Guide wheel device with three adjustable degrees of freedom

A degree of freedom and adjustable technology, applied in the field of guide wheel devices, can solve problems such as inability to control dynamically, and achieve the effects of ensuring production efficiency, improving quality and competitiveness, and high pretreatment quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

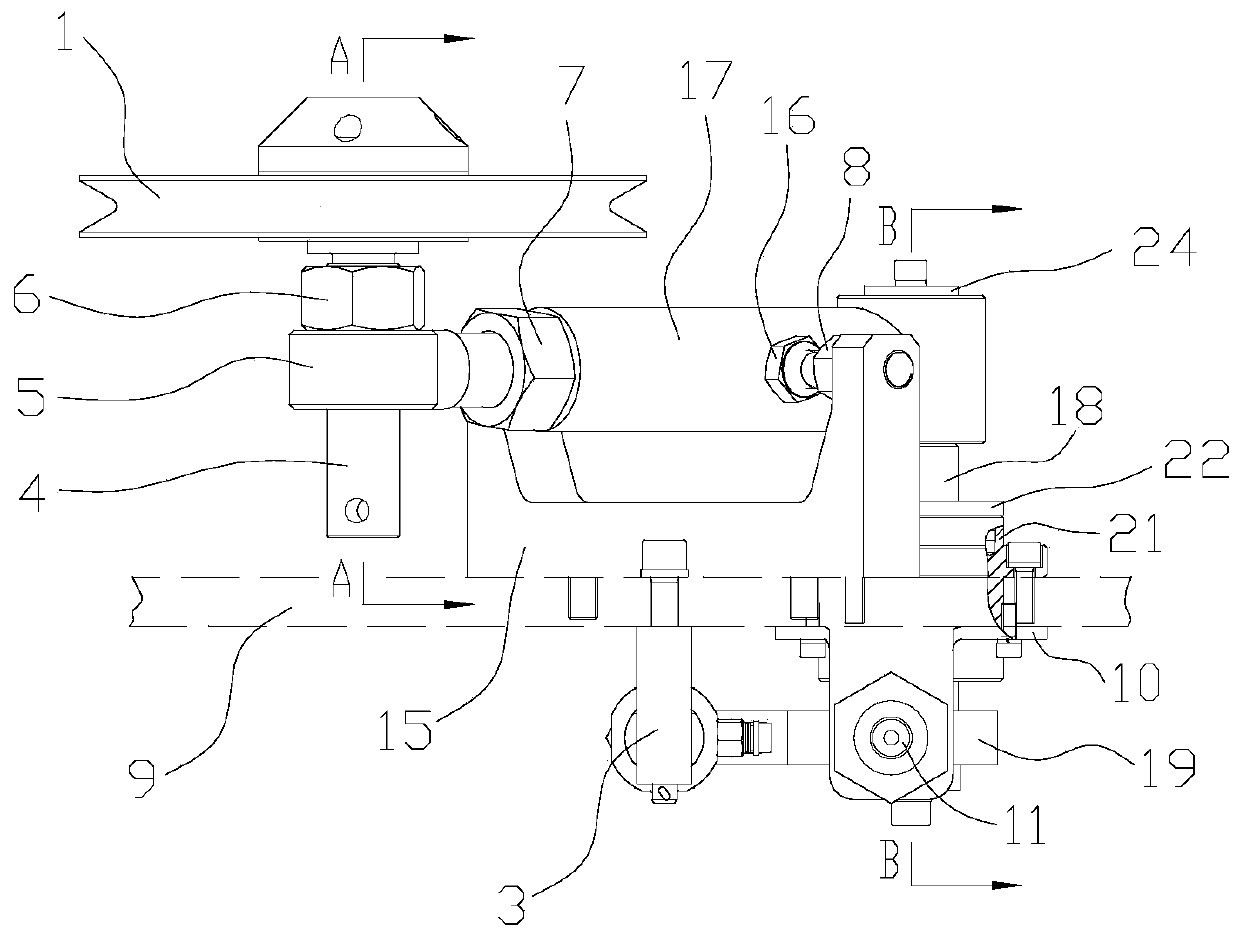

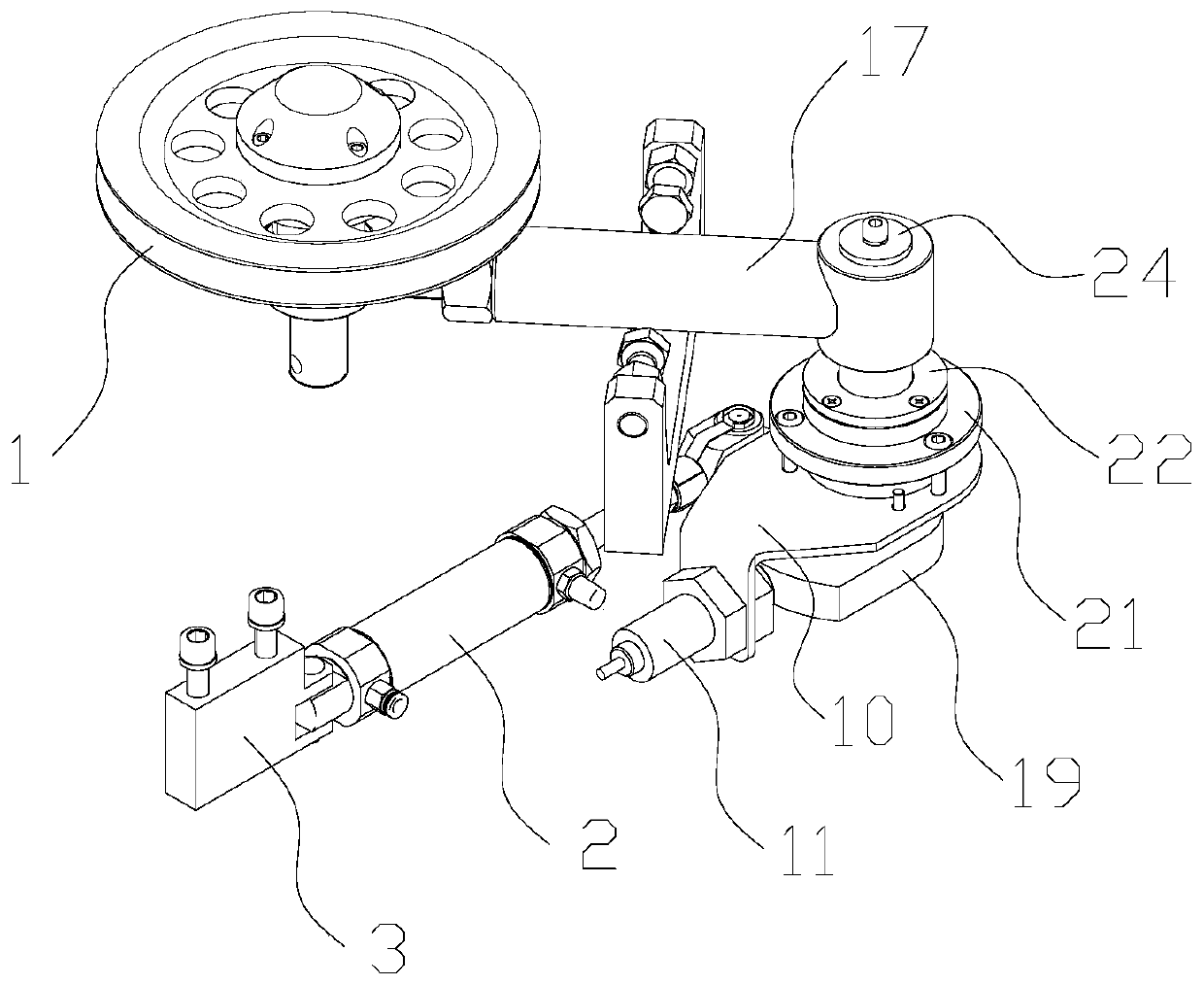

[0038] like Figure 1 to Figure 5 As shown, a guide wheel device with three adjustable degrees of freedom includes a guide wheel 1, a steering mechanism, a limit mechanism, a transmission mechanism, a monitoring mechanism, a cylinder 2 and a fixed plate 3. In this embodiment, the cylinder 2 is a single Action cylinder.

[0039] Described steering mechanism comprises mutually perpendicular vertical rotating shaft 4 and horizontal rotating shaft 5, and vertical rotating shaft 4 one end is connected with horizontal rotating shaft 5 by thread, and the other end of vertical rotating shaft is provided with guide wheel 1, and vertical rotating shaft 4 is provided with the first One adjusting nut 6, the second adjusting nut 7 is arranged on the horizontal rotating shaft 5, the vertical rotating shaft 4 realizes the position adjustment on the height direction, the horizontal rotating shaft 5 realizes the position adjustment along the axial translation of its center line, the horizontal...

Embodiment 2

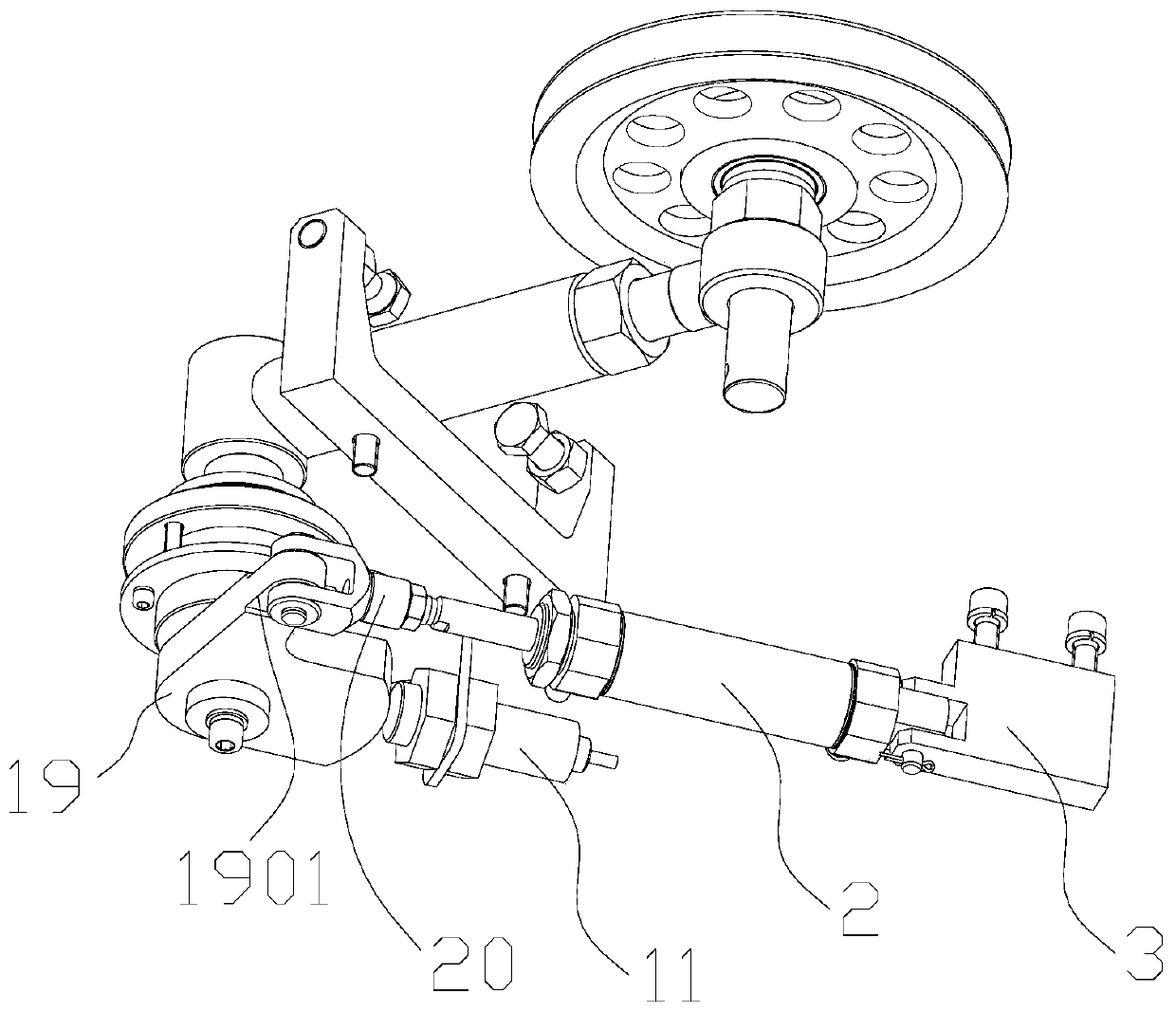

[0055] On the basis of the structure of Embodiment 1, only the structure of the monitoring board 19 is changed as follows:

[0056] like Figure 10 As shown, the monitoring surface 1902 is a radius gradient surface, the center of the monitoring surface 1902 coincides with the centerline of the axis 18, the centerline projection point of the axis 18 is collinear with the centerline of the sensor 11, and the center of the monitoring plate 19 around the axis 18 When the line rotates, the distance between the monitoring surface 1902 and the sensor 11 will change, and the sensor 11 will output a signal to control the push rod of the cylinder 2 to expand and contract through the control system, so as to realize the dynamic adjustment of the position of the guide wheel 1 during the production process and ensure that the guide wheel is always guided. Wheel 1 is within the sweet spot range.

[0057] The present invention provides a guide wheel device with three adjustable degrees of f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com