Packaging equipment for nutrition powder processing

A technology of packaging equipment and nutrition powder, which is applied in the field of packaging equipment for nutrition powder processing, can solve the problems of excessive waste and easy blockage of packaging equipment, and achieve the effects of reducing waste, avoiding blockage, and improving packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

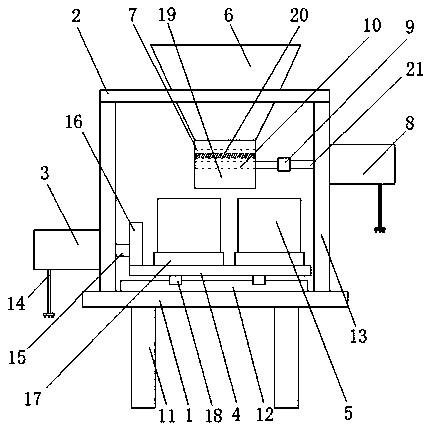

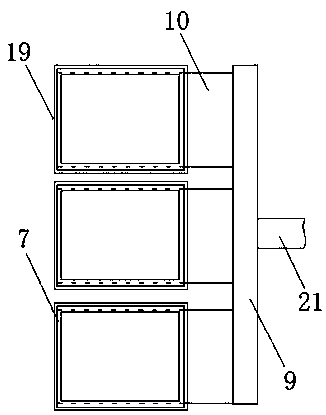

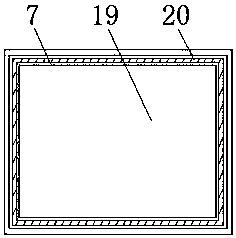

[0019] as attached Figure 1-3 As shown, a packaging equipment for nutritional powder processing, including a console 1, a top plate 2, a cylinder 3, a load plate 4, a packaging container 5, a silo 6, a retaining ring 7, a cylinder 2 8, a connecting block 9 and an adjustment plate 10. It is characterized in that: the console 1 is set on the bracket 11, and the console 1 is provided with a guide rail 12 and a vertical plate 13, the top plate 2 is set on the vertical plate 13, and the cylinder one 3 is arranged on the vertical plate 13, and a power cord 14 and a piston rod 15 are arranged on the cylinder one 3, and a connecting plate 16, a bearing block 17 and a slider 18 are arranged on the bearing plate 4, and the slider 18 is set on the guide rail 12, the packaging container 5 is movably set on the bearing block 17, the silo 6 is set on the top plate 1, and a discharge pipe 19 is arranged on the silo 6, the baffle The ring 7 is arranged in the discharge pipe 19, and the brus...

Embodiment 2

[0026] as attached Figure 4 As shown, a packaging equipment for nutritional powder processing, including a console 1, a top plate 2, a cylinder 3, a load plate 4, a packaging container 5, a silo 6, a retaining ring 7, a cylinder 2 8, a connecting block 9 and an adjustment plate 10. It is characterized in that: the console 1 is set on the bracket 11, and the console 1 is provided with a guide rail 12 and a vertical plate 13, the top plate 2 is set on the vertical plate 13, and the cylinder one 3 is arranged on the vertical plate 13, and a power cord 14 and a piston rod 15 are arranged on the cylinder one 3, and a connecting plate 16, a bearing block 17 and a slider 18 are arranged on the bearing plate 4, and the slider 18 is set on the guide rail 12, the packaging container 5 is movably set on the bearing block 17, the silo 6 is set on the top plate 1, and a discharge pipe 19 is arranged on the silo 6, the baffle The ring 7 is arranged in the discharge pipe 19, and the brush ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap