Nailing device used for furniture production

A furniture and No. 1 technology, applied in nailing tools, manufacturing tools, nailing tools, etc., can solve the problems of inability to adjust the fixed range of furniture fixing components, reduce the practicability of nailing devices, etc., to improve practical value, Increase the fixed range, increase the effect of spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

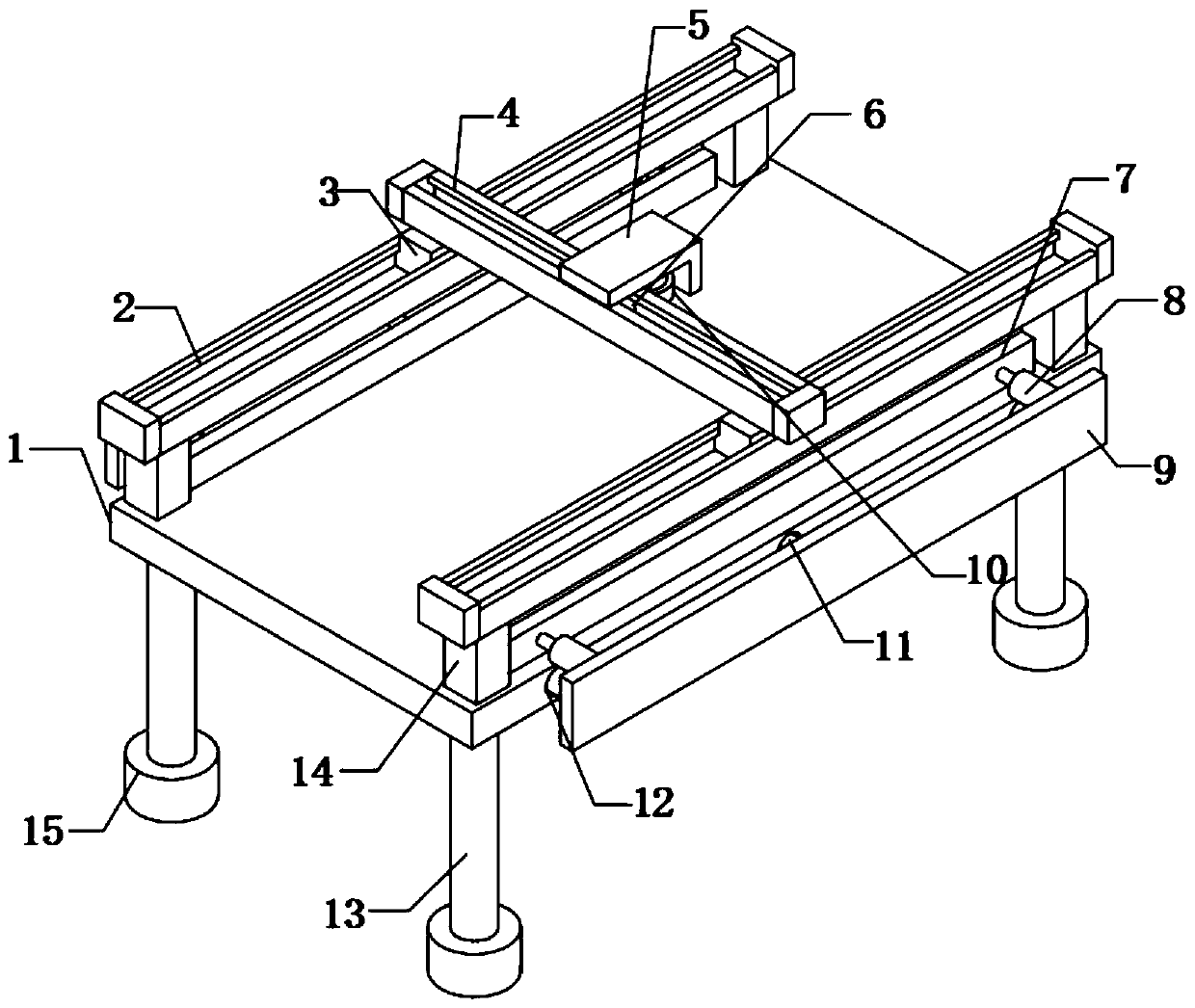

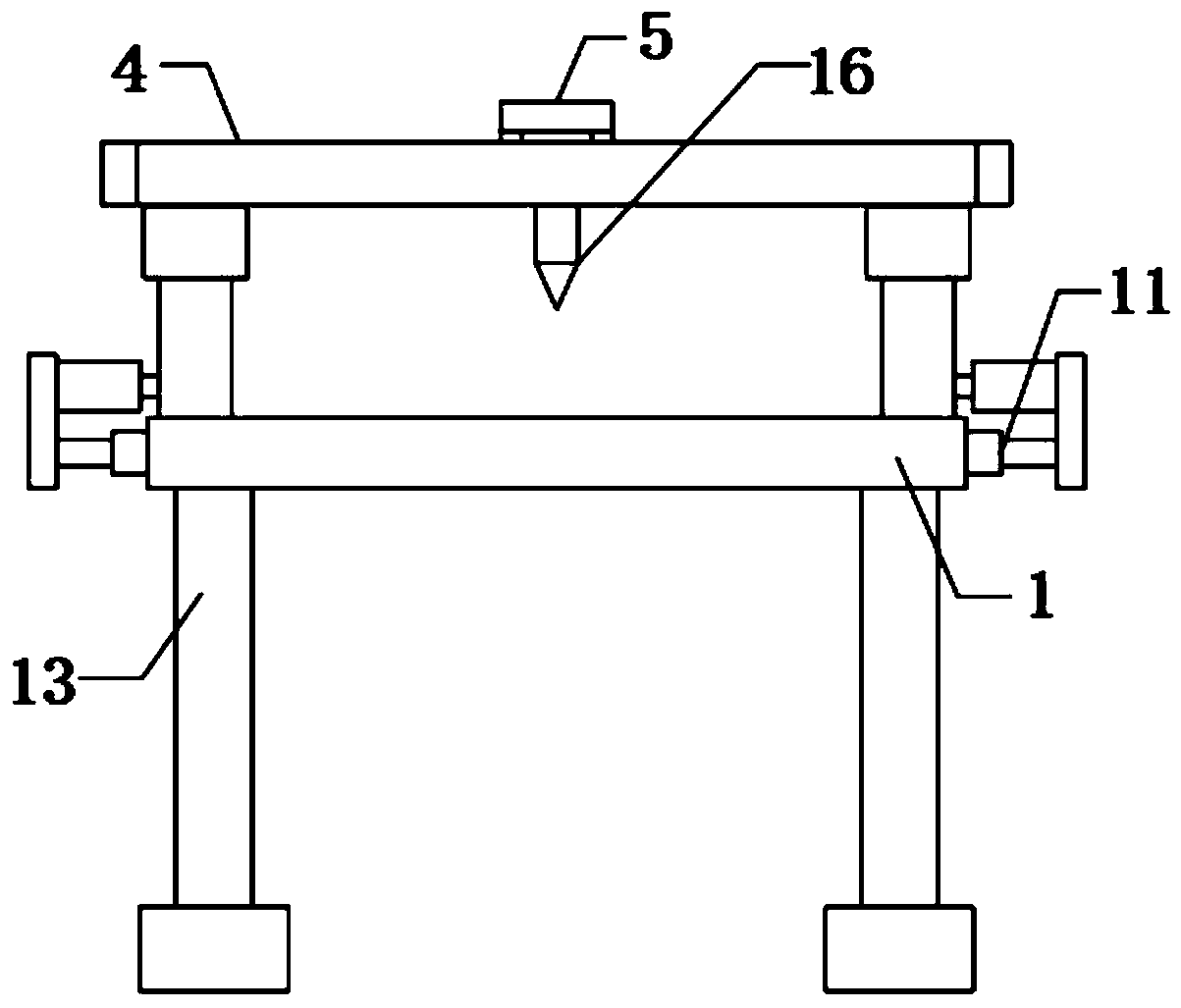

[0023] refer to Figure 1-2 , a nailing device for furniture production, including a workbench 1, grooves 12 are opened on both sides of the workbench 1 at equal distances, and the inner wall of each groove 12 is fixed with a No. 2 hydraulic rod 11 by screws. No. 2 hydraulic rods 11 are connected with a synchronous hydraulic system, and the other ends of multiple No. 2 hydraulic rods 11 on one side are fixed with the same fixed plate 9 by screws, and the outer walls of the opposite side of the two fixed plates 9 are provided with When fixing the furniture, if the size of the furniture exceeds the surface area of the workbench 1, adjust the No. 2 hydraulic rod 11 to drive the fixing plate 9 to move, thereby increasing the distance between the fixing components and increasing the fixing range of the fixing component. Improve the practical value of the device.

[0024] Wherein, the fixing assembly includes a plurality of No. 1 hydraulic rods 8, and the plurality of No. 1 hydra...

Embodiment 2

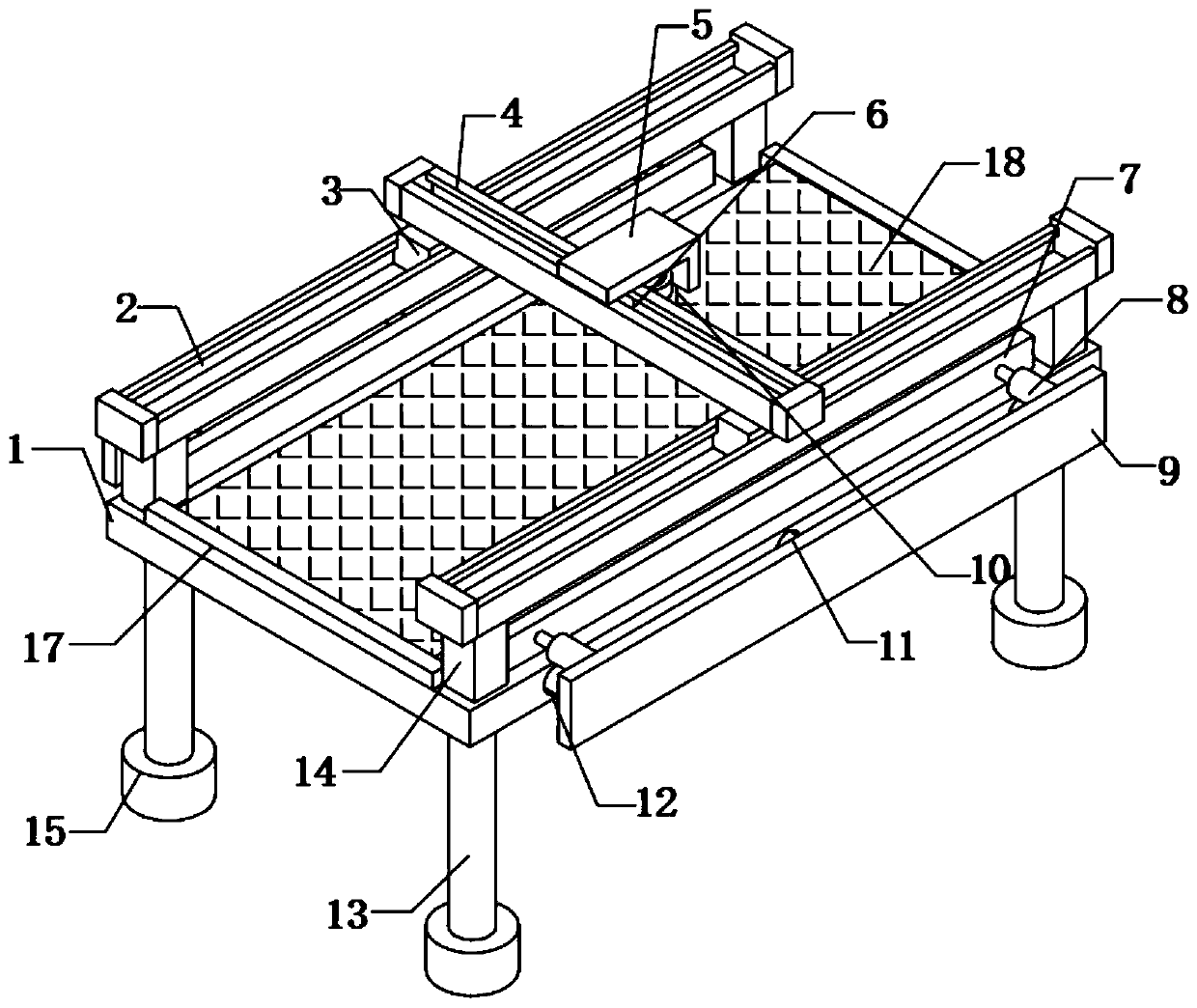

[0032] refer to image 3 , a nailing device for furniture production, including a workbench 1, grooves 12 are opened on both sides of the workbench 1 at equal distances, and the inner wall of each groove 12 is fixed with a No. 2 hydraulic rod 11 by screws. No. 2 hydraulic rods 11 are connected with a synchronous hydraulic system, and the other ends of multiple No. 2 hydraulic rods 11 on one side are fixed with the same fixed plate 9 by screws, and the outer walls of the opposite side of the two fixed plates 9 are provided with When fixing the furniture, if the size of the furniture exceeds the surface area of the workbench 1, adjust the No. 2 hydraulic rod 11 to drive the fixing plate 9 to move, thereby increasing the distance between the fixing components and increasing the fixing range of the fixing component. Improve the practical value of the device.

[0033] Wherein, the fixing assembly includes a plurality of No. 1 hydraulic rods 8, and the plurality of No. 1 hydrauli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com