Triaxial double-power jaw crusher

A jaw crusher, dual-power technology, applied in grain processing, etc., can solve the problems of poor strength, no crushing, increased cracks, etc., and achieve the effect of simplifying the toggle plate mechanism and the spring rod mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

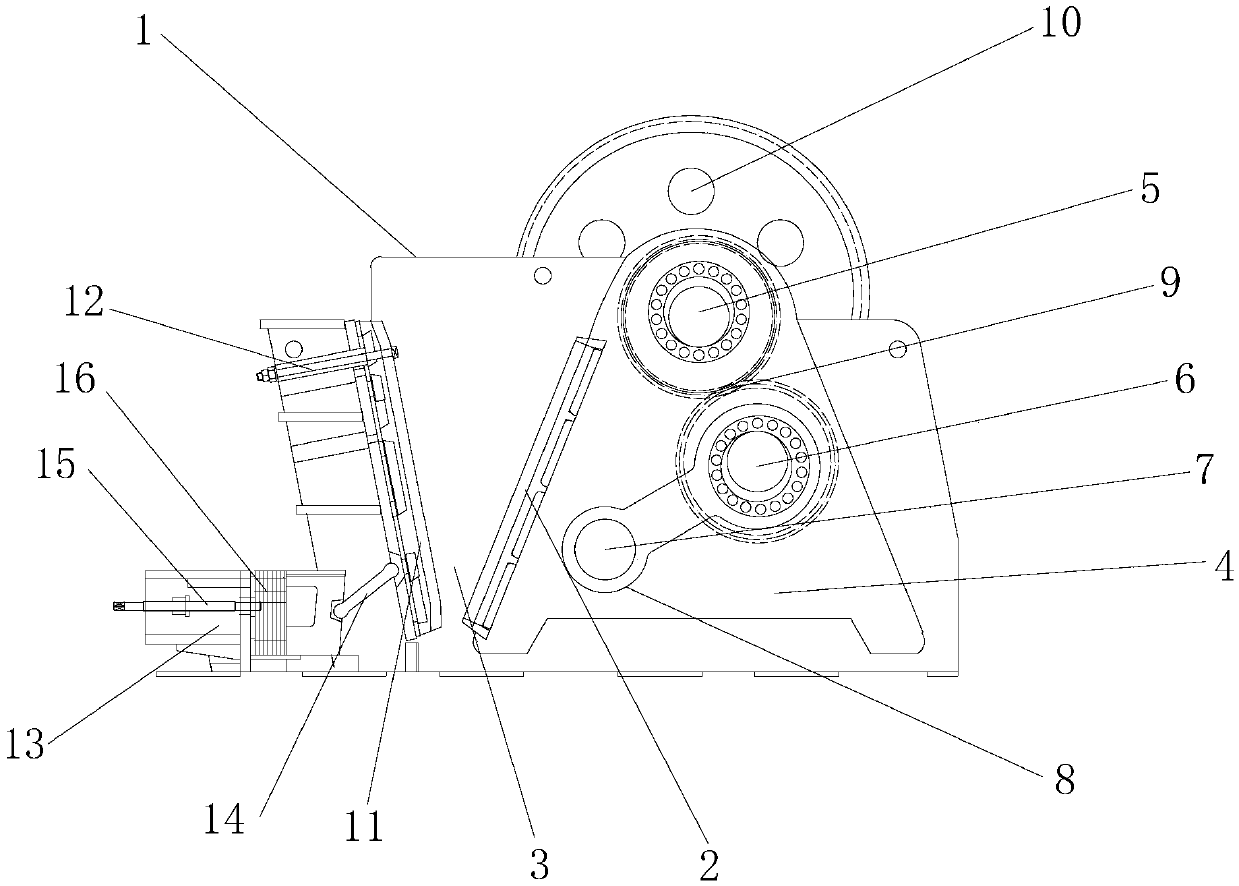

[0033] refer to figure 1 As shown, a three-axis dual-power jaw crusher includes a frame 1 and a movable jaw assembly. The movable jaw assembly is fixedly connected with a movable jaw plate 2 that is movable relative to the fixed jaw assembly. The frame 1 is provided with Cooperating with the fixed jaw plate 11 of the movable jaw plate 2, the fixed jaw plate 11 and the movable jaw plate 2 form a crushing and discharging cavity 3 with a wide top and a narrow bottom. The movable jaw assembly includes the movable jaw 4, the first eccentric shaft 5, the second The eccentric shaft 6 and the concentric shaft 7, the first eccentric shaft 5 and the second eccentric shaft 6 have the same structure. Above the eccentric shaft 6 and the concentric shaft 7, the frame 1 is provided with a driving device for driving the rotation of the first eccentric shaft 5 and the second eccentric shaft 6, and the first eccentric shaft 5 and the second eccentric shaft 6 are respectively connected with a fi...

Embodiment 2

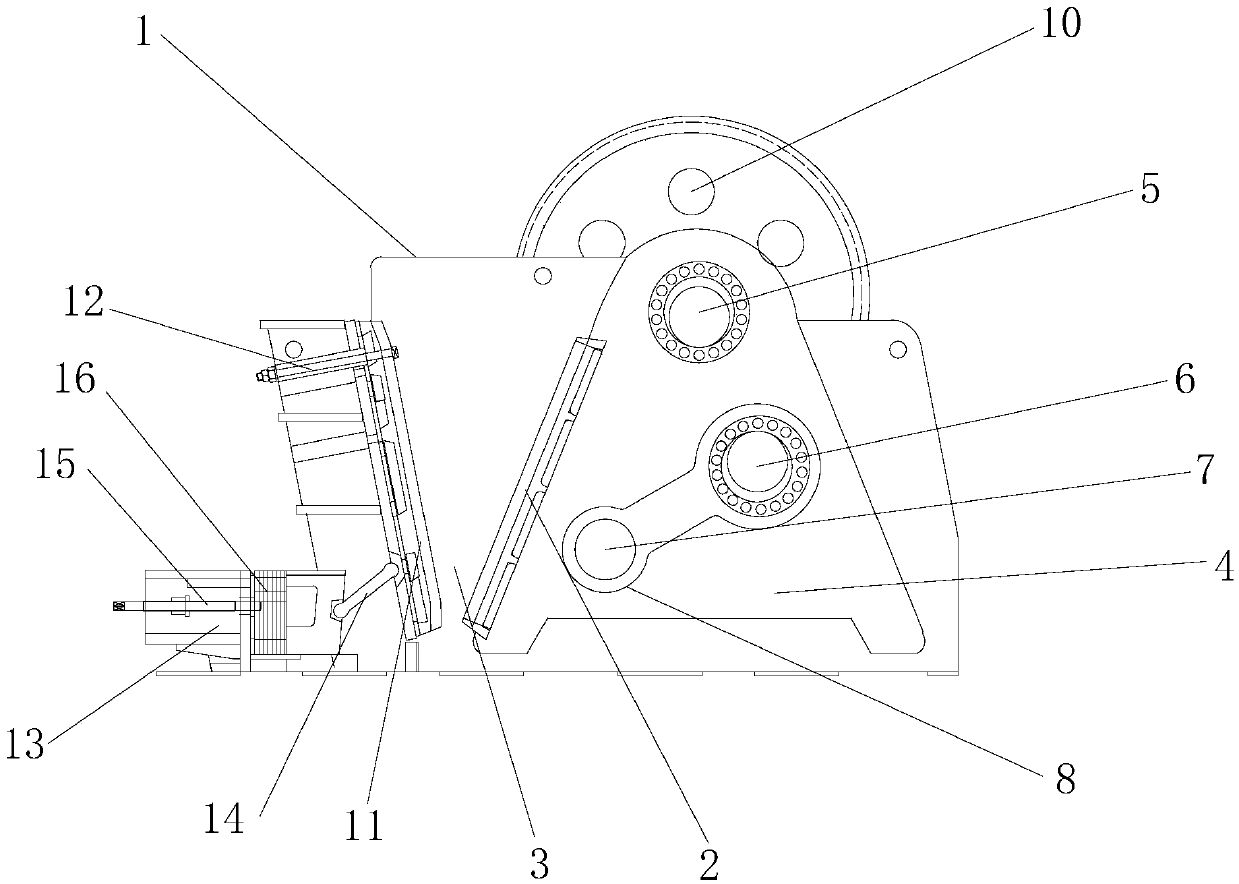

[0041] refer to figure 2 As shown, a three-axis dual-power jaw crusher includes a frame 1 and a movable jaw assembly. The movable jaw assembly is fixedly connected with a movable jaw plate 2 that is movable relative to the fixed jaw assembly. The frame 1 is provided with Cooperating with the fixed jaw plate 11 of the movable jaw plate 2, the fixed jaw plate 11 and the movable jaw plate 2 form a crushing and discharging cavity 3 with a wide top and a narrow bottom. The movable jaw assembly includes the movable jaw 4, the first eccentric shaft 5, the second The eccentric shaft 6 and the concentric shaft 7, the first eccentric shaft 5 and the second eccentric shaft 6 have the same structure. Above the eccentric shaft 6 and the concentric shaft 7, the frame 1 is provided with a driving device for driving the rotation of the first eccentric shaft 5 and the second eccentric shaft 6, and the first eccentric shaft 5 and the second eccentric shaft 6 are respectively connected with a f...

Embodiment 3

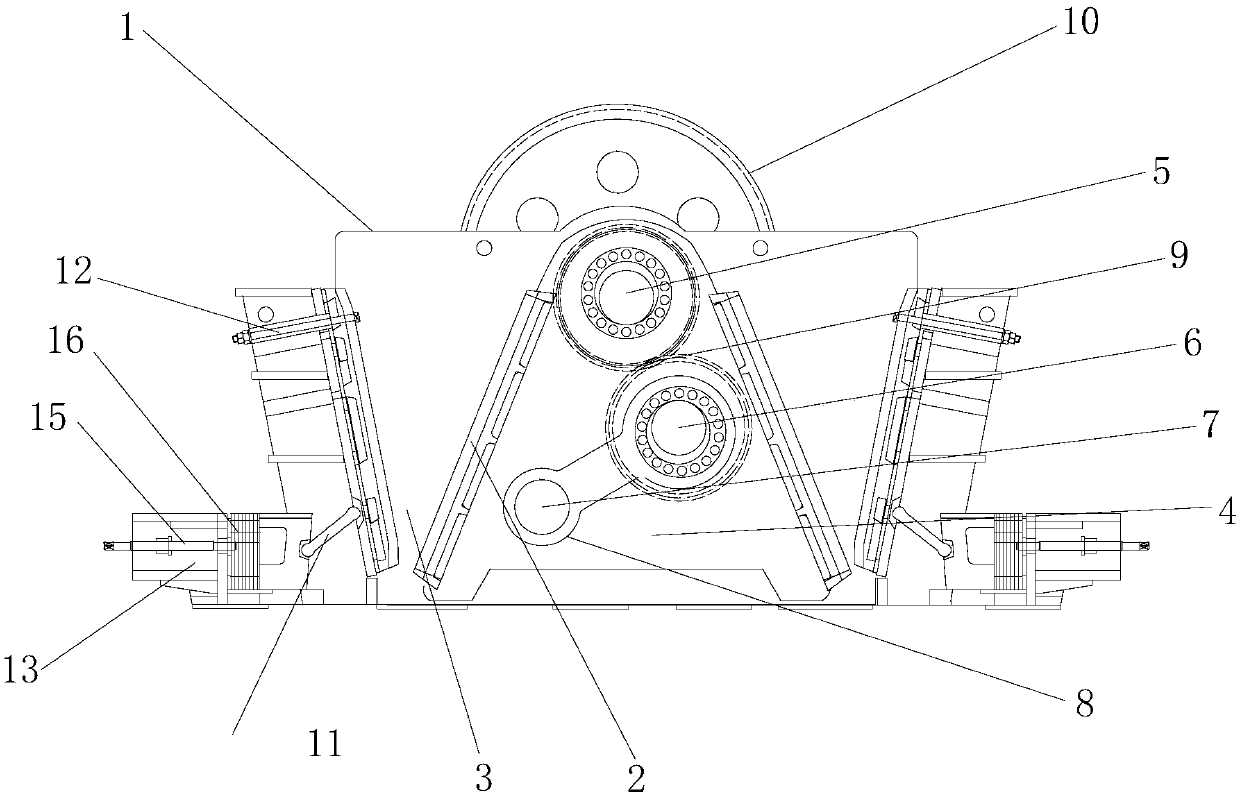

[0047] refer to image 3 As shown, a three-axis double-power jaw crusher, the movable jaw 4 is a symmetrical structure, the movable jaw plate 2 is arranged on both sides of the movable jaw assembly, and the fixed jaw plate matching the movable jaw plate 2 is arranged on the frame 1 11. The fixed jaw plate 11 is opposite to the movable jaw plate 2 to form two crushing and discharging chambers 3 with a wide top and a narrow bottom. The movable jaw assembly includes a movable jaw 4, a first eccentric shaft 5, a second eccentric shaft 6 and a concentric shaft 7 , the first eccentric shaft 5 and the second eccentric shaft 6 have the same structure, the first eccentric shaft 5 and the second eccentric shaft 6 are both rotatably arranged on the frame 1, and the first eccentric shaft 5 is located between the second eccentric shaft 6 and the concentric shaft 7 Above, the frame 1 is provided with a driving device that drives the rotation of the first eccentric shaft 5 and the second ecc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com