A preparation system and method of high-pressure mixed gas

A mixed gas and high-pressure mixing technology, applied in mixers, chemical instruments and methods, gas and gas/steam mixing, etc., can solve problems such as inability to obtain experimental data, small sample content, low gas density, etc., to ensure purity, The effect of preventing waste and improving the safety factor of high voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

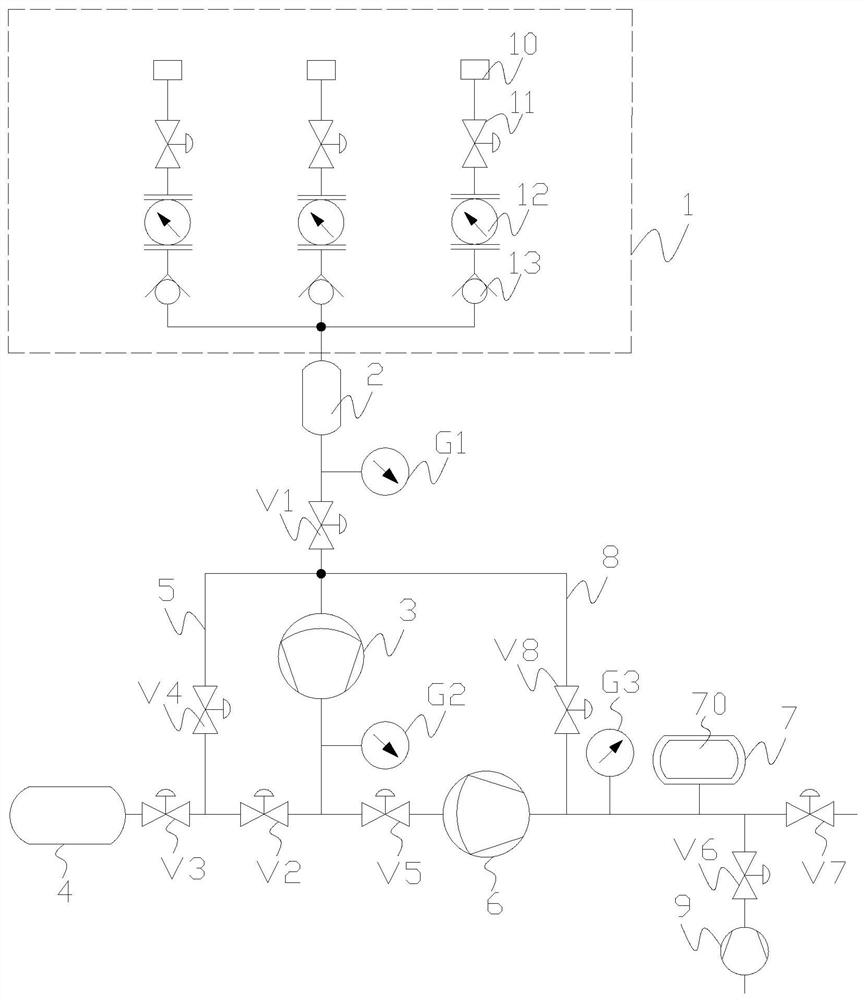

[0049] A high-pressure mixed gas preparation system, such as Figure 1a As shown, the preparation system includes a gas source control part 1, a buffer tank 2, a first supercharger 3, a mixed gas container 4, a second supercharger 6, and a sampling chamber 7. The gas source control part 1 is used to provide the preparation and mixing Various gases required for gas. The quality of the mixed gas stored in the sampling chamber 7 is less than that of the mixed gas container 4, that is, the capacity for storing the high-pressure mixed gas inside the sampling chamber 7 is smaller than the capacity for storing the high-pressure mixed gas inside the mixed gas container 4.

[0050] The air source control unit 1 includes multiple air source branches. In this embodiment, there are three types of air source branches, and each air source branch includes an air source 10, an air source valve 11, and a flow meter connected in sequence. 12. The one-way valve 13 is connected with the air inlet...

Embodiment 2

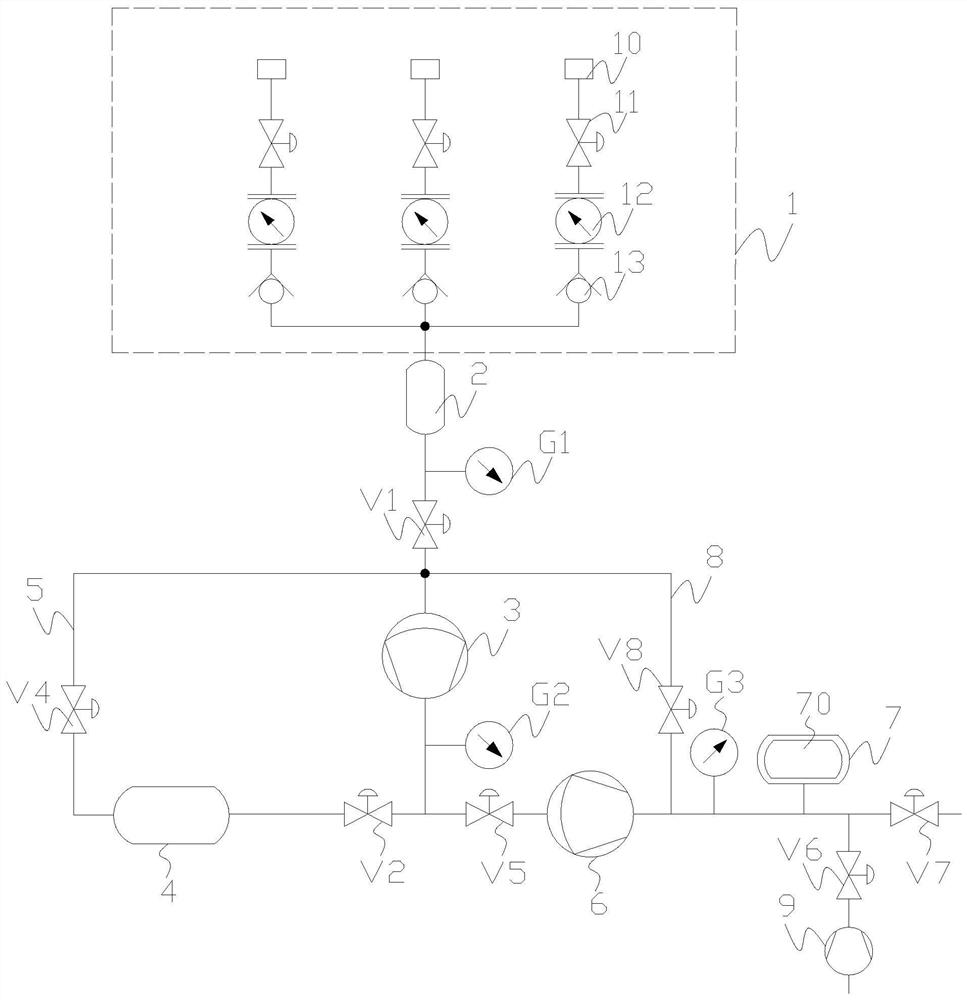

[0059] On the basis of Example 1, such as figure 2 As shown, in the present embodiment, each air source branch includes an air source 10 and an air source valve 11 connected in sequence. It communicates with the air inlet of buffer tank 2. The rest is the same as in Example 1. When preparing the mixed gas, open the gas source valve 11 of one of the gas source branches separately, and when the gas flow reaches the set value, close the gas source valve 11 of the gas source branch. Open the gas source valves 11 of other gas source branches in turn.

Embodiment 3

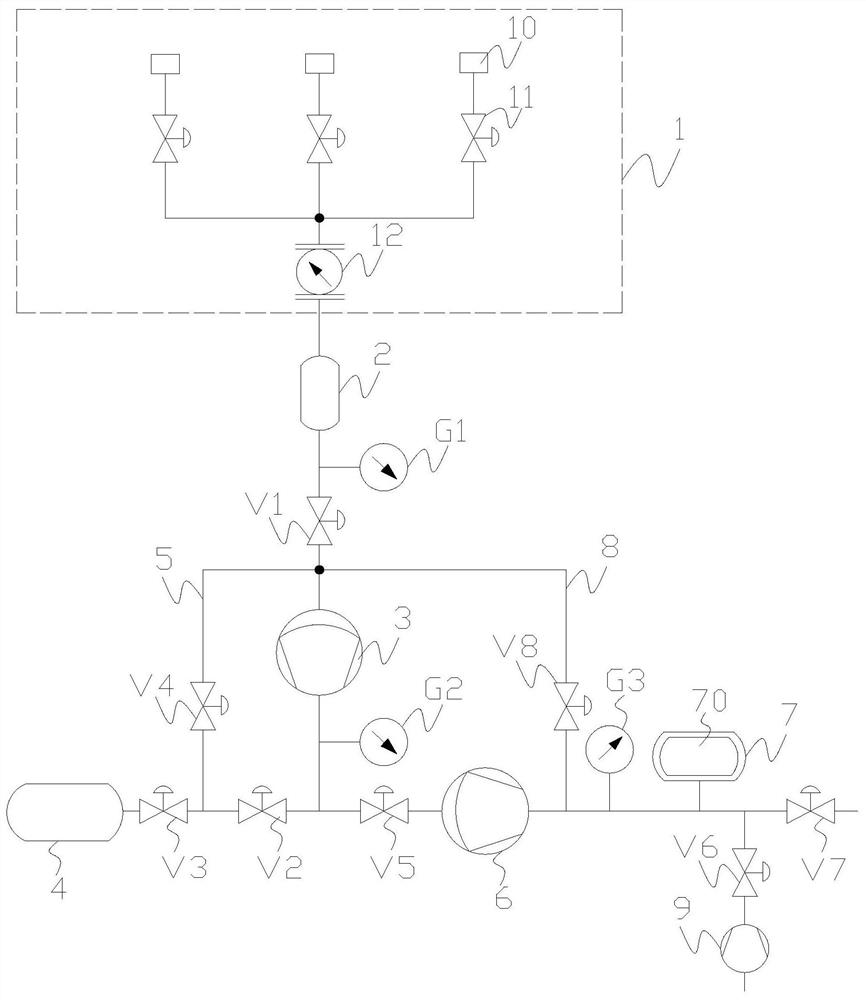

[0061] On the basis of embodiment 1, 2, as image 3 As shown, the number of mixed gas containers 4 is three groups, and the gas inlet and outlet of each mixed gas container 4 is provided with a corresponding third valve V3. When a mixed gas needs to be configured, the corresponding third valve V3 is opened. After sampling, the remaining gas is recycled to the mixed gas container 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com