A reliable juice extractor

A juicer, a reliable technology, applied in the field of juicer, can solve the problems that the screw and the juicer cannot be separated normally, the juicer can no longer work normally, affect the crushing efficiency and juice yield, etc., so as to ensure the crushing efficiency and The effect of juice yield, reliable position and stable position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

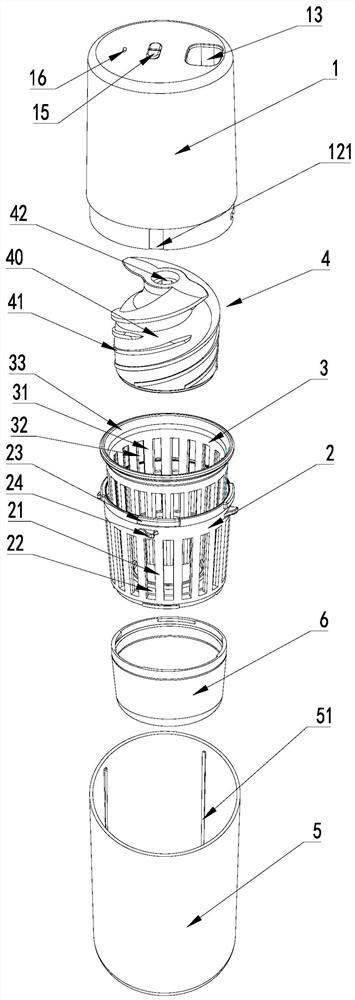

[0054] As a first embodiment of the use of a reliable juicer according to the present invention, Figure 1-3 As shown, the juicer includes a host 1, an extrusion assembly, and a juice cup 5, the extrusion assembly comprising a cross juice and screw 4 including an outer cylinder 2 and an inner cylinder of each other. 3.

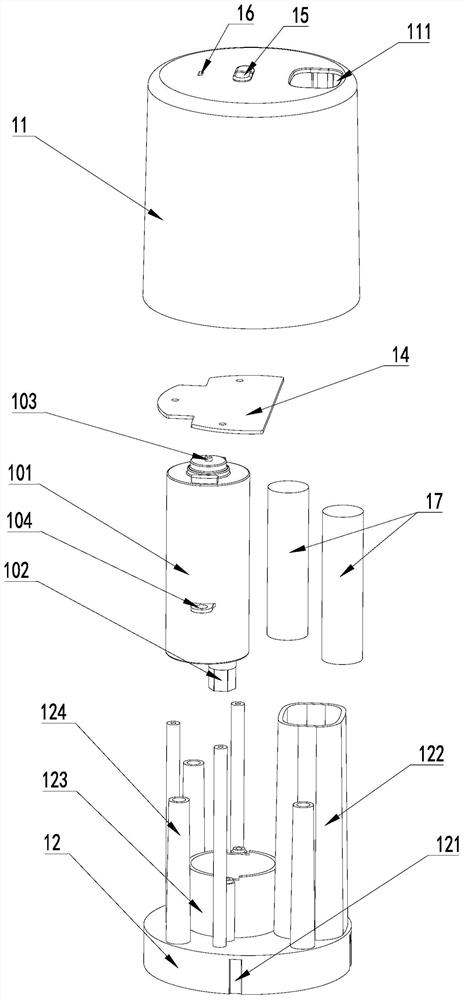

[0055] The host 1 includes a host housing 11 and a main base 12, the main chassis 12 bottom opening, which is disposed at the bottom opening of the main housing 12. An electric machine 10 is provided in the main unit 1, the motor 10 including a motor body 101 and an output shaft 102 that drive the output shaft 102 by the motor shaft 103, and the motor body 101 and the output shaft 102 have deceleration structure. The motor mount 123 is provided on the upper surface of the main base 12, and the outer surface of the motor body 101 is provided with a motor positioning seat 104, and the motor 10 is mounted at the motor mounting seat 123 and secured to the main base 12 ...

Embodiment 2

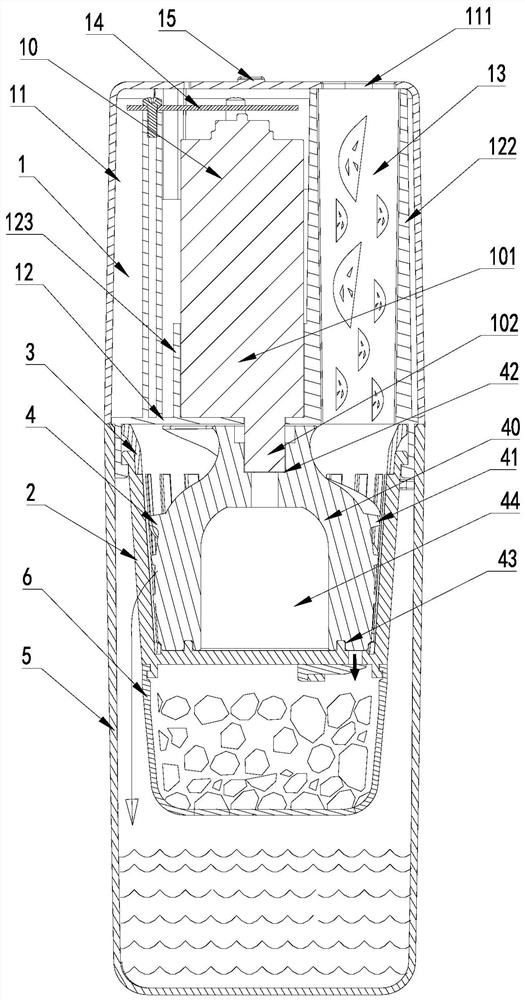

[0065] As a second embodiment of the use of a reliable juicer according to the present invention, for example, Figure 4-9 As shown, the main difference from the first embodiment is that the positioning projection further sets the positioning gap.

[0066] Such as Figure 4-9 As shown, the lower end of the main unit 1 is provided with a mounting ring 120, and an inner rotor buck 1201 is provided inside, and the inner spinbel 1201 is further provided with a limiting rib 1202, and the outer upper end of the outer tube 2 is provided. The outer rotor buckle 23, the outer spin pad 23 is rotatably blended with each other, and the limit rib 1202 prevents excessive rotation of the outer rotary buckle 23 to limit the outer cylinder 2 normally installed. The positioning projection 24 is provided with a positioning notch 240, and when the outer cylinder 2 is installed in place, the positioning notch 240 is opposite the positioning groove 121, at which time the juice cup 5 is mounted, the posit...

Embodiment 3

[0079] As a third embodiment of the use of a reliable juicer according to the present invention, for example, Figure 11 , 12 As shown, the main difference from the first example is that the positioning structure further includes a positioning rod 281 disposed at the cross.

[0080] Such as Figure 11 , 12 As shown, the outer cylinder 2 and the host 1 are provided with an outer rotor buckle 23 and the inner rotor buckle 1201, and the lower end of the host 1 is also provided with a positioning groove 121.

[0081] The outer tube 2 is provided with a positioning lever mounting table 28 having a positioning lever mounting hole 280, and the positioning rod 281 is axially active at a positioning lever mounting hole 280. The positioning lever mounting table 28 is also provided with a first elastic member 282 that pushes the positioning rod 281, and the first elastic member pushes the positioning rod to disengage from the positioning slot 121.

[0082] The inner side of the jutring cup 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com