Split type self-protection sealing surface structure of regulating valve

A split-type, self-protecting technology, applied in the valve's device for absorbing fluid energy, sliding valve, valve details, etc., can solve the problem of scouring at the bottom of the valve core, and achieve the effect of convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

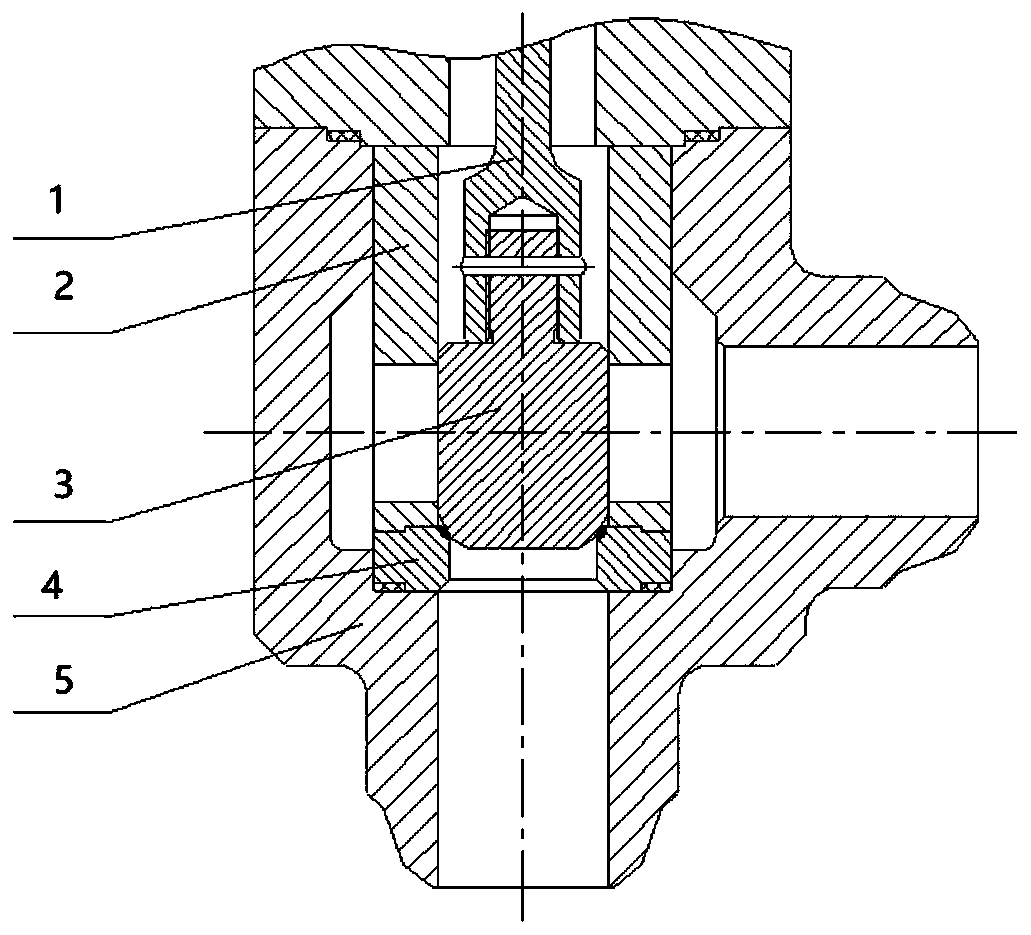

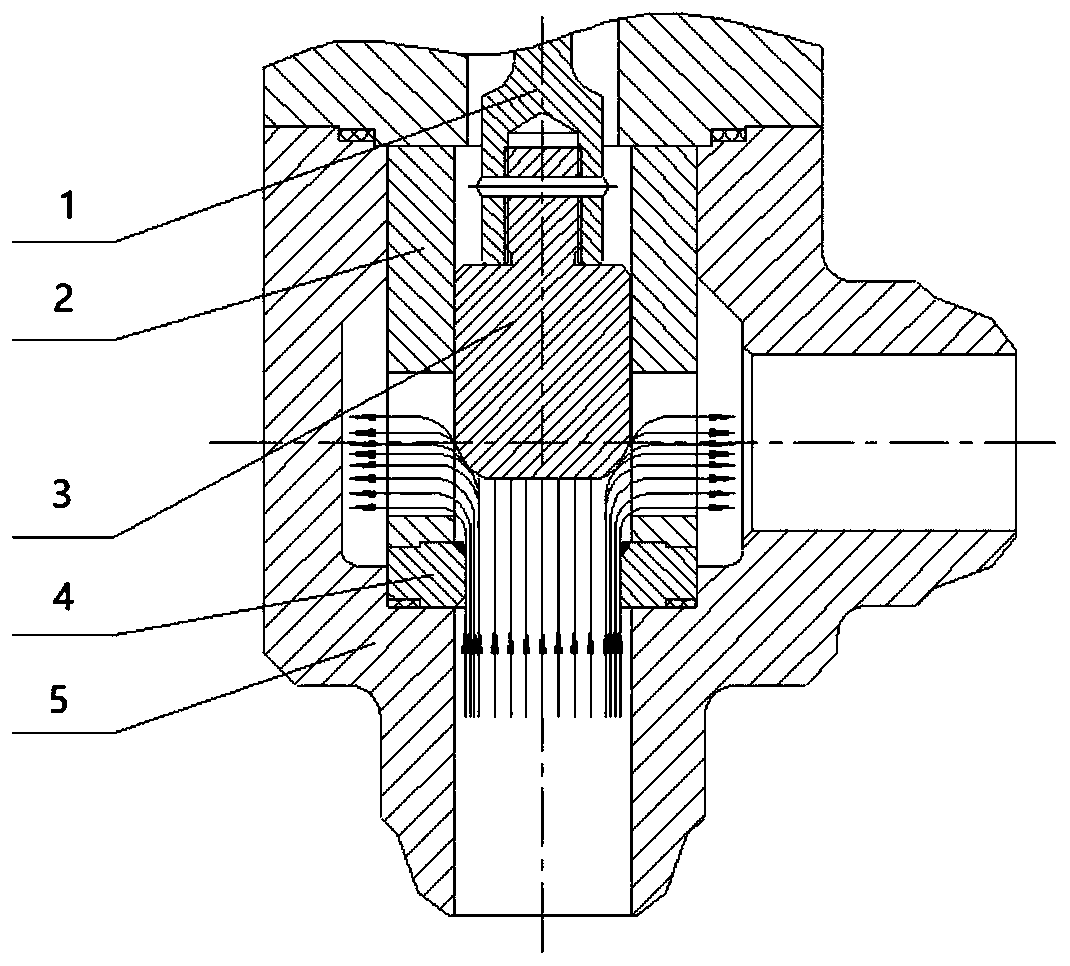

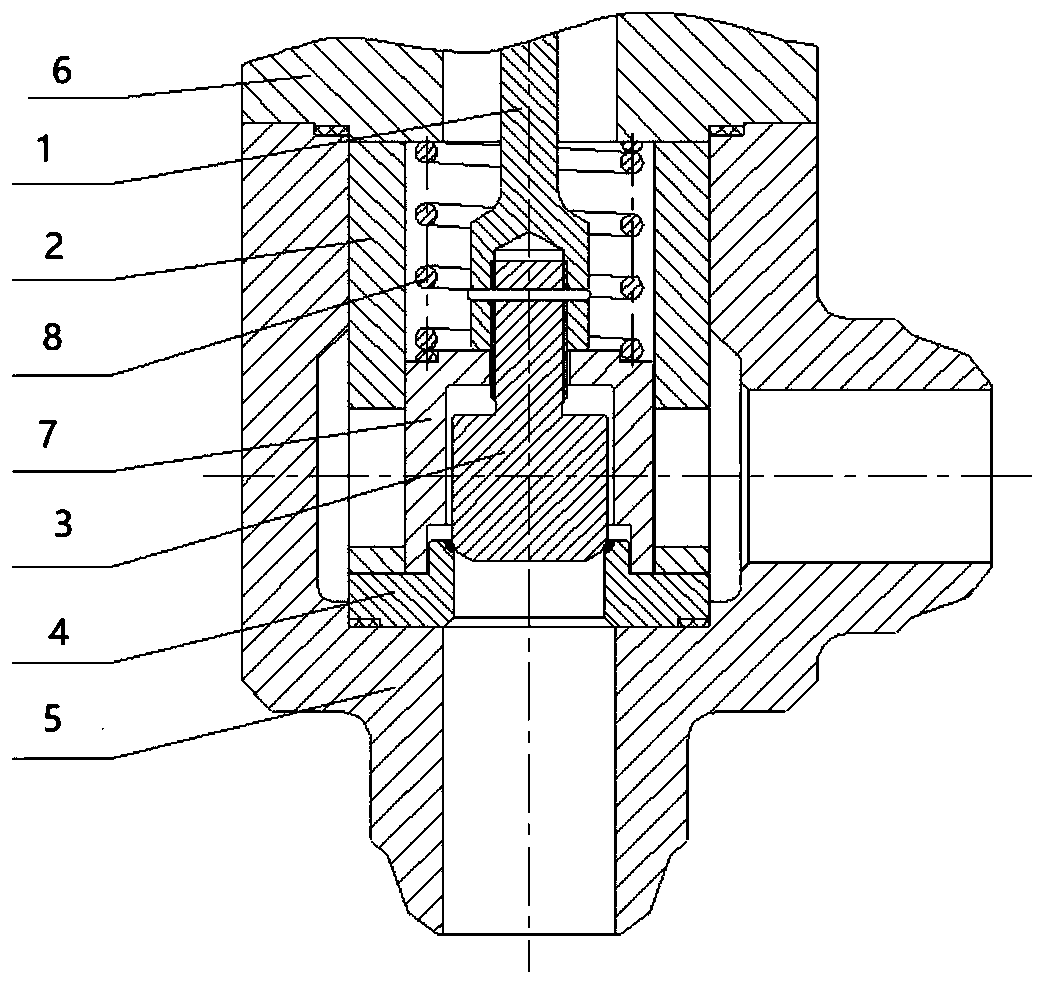

[0017] Such as image 3 As shown, a control valve split self-protection sealing surface structure of the present invention includes a valve stem 1, a sleeve 2, a valve core 3, a valve seat 4, a valve cover 6 and a valve body 5, and the innermost end of the valve body 5 is a valve Seat 4, valve core 3 is located in the valve body 5, the upper part of the valve seat 4, the lower end of the valve stem 1 extends through the valve cover 6 into the valve body 5 and connects with the valve core 3, and the valve core 3 is provided with valve core protection Device 7, a sleeve 2 is provided on the outside of the spool protection device 7, and the key to improving its structural design is that a spool protection device 7 is arranged on the periphery of the spool 3, and the height of the internal space of the spool protection device 7 is greater than the height of the spool 3, The spool 3 is allowed to move up and down in the spool protection device 7, the spool protection device 7 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com