Mixed line screw locking method

A screw and locking technology, applied in the field of automatic control, can solve the problems of single, incompatibility with mixed-line production, etc., and achieve the effect of improving production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

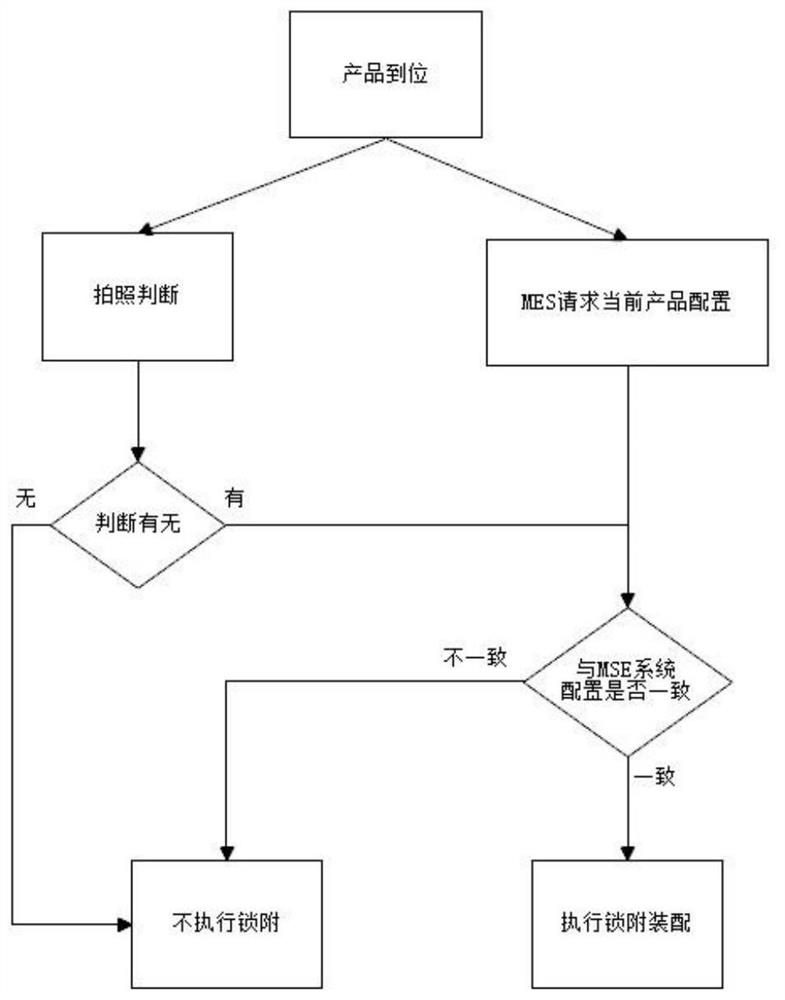

[0018] Such as figure 1 As shown, a screw locking method for mixed wires includes the following steps:

[0019] Step 1. When the product to be assembled arrives at the automatic screw locking machine, match it with the factory host computer through the MES system and request the configuration information of the current product;

[0020] Step 2. Take a visual photo of the product and upload the photo to the visual system;

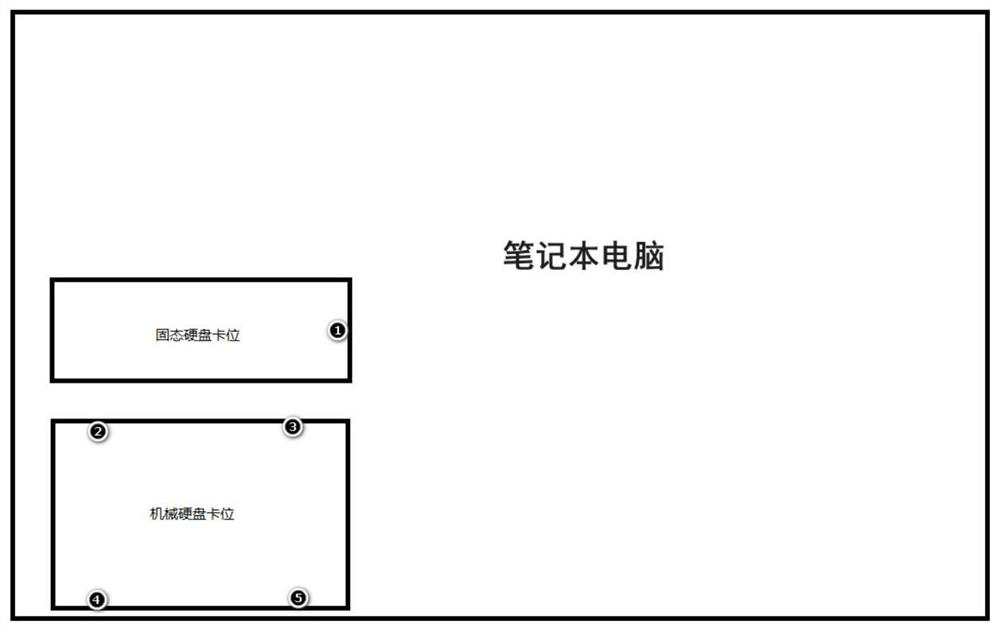

[0021] Step 3. Based on the photo comparison data received, the visual system judges whether there are parts that need to be assembled on the product and whether the parts are installed in place, and judges whether the parts meet the configuration requirements of the product under the order;

[0022] Step 4. If there are components that need to be assembled and installed in place, and also meet the configuration requirements of the product under the order, the automatic locking screw machine performs screw locking on the product components, otherwise, it do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com