Variation microchannel cooling type surface flame low NOx gas device

A gas device and micro-channel technology, applied in burners, combustion methods, combustion types, etc., can solve problems such as unsatisfactory NOx emission, achieve elimination of local high temperature phenomenon, high heat transfer efficiency, and promote gas ignition and efficient combustion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

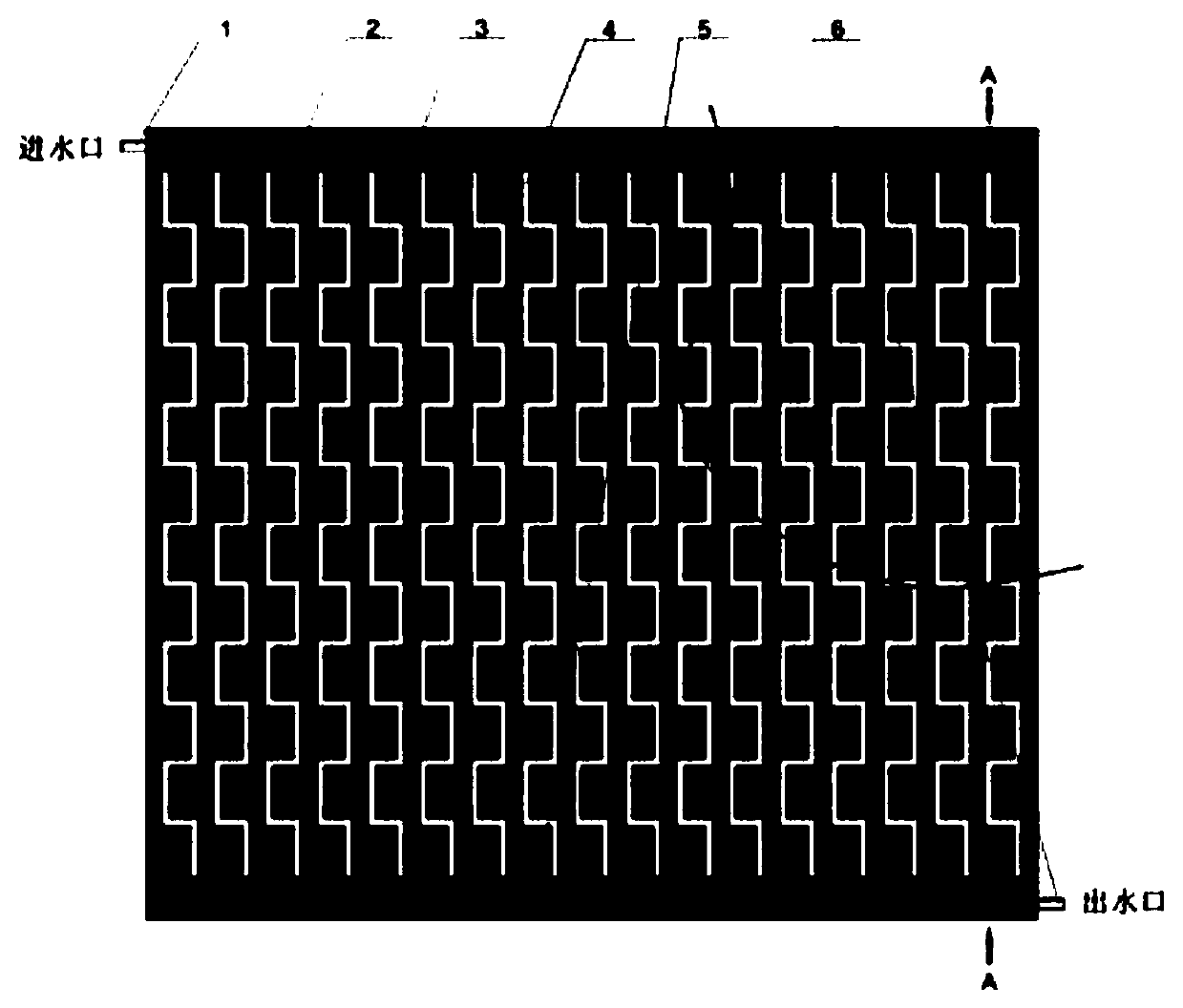

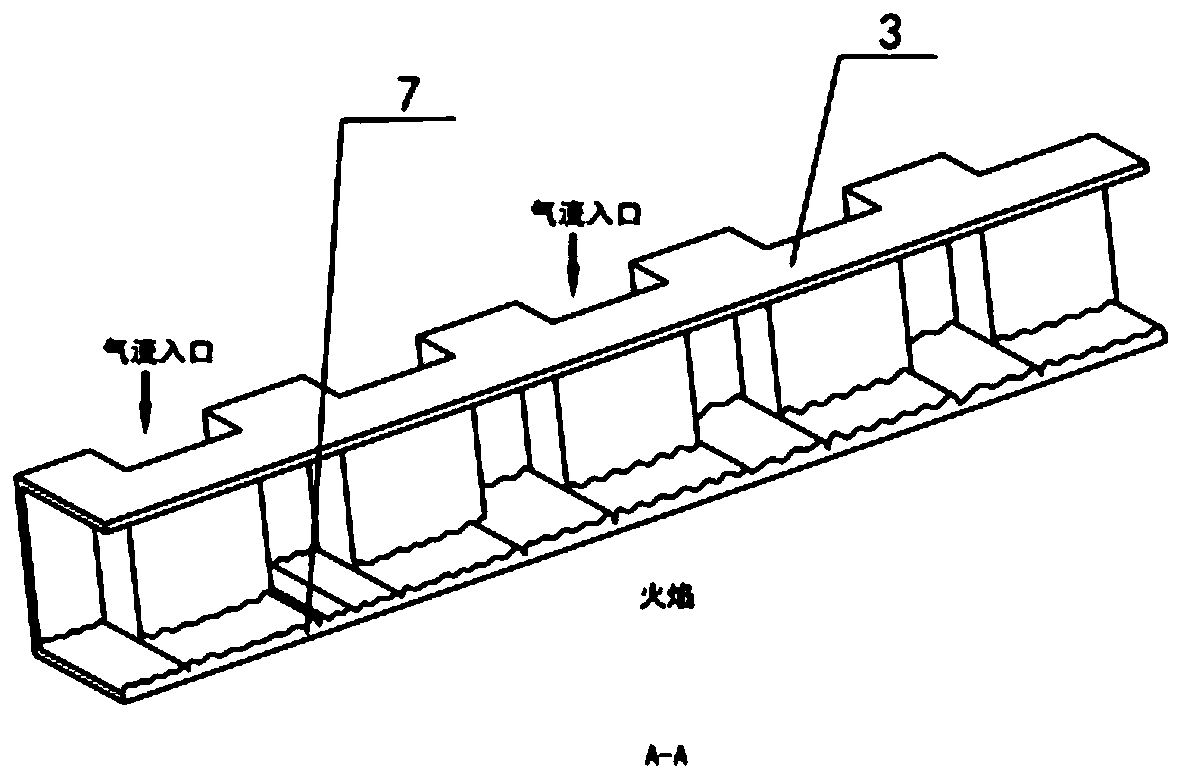

[0018] see figure 1 , the specific connection mode of the device of the present invention is as follows: multiple sets of dense parallel variable structure water cooling components 3 are connected in parallel to the upper header 2 and the lower header 5, and a variable airflow microchannel 4 is formed between two adjacent variable structure water cooling components 3 , the upper header 2 is provided with a water inlet 1, and the lower header 5 is provided with a water outlet 6. After the gas and air mixture flows through the dense and parallel variable airflow microchannels 4, a highly turbulent low-temperature surface combustion flame front is formed at its outlet and the surface of the water-cooling component 3 with a variable structure. The water-cooling assembly 3 with a variant structure has an alternate "concave-convex" structure, and the corresponding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com