Boiler blowdown recycling method and device

A boiler blowdown and boiler technology, applied in boiler cleaning devices, separation methods, chemical instruments and methods, etc., can solve problems such as waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

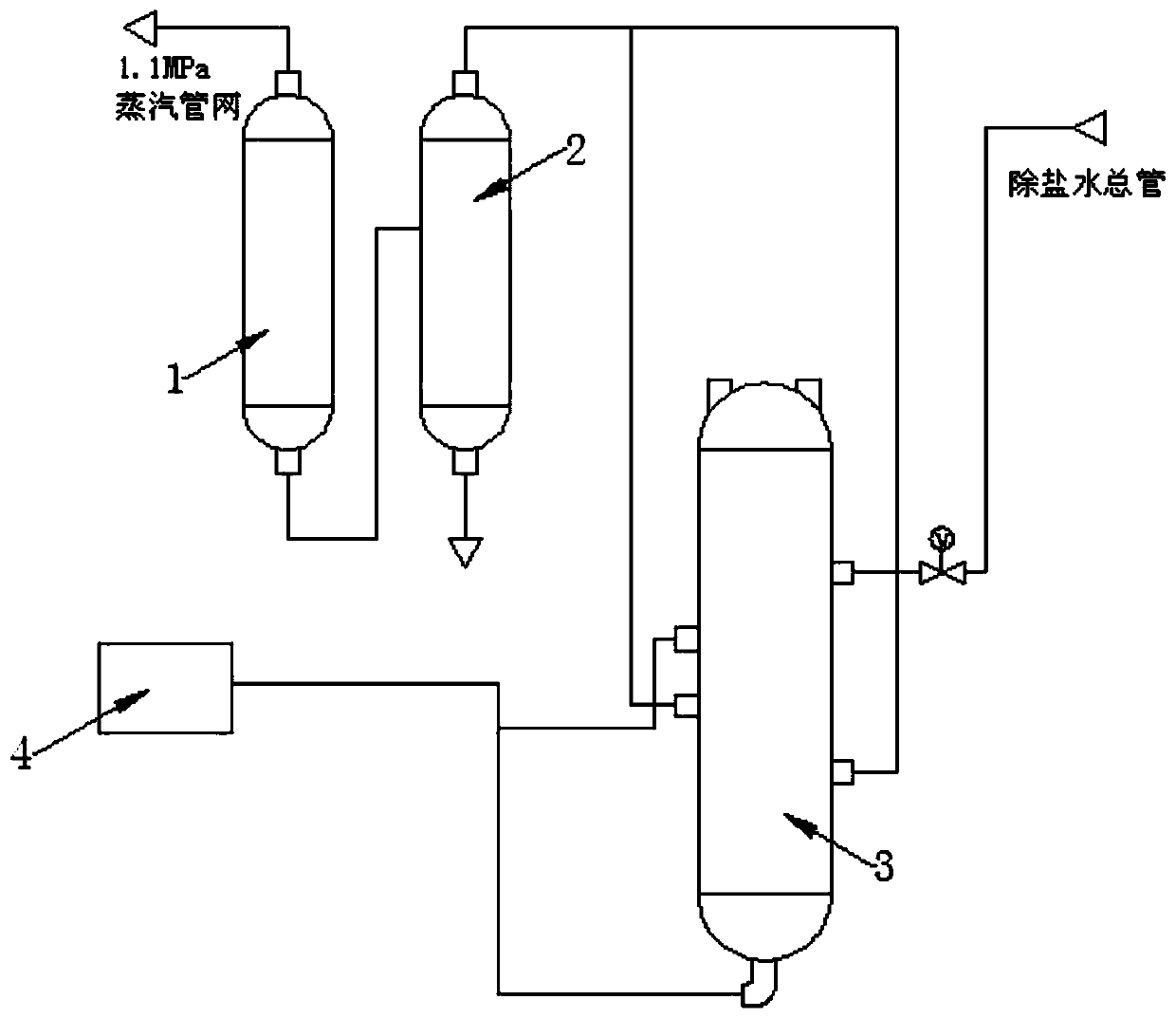

[0040] Such as figure 1 Shown, a kind of boiler sewage recycling method, described method comprises the following steps:

[0041] S1: The continuous drainage of the boiler enters the continuous expansion vessel 1 for flash evaporation to obtain saturated steam and high-temperature water;

[0042] S2: The high-temperature water obtained in S1 is discharged into the fixed discharge tank 2, and flashed together with the system drainage discharged into the fixed discharge tank 2 to obtain exhausted steam and water;

[0043] S3: The exhaust steam enters the absorption tower 3 to be liquefied to obtain high-temperature water;

[0044] S4: The high-temperature water obtained in S3 enters the gas-water separation device, and the non-condensable gas in the water is separated and discharged;

[0045] S5: The high-temperature water after the non-condensable gas is separated in S4 enters the deaerator 4 .

Embodiment 2

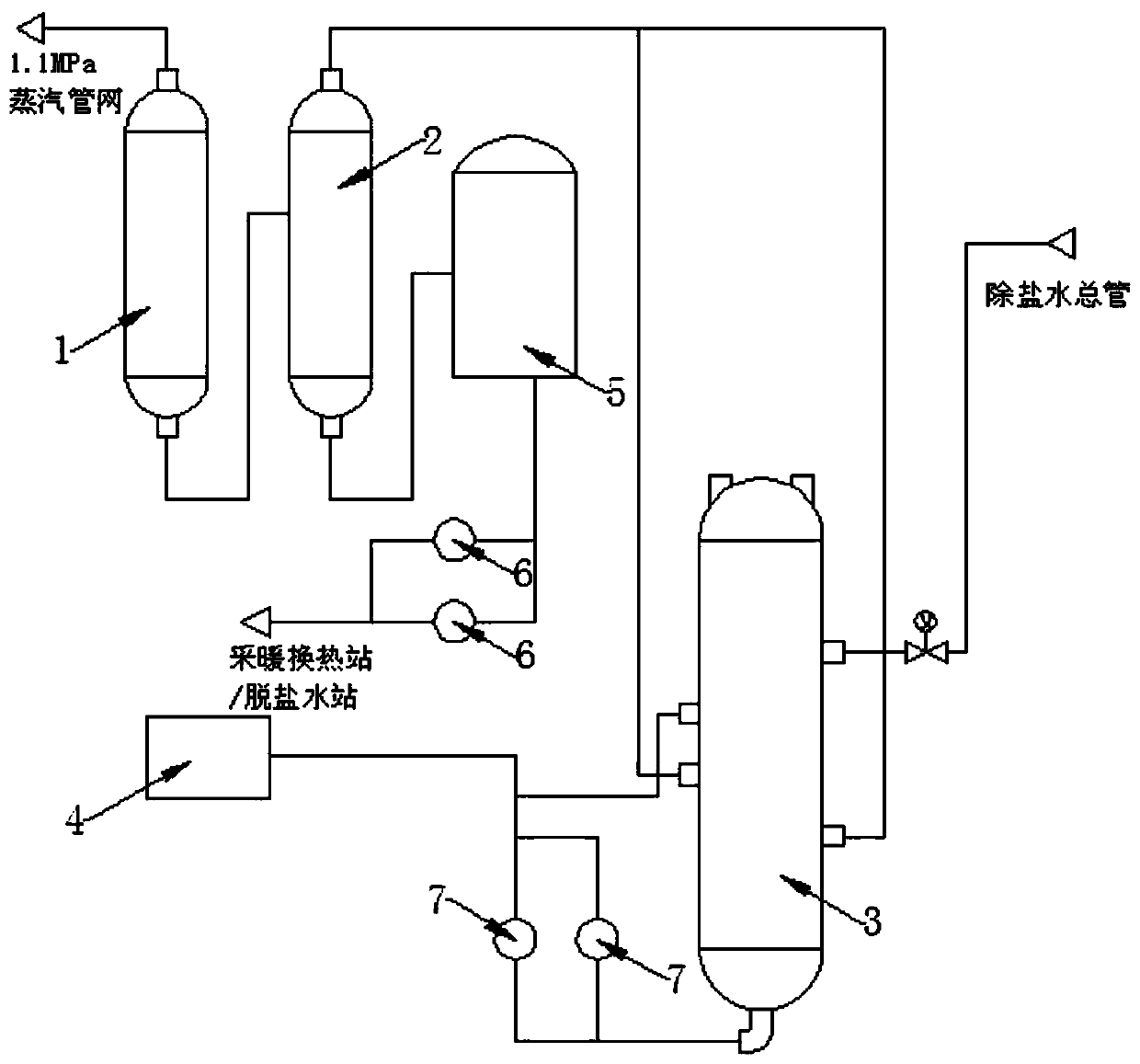

[0047] Such as figure 2 Shown, a kind of boiler sewage recycling method, described method comprises the following steps:

[0048] S1: The continuous drainage of the boiler enters the continuous expansion vessel 1 for flash evaporation to obtain saturated steam and high-temperature water, and the saturated steam is merged into the 1.1MPa pipe network for heating in chemical production;

[0049] S2: The high-temperature water obtained in S1 is discharged into the fixed row tank 2, and flashed together with the system drainage discharged into the fixed row tank 2 to obtain exhaust steam and water, and the water is discharged into the drain tank 5, and the water in the drain tank 5 It is discharged through the drain pump 6, used as hot water in the heating water system of the heat exchange station during the heating period, and part of the hot water is used as replenishment for the raw water system of the desalinated water station when it is in excess; it is used as replenishment f...

Embodiment 3

[0055] Such as figure 1 As shown, a boiler blowdown recovery and utilization device, said device includes a continuous expansion vessel 1, a fixed discharge tank 2, an absorption tower 3 and a deaerator 4, and the continuous expansion vessel 1 is provided with a continuous drainage inlet and a steam outlet and a high-temperature water outlet, the fixed discharge tank 2 is provided with a high-temperature water inlet, a exhaust steam outlet and a drain outlet, and the absorption tower 3 is provided with a exhaust steam inlet, a high-temperature water outlet and a non-condensable gas outlet, and the absorption tower 3 interior An ejector and a gas-water separation device are provided, and the deaerator 4 includes a high-temperature water inlet, a high-temperature water outlet and an oxygen outlet;

[0056] The high-temperature water outlet of the continuous expansion vessel 1 is connected with the high-temperature water inlet of the fixed row tank 2, the exhaust steam outlet of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com