Industrial robot big arm structure optimization method based on orthogonal test

An industrial robot and orthogonal test technology, applied in constraint-based CAD, design optimization/simulation, instruments, etc., to achieve obvious lightweight, obvious effect, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

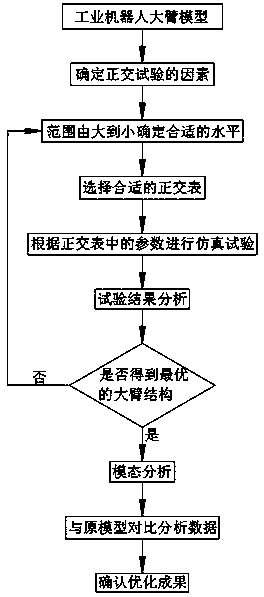

[0037] This embodiment is based on the structural optimization method of the industrial robot arm of orthogonal test, such as figure 1 As shown, the optimization method includes the following steps:

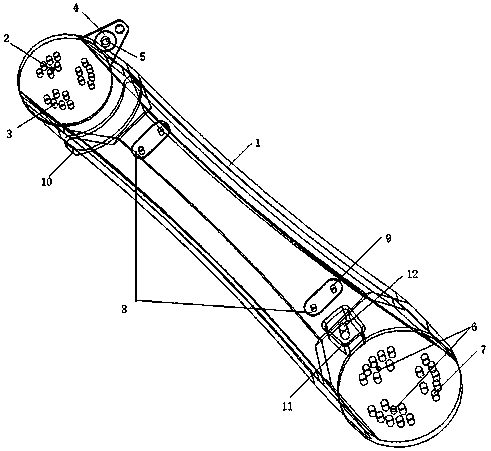

[0038] Step 1: If figure 2 As shown, the industrial robot arm is selected as the optimization object, and the industrial robot arm is selected as figure 2 As shown, the arm body 1 including a hollow structure has a positioning pin hole 2 and 18 through holes 3 on the front assembly surface of the arm body 1, and a cylindrical positioning boss 4 is provided on the side of the front assembly surface of the arm body 1, There is a through hole 5 in the center of the boss 4; there are 2 positioning pin holes 6 of different sizes and 21 through holes 7 on the end assembly surface of the arm body, and there are 2 bosses 8 on the front of the arm body 1, each boss There are two through holes 9 on the top of the 8, which are used for fixing the industrial robot lines and pipelines; on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com