Apparatus and method for detecting fatigue cracks in orthotropic panels

An orthotropic plate and fatigue crack technology, which can be used in measurement devices, analysis of solids using sonic/ultrasonic/infrasonic waves, and material analysis using sonic/ultrasonic/infrasonic waves. and other problems to achieve the effect of improving the detection efficiency and expanding the effective area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

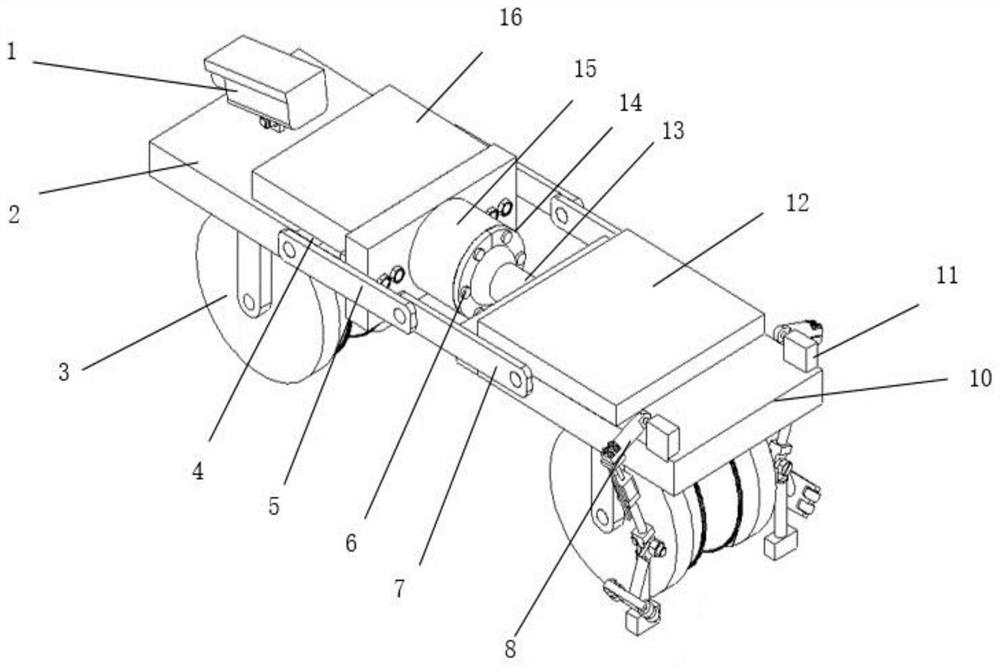

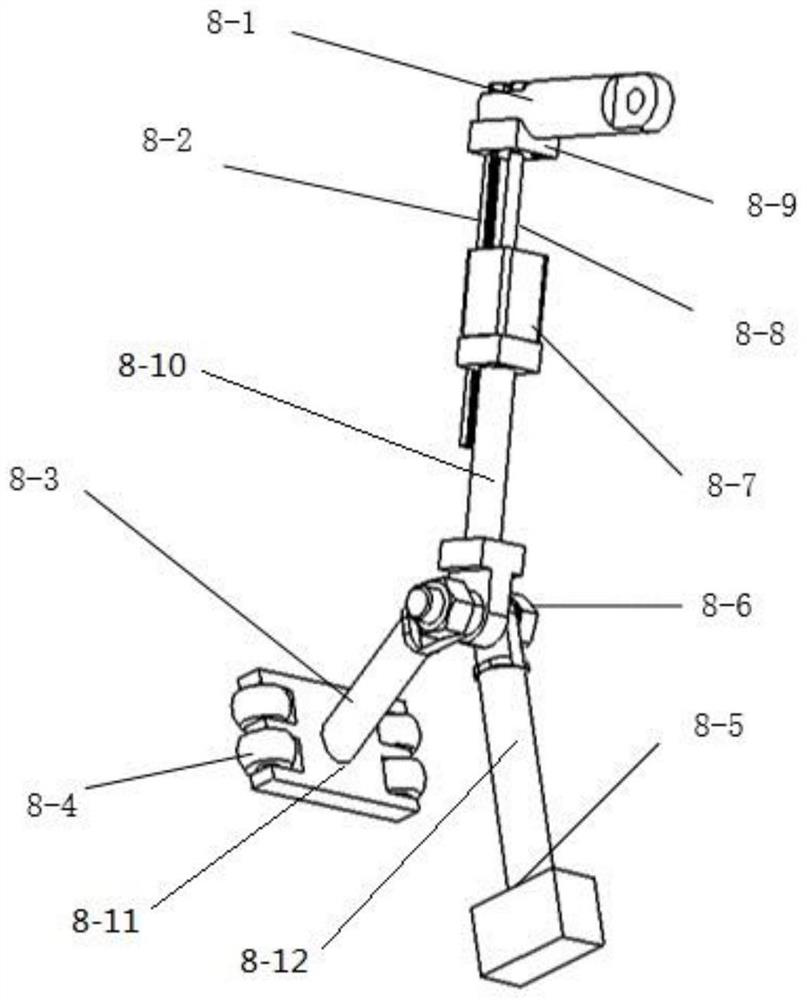

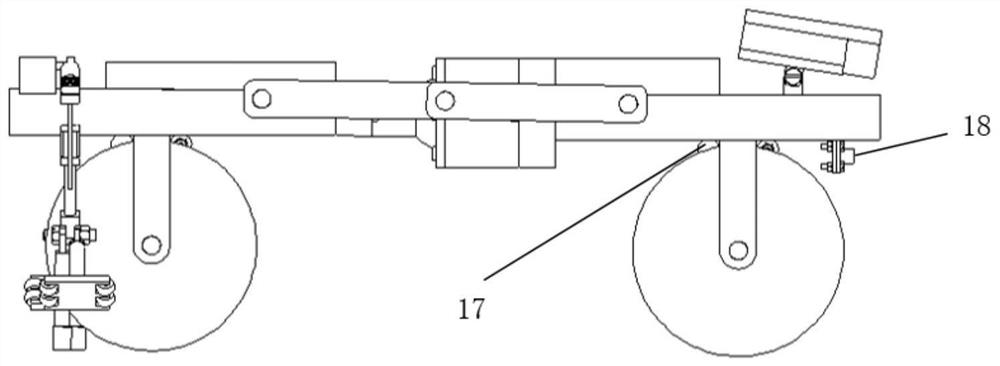

[0047] Such as Figure 1 to Figure 8 As shown, the device and method for using the present invention for fatigue crack detection of orthotropic panels include a vehicle body, the vehicle body includes a front 2 and a rear 10, the front 2 is hinged to the rear 10, and the front 2 is provided with an angle adjustment assembly, the angle adjustment assembly can adjust the size of the angle formed between the front 2 and the rear 10, the bottom of the front 2 and the rear 10 are provided with a first motor 17, the first motor 17 The output end is provided with a permanent magnet wheel 3; the tail 10 is also provided with a steering gear b11, the output end of the steering gear b11 is provided with a detection mechanism 8, and the detection mechanism 8 can rotate around the connection with the steering gear b11 , the detection mechanism 8 includes a connecting rod 8-1, a drive assembly, a connector 8-10, a limiter and a detection assembly, one end of the connecting rod 8-1 is conne...

Embodiment 2

[0049] On the basis of Embodiment 1, a camera 1 and a battery 16 are provided on the top of the vehicle head 2, and the camera 1 is connected to the battery 16 and the controller 12 respectively.

Embodiment 3

[0051] On the basis of Embodiment 1, a rotating shaft is provided at the center of the permanent magnet wheel 3, a first gear is provided on the rotating shaft, and the first gear and the permanent magnet wheel 3 are coaxial, and the output of the first motor 17 There is also a second gear meshed with the first gear on the end; there are two first motors 17 at the bottom of the front end 2 and the rear end 10, and the two first motors 17 are arranged in a misplaced position.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com