Two-in-one differential mode inductor

A differential mode inductance, two-in-one technology, used in transformer/inductor components, circuits, transformer/inductor coils/windings/connections, etc., can solve the problem of high production and assembly costs, high prices, and large product volumes. problem, to achieve the effect of compact structure, low price and small inductance attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

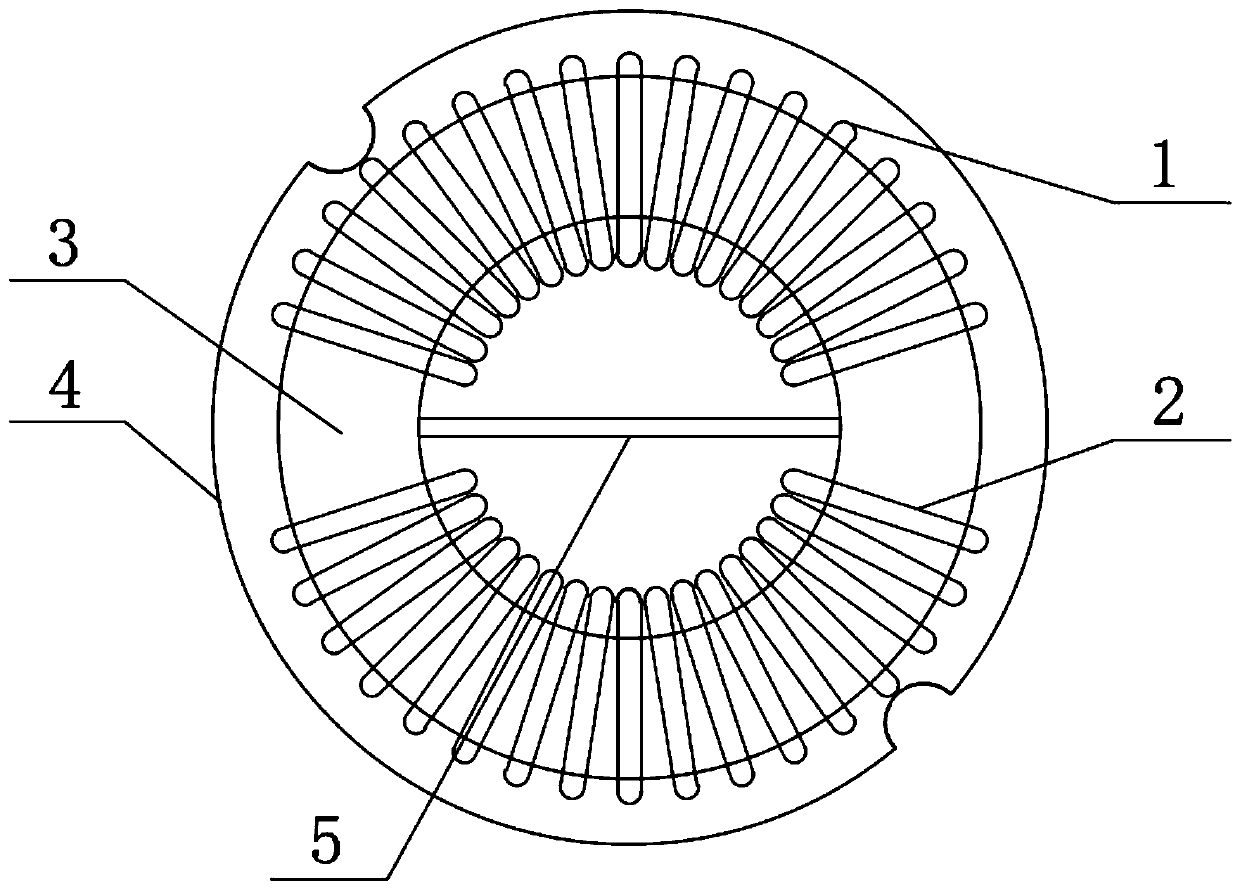

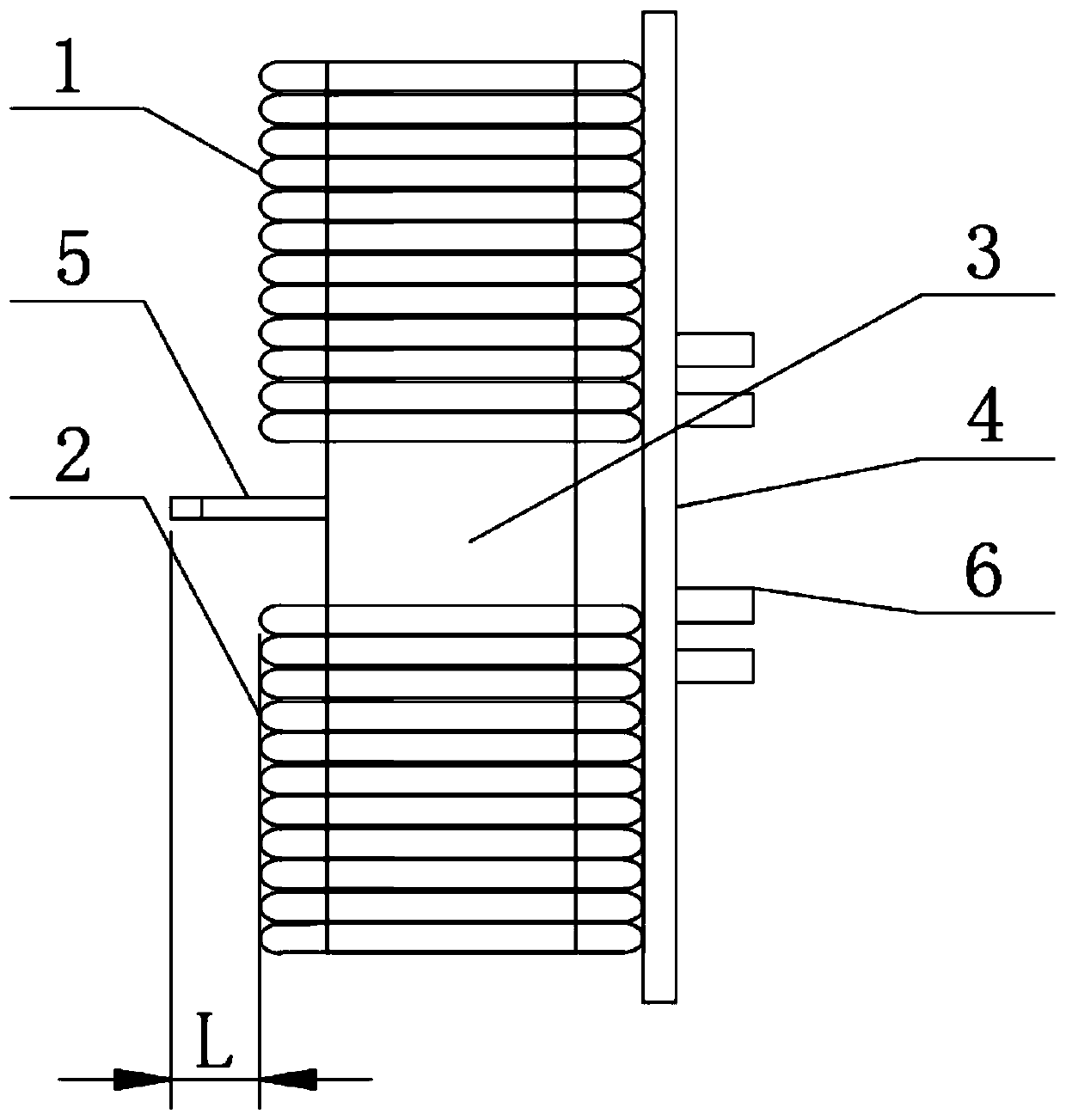

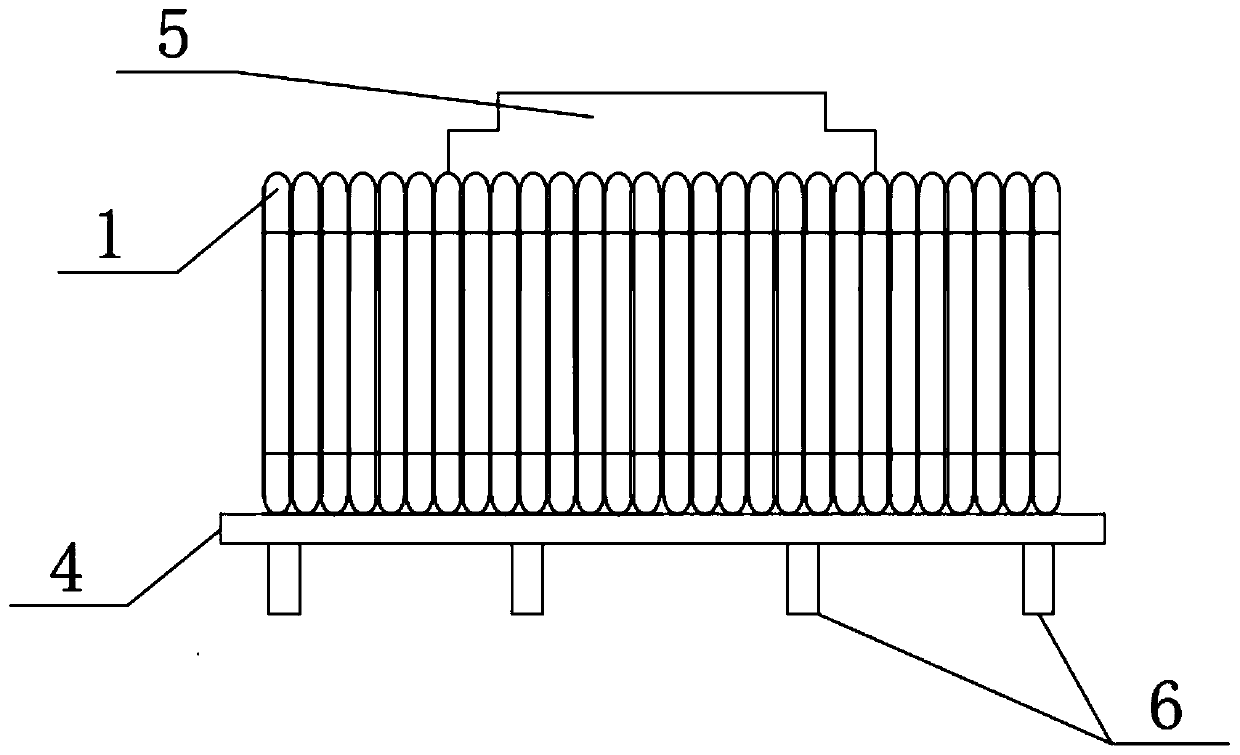

[0022] like Figure 1-Figure 4 As shown, the two-in-one differential mode inductor of this embodiment includes a ring magnetic core 3, a coil winding 1 and a coil winding 2 2 are wound at intervals on the ring magnetic core 3, and a ring is connected to the circumferential end surface of one end of the ring magnetic core 3. The oxygen baffle 5, the epoxy baffle 5 separates the coil winding one 1 and the coil winding two 2 along the radial direction of the annular magnetic core 3, and the circumferential end surface of the other end of the annular magnetic core 3 is fixedly connected to the base 4, and the base 4 is inserted There is inductor pin 6.

[0023] The coil winding one 1 and the coil winding two 2 are arranged symmetrically, and the epoxy baffle 5 is perpendicular to the circumferential end surface of the ring magnetic core 3 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com