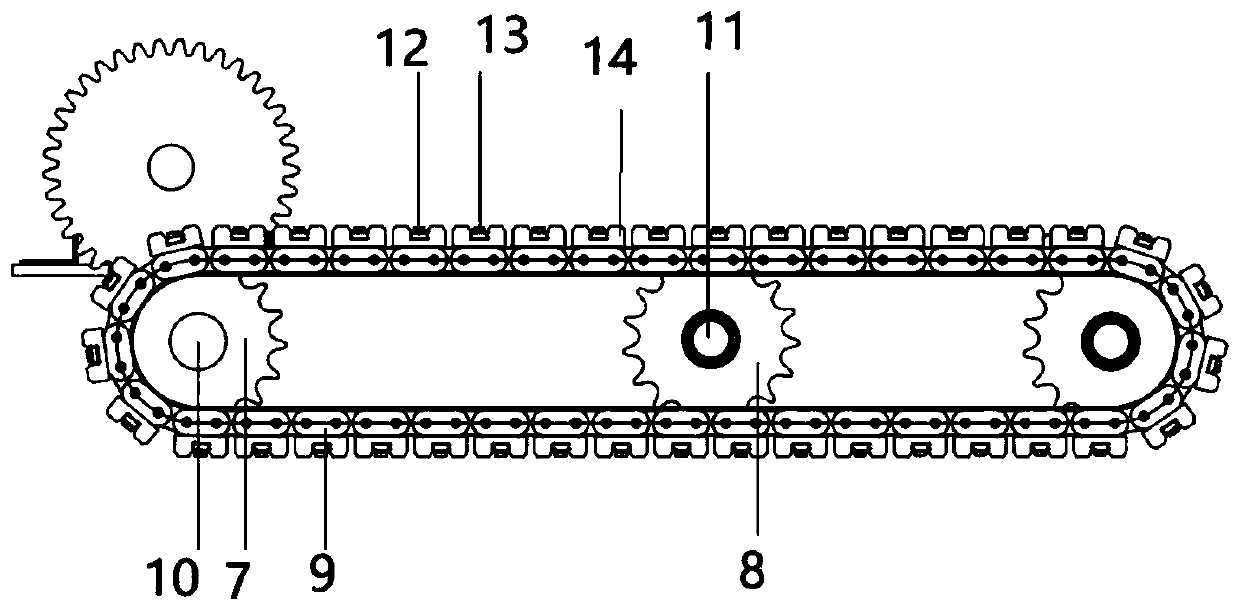

[0021] The mobile module includes a track assembly symmetrically arranged on both sides of the frame 1 and an air motor 4 that drives the track assembly, and the steering of the robot is controlled by controlling the speed difference of the air motor 4;

[0022] The adsorption module includes a permanent magnetic adsorption unit arranged on the track assembly and a vacuum adsorption unit arranged in the middle of the frame 1;

[0023] The spray gun 3 is arranged on the frame 1 through the telescopic mechanic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com