Multi-joint robot destacking and baling production line

A multi-joint robot and production line technology, applied in packaging, conveyors, object stacking, etc., can solve problems such as low production efficiency, poor flexibility, and easy adhesion of bricks and bricks, so as to improve production efficiency and improve packaging Efficiency, the effect of brick clamping and transportation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

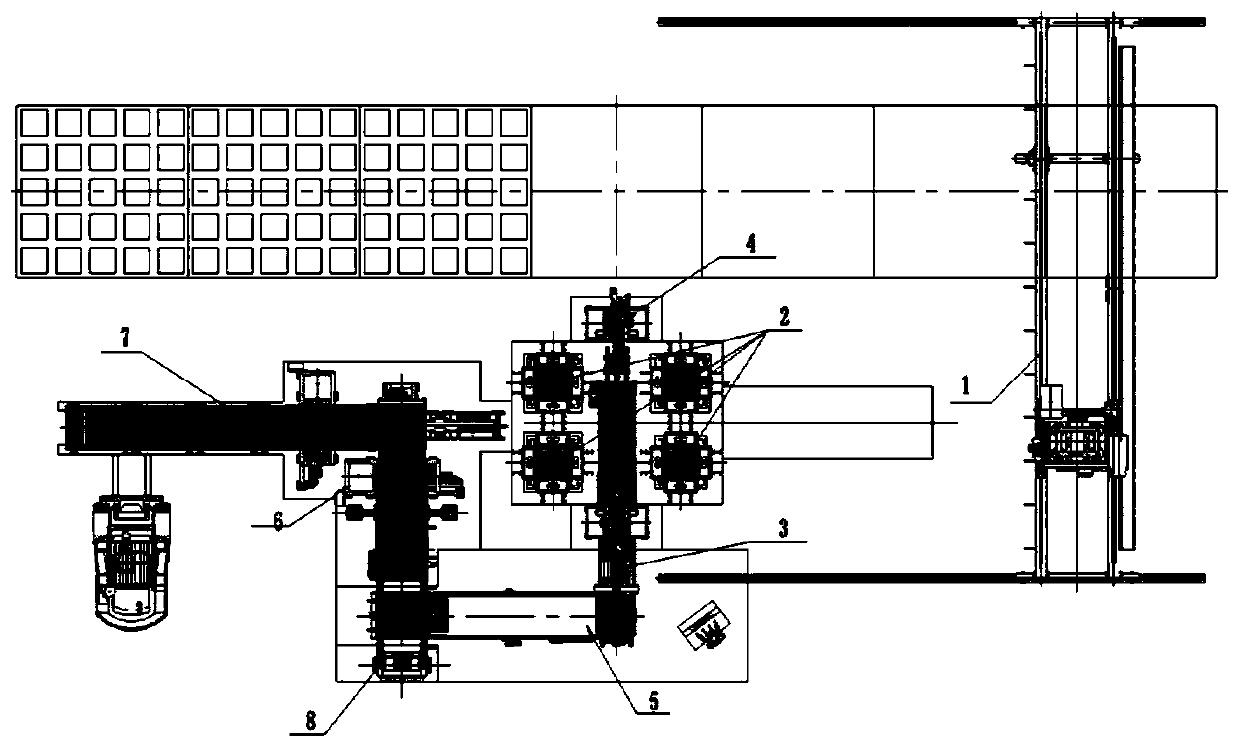

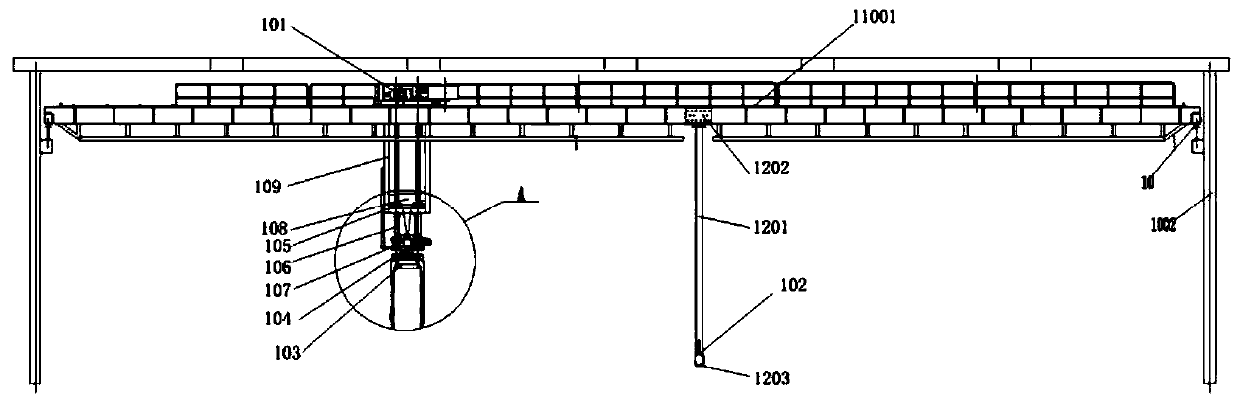

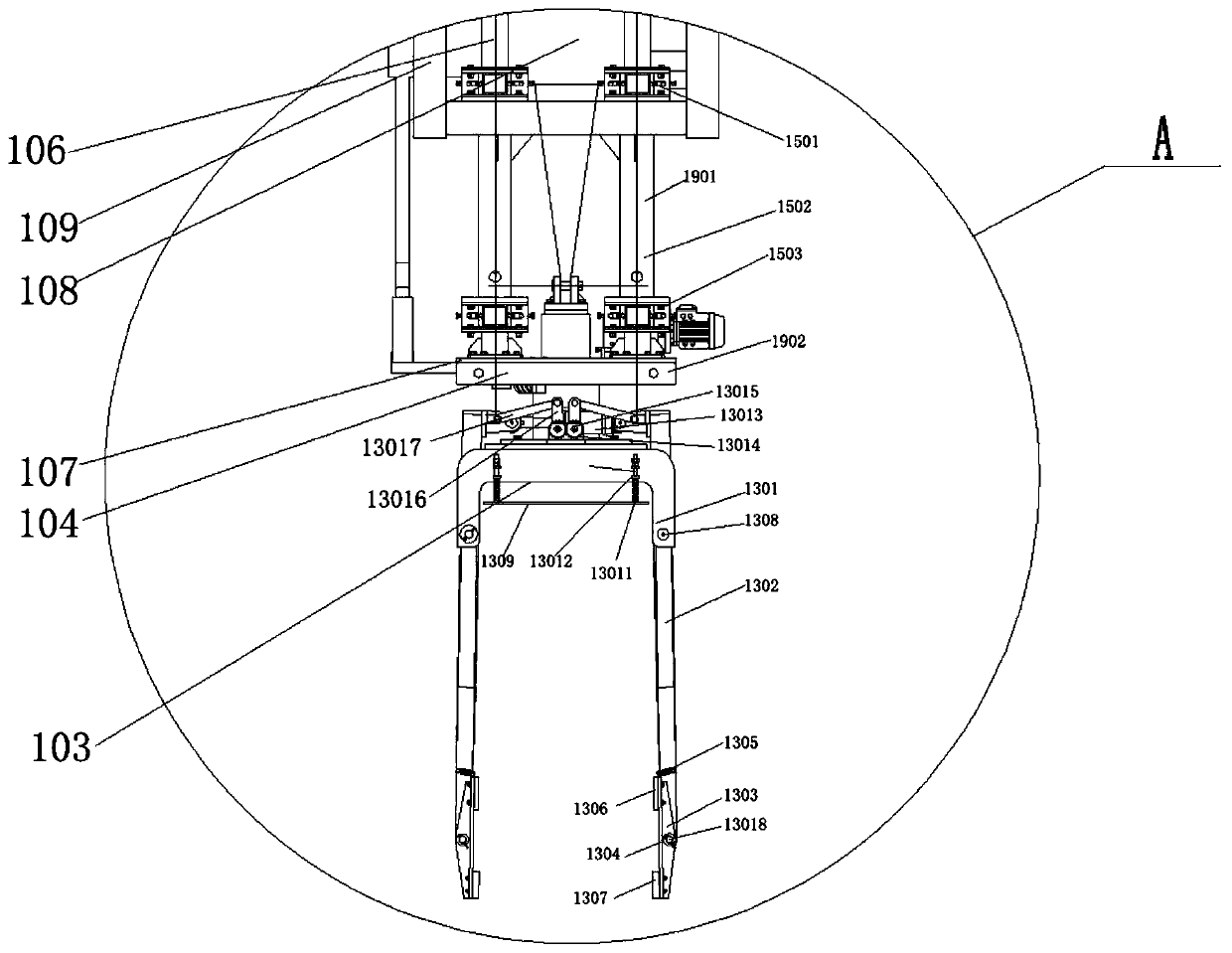

[0031] Such as Figure 1 to Figure 10 As shown, a multi-joint robot depalletizing and packaging production line includes a large-span truss brick unloading and loading equipment 1 for unloading brick stacks from the kiln car and transporting them to the stacker 2, and a brick stacker for stacking 2 The arranged brick layers are sequentially transported to the robot depalletizer 4 on the first transfer conveyor 3, the grouping machine 5 for grouping the brick layers transported by the transfer conveyor 3, and the grouping machine for grouping the grouped brick layers A stacker 8 for brick stacking, a packer 6 for packing the good brick stacks and a second transfer conveyor 7 for transporting the packed brick stacks out.

[0032]The large-span truss brick unloading and loading equipment 101 includes a truss 1010, the truss 1010 includes a beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com