Insulating hanging rack and telescopic clamp for electrified connection and operation method

A hanger and fixture technology, which is applied in the direction of overhead lines/cable equipment, etc., can solve the problems of unsatisfactory bucket trucks, etc., and achieve the effect of reducing unreasonable insulation and shielding areas, reducing the probability of danger, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

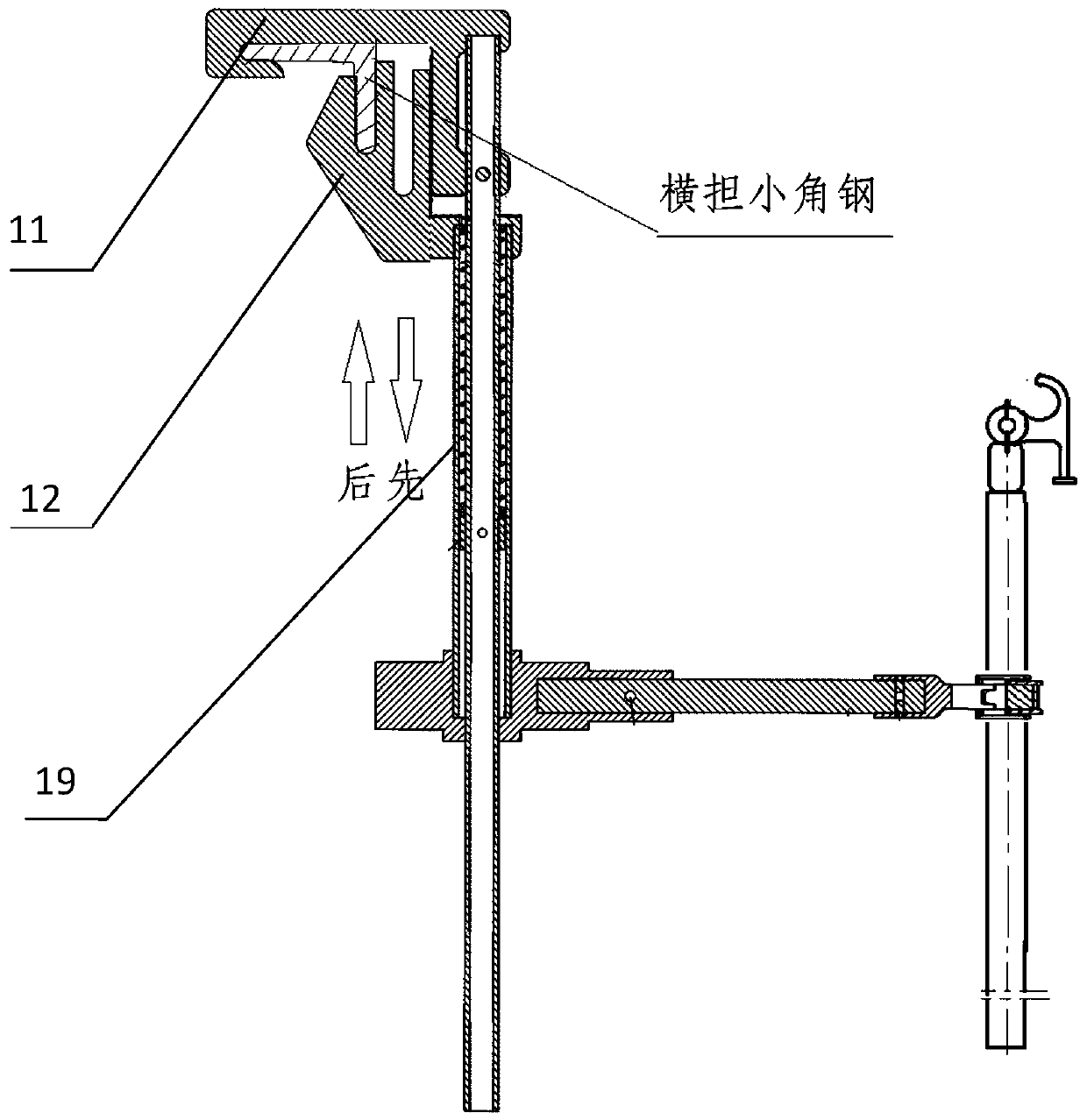

[0054] See figure 1 , is the outline structure diagram of the insulating hanger. An insulating hanger for live connection, comprising a top hanging base 11, an inner tube 110 connected to the top hanging base 11, an outer jacket 19 sleeved outside the inner tube 110, and an inner tube 110 arranged between the outer jacket 19. Spring ferrule 18 and stage clip 111, be located at the lower end holder 12 of one end of overcoat 19, be located at the hanging arm fixed frame 14 of the other end of overcoat 19, the hanging arm 13 that is connected with hanging arm fixing frame 14, be located at hanging arm 13 The fixed clip 15 at the end, the movable clip 16 installed on the fixed clip 15, the deadlock switch 17 installed on the movable clip 16.

[0055] The top hanging seat 11 of the present invention is L-shaped with a hook, which can easily hook the upper right-angled side of the cross-arm angle steel. The lower end clamping seat 12 is a special E-shaped, and the two grooves are r...

Embodiment 2

[0060] See Figure 5 , is the internal structure diagram of the telescopic fixture. A telescopic clamp for live connection, comprising a melon head 21, a hanger 28 arranged on the back of the melon head 21, an outer tube 22 arranged at the lower part of the melon head 21, and an outer pipe handle 25 arranged at the lower part of the outer pipe 22 , insert the inner tube 23 in the outer tube 22, be located at the stage clip ferrule 29 and the stage clip 210 between the outer tube 22 and the inner tube 23, the telescopic rod 27 installed at one end of the inner tube 23, pass the melon head 21 and The extrusion slider 26 installed on the end of the telescopic rod 27, the steel ball 212 located in the middle of the extrusion slider 26 and the telescopic rod, the inner tube stretching handle 24 located at the end of the inner tube 23, and the inner tube stretching handle 24 on the bolt 211.

[0061] A kind of telescopic clamp used for live connection of the present invention is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com