Hydraulic torque converter device with combined vibration absorption function

A technology for torque converter and vibration damping, which is applied in transmission devices, springs/shock absorbers, fluid transmission devices, etc., can solve the problems of inability to change vibration and difficult to reduce flywheel vibration, and achieves strong usability, The effect of reducing torsional vibration and smooth transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

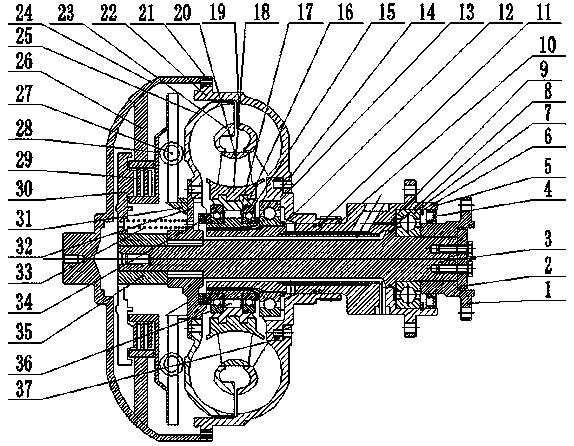

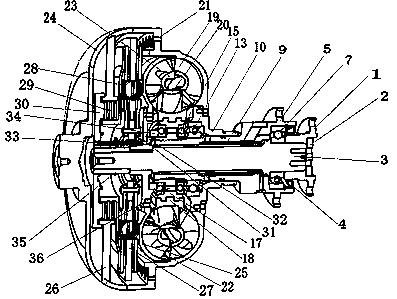

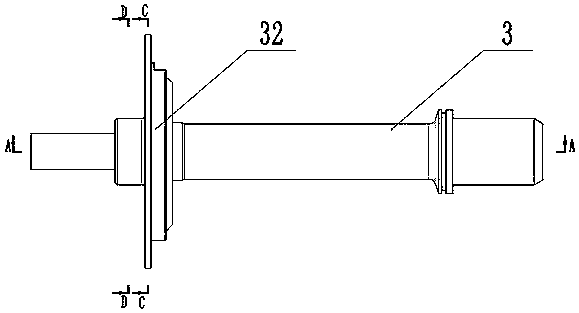

[0040] See Figure 1 to Figure 9 As shown, a hydraulic torque converter device with comprehensive damping effect includes a right cover plate 1, a pressure plate 2, a turbine output shaft 3, a sealing ring 4, a flange plate 5, a right bearing 7, a turbine output Shaft sleeve 9, pump wheel bearing support seat 10, pump wheel bearing 13, guide wheel bearing 15, guide wheel support seat 17, guide wheel hub 18, pump wheel inner ring 19, guide wheel inner ring 20, rubber gear 21, Pump wheel housing 22, turbine inner ring 23, pump wheel cover 24, turbine housing 25, support plate 26, torsion shock absorber 27, clutch driven disc 28, clutch driving disc 29, piston 30, turbine flange 31, turbine hub 32. Return spring 33, left positioning short sleeve 34 of the guide wheel support seat, short sleeve 35 of the turbine output shaft and bearing positioning sleeve 36 of the guide wheel support seat, the right side cover plate 1 is sleeved on the turbine output shaft 3. The pressure plate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com