Environment-friendly energy-saving cement additive reaction kettle

A cement additive, environmental protection and energy saving technology, applied in chemical/physical/physical-chemical stationary reactors, detailed information of chemical/physical/physical-chemical reactors, chemical/physical/physical-chemical processes, etc., to avoid potential safety hazards, Easy to replace and increase the effect of stirring resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

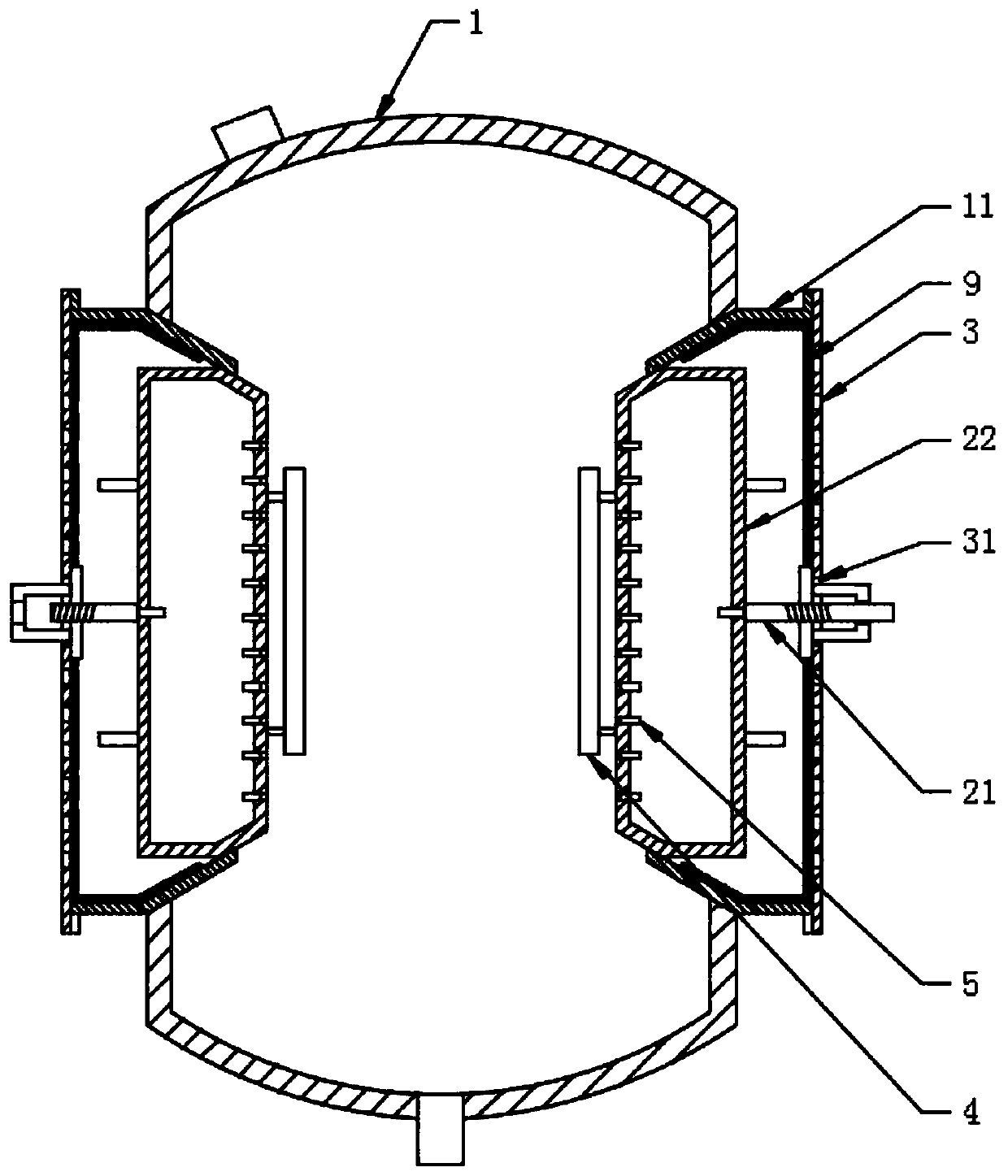

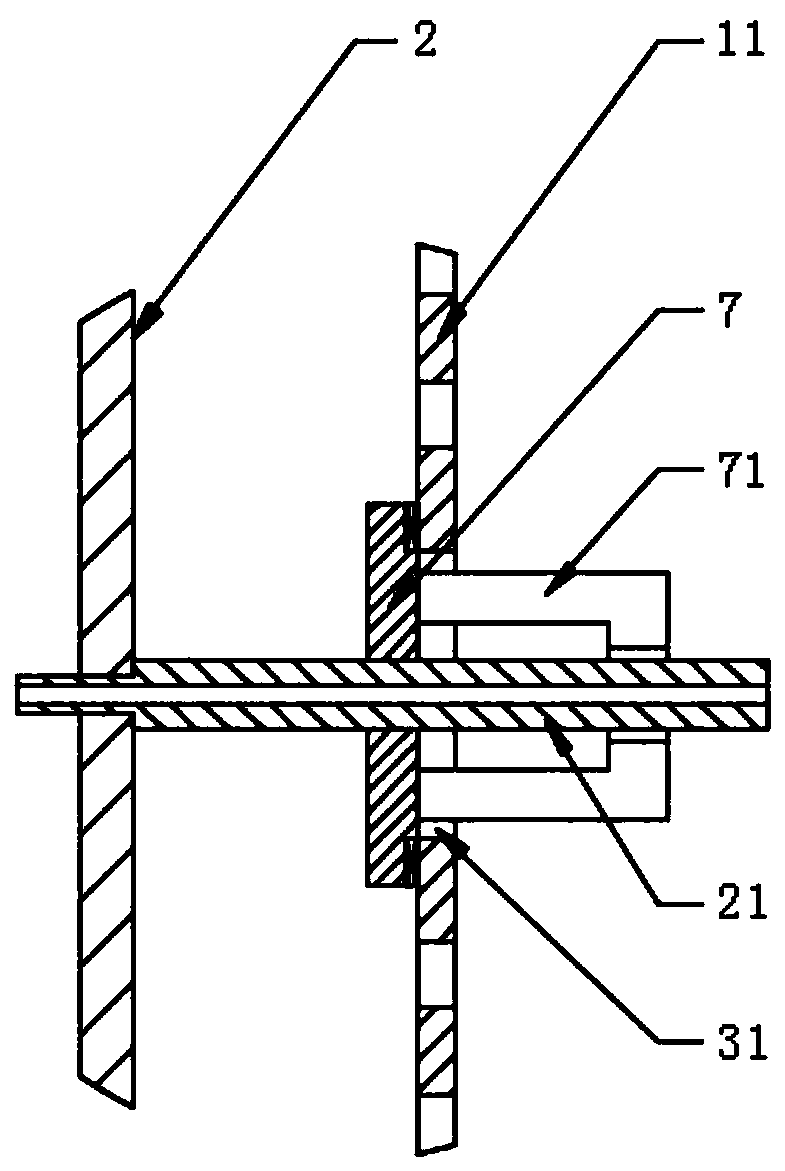

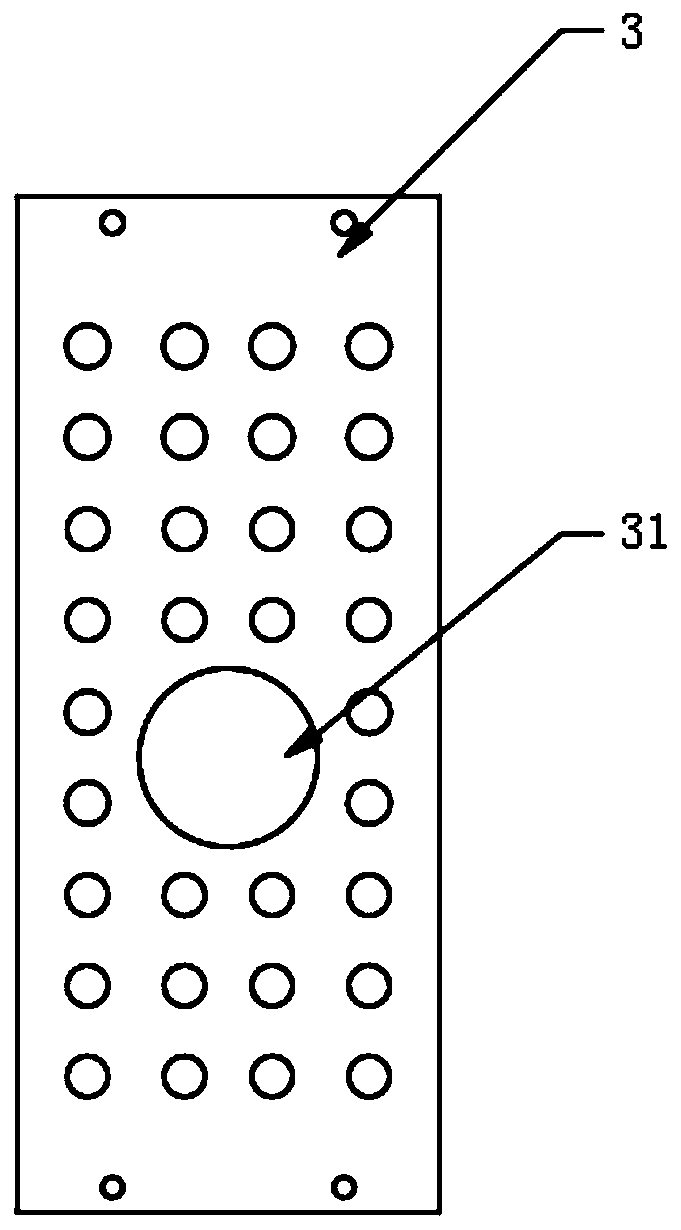

[0036] see Figure 1-5 , a cement additive reaction kettle based on environmental protection and energy saving, including a kettle body 1, the outer wall of the kettle body 1 is penetrated with a filter shell 11, the filter shell 11 is connected to the outside and the inner cavity of the kettle body 1, and a sealing shell is slidably connected inside the filter shell 11 2. After the sealing shell 2 is activated, the space between the filter shell 11 and the kettle body 1 is blocked. The inner surface wall of the filter shell 11 is covered with a filter layer 9. The filter layer includes a filter screen and a filter material located inside. The filter screen is a cover shape, the filter screen is fixed on the inner and outer walls of the filter shell 11 by bolts, and the filter material can be common activated carbon, which has high-quality filtering effect on harmful gases such as formaldehyde and naphthalene, and the filter shell 11 is located in the kettle body 1. The openin...

Embodiment 2

[0038] see figure 1 , the difference from Example 1 is that the tapered end of the sealing shell 2 extends into the kettle body 1 and is detachably connected with a baffle plate 4, and the baffle plate 4 is used to assist the stirring device in the kettle body to increase the stirring resistance. Removing the punching cover plate 3 can remove the entire sealing shell 2, so that the baffle plate 4 can be welded externally or connected by bolts, which is convenient for welding and replacement, and avoids the operation in the kettle body 1.

Embodiment 3

[0040] see figure 1 and Figure 4 , the difference from Example 1 is that the tapered end of the sealing shell 2 is provided with a one-way valve 5, one end of the one-way valve 5 is connected to the inner cavity of the sealing shell 2, and the other end is connected to a nozzle connected to the inner cavity of the kettle body 1 6. Since the kettle body usually has a high-temperature and high-pressure environment during the production process, the inside of the sealing shell 2 is in a high-temperature environment. When the inner cavity of the kettle needs to be cleaned, connect the liquid pipe 21 to an external water pipe or neutralize the solvent. The liquid enters the sealing shell 2 and is heated by the high-temperature sealing shell 2. At the same time, it is sprayed into the kettle body 1 through the nozzle 6. The high-temperature liquid can improve the cleaning efficiency of the kettle body 1 and has the effect of heat energy recovery and utilization.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap