A shallow tray cardboard transport device and cardboard transport method

The technology of a transportation device and a transportation method is applied in the field of the shallow pallet cardboard transportation device, which can solve the problems of large space, limited amount of cardboard to be transported, low cardboard suction efficiency, etc., and achieves the effect of reducing demand and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

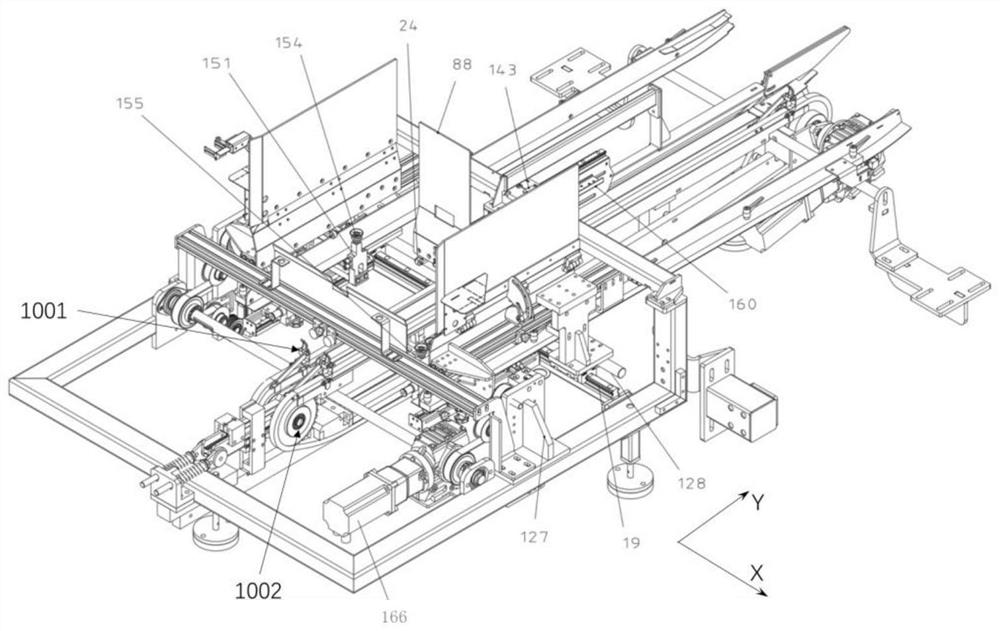

[0037] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

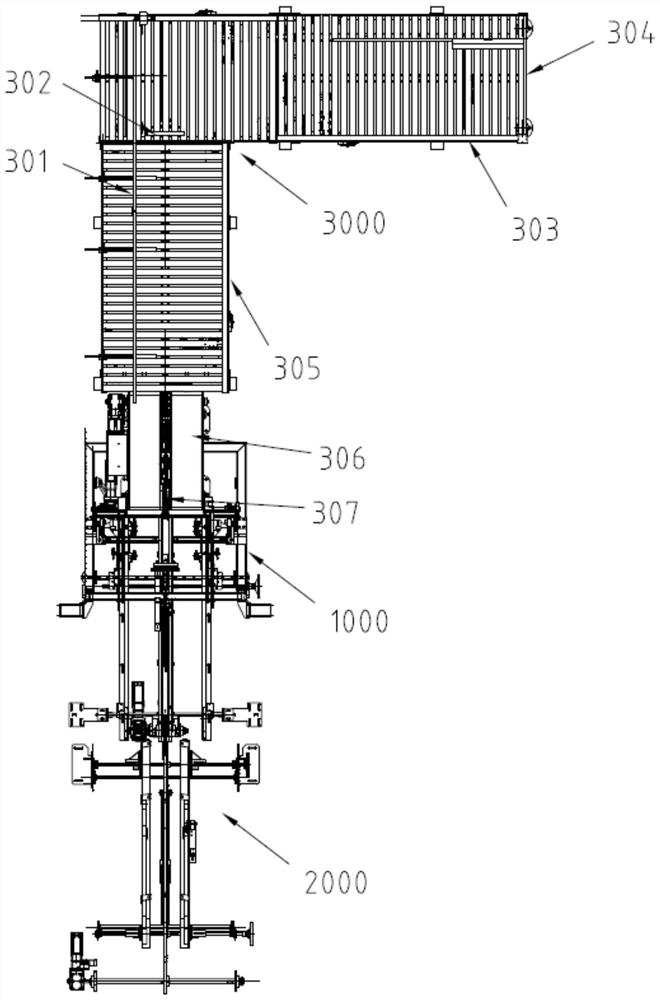

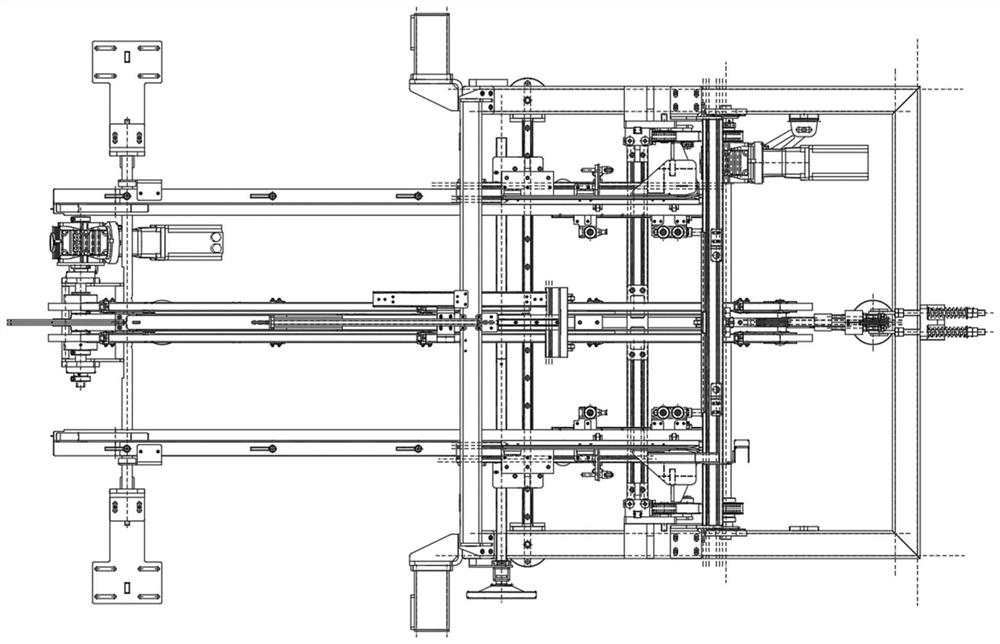

[0038] The shallow pallet cardboard conveying device provided by the present invention as a whole includes a cardboard conveying unit 3000 for stacking and transporting stacks of cardboards. The cardboards are placed in stacks on the first transport track 304 at the paper loading position 303 and are transported to the cardboard stop The board 301 is blocked behind, and then the cardboard push plate 302 moves downward from the upper side in the figure, and the cardboard is pushed onto the second transport track 305, and the stacked cardboard is transported to the transport platform 306 by the second transport track 305, because the transport platform 306 and the speed difference of the second conveying track 305, the stacked cardboards are separated one by one. The paper feeding push plate 307 moves downward from the upper side through the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com