Braiding positioning and placing structure of braider

A technology of positioning structure and braiding machine, applied in the field of braiding machine, can solve problems such as inability to locate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Shown in conjunction with accompanying drawing, the technical scheme of the present invention is further described:

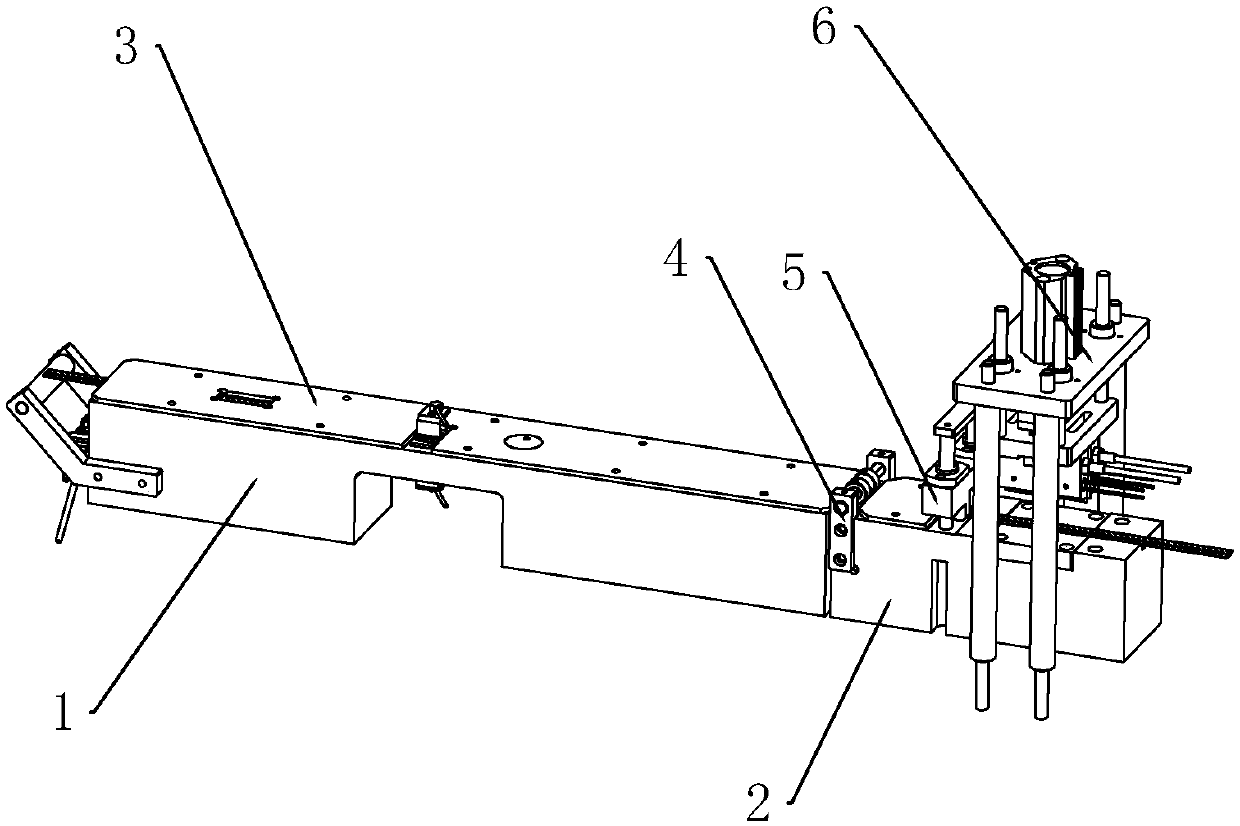

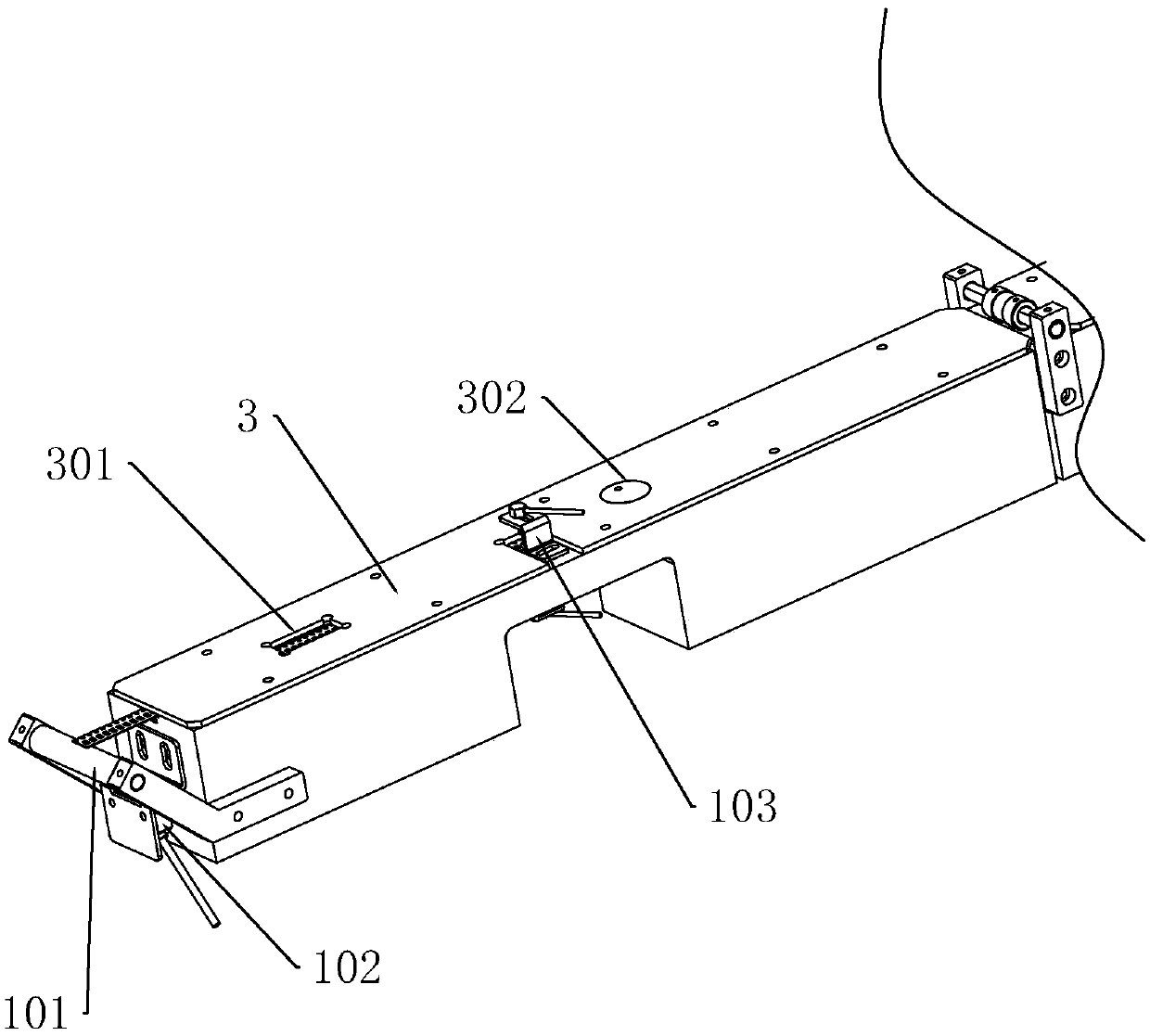

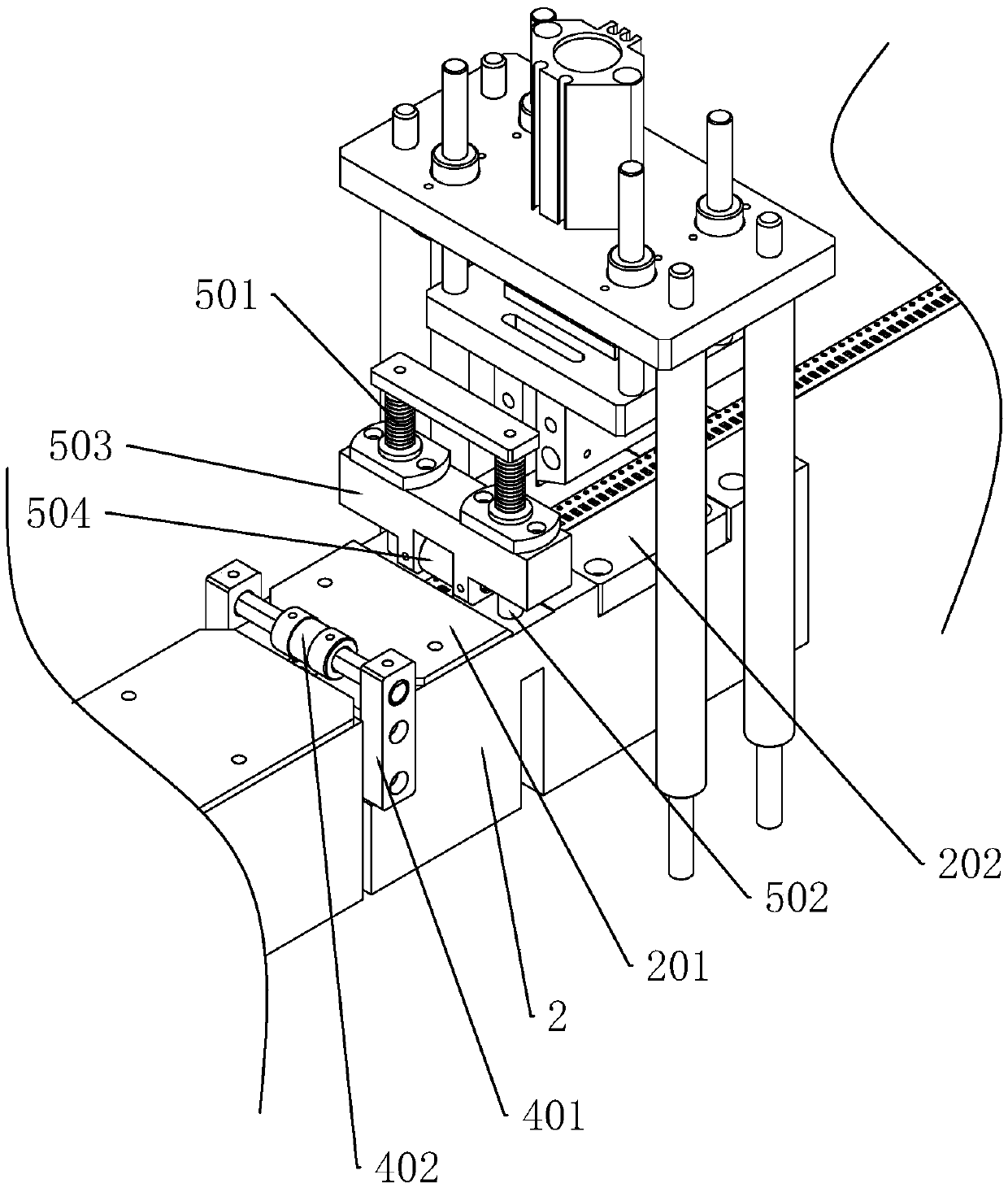

[0032] as attached Figure 1-3 Shown: a braiding positioning and placing structure of a braiding machine, including a feeding platform 1, a pressing platform 2, a first dustproof cover 3, a cover tape positioning structure 4, a bonding shock-absorbing structure 5, and a pressing structure 6. A pressing platform 2 is installed at the rear of the discharging platform 1, the first dust-proof cover 3 is attached to the upper surface of the discharging platform 1, and the pressing platform 2 is arranged in turn near the rear of the discharging platform 1 The cover belt positioning structure 4 , the front cover plate 201 for pressing, the fitting shock absorbing structure 5 , the pressure bearing block 202 , and the pressing structure 6 are arranged above the pressure bearing block 202 .

[0033] The head end of the discharge platform 1 is provided with a car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com