Back gantry spiral limiting block hidden limiting structure

A limit structure and back door technology, applied in the direction of screws, connecting components, threaded fasteners, etc., can solve the problems of insufficient limit accuracy, poor quality of parts, looseness, etc., to ensure the convenience of installation and the quality of parts The effect of lifting and improving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

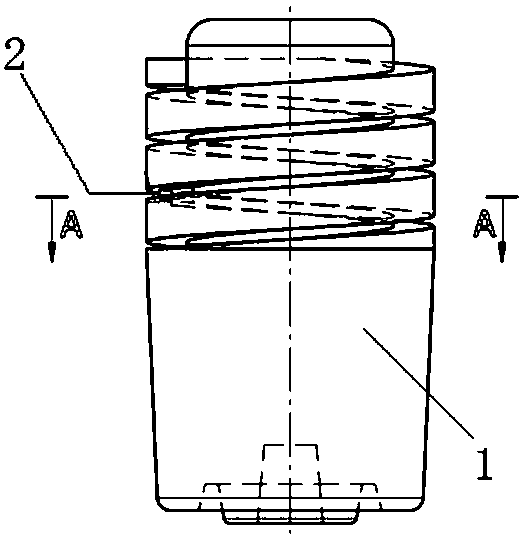

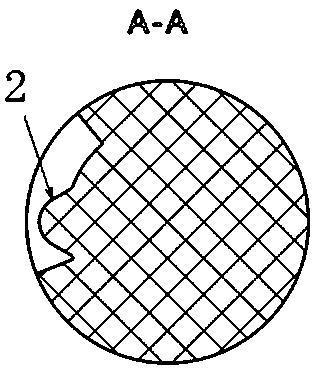

[0011] The back door screw stop block 1 made of rubber is used to connect with the threaded hole with internal threads on the inner sheet metal of the back door, and the upper part of the back door screw stop block 1 is a threaded part with external threads ,like figure 1 and figure 2 As shown, a radial protrusion along the back door screw limit block 1 is set between the tooth bottoms of two adjacent helix lines at the extreme screw-in position at the bottom of the threaded portion of the back door screw limit block 1 The hidden limit structure 2 (the limit screw-in position is determined by different back door screw limit blocks and their screw-in positions and heights, which can be grasped by those of ordinary skill in the art according to the actual situation, this embodiment In the middle, there is a hidden limit structure 2) on the part between the bottom of the second-to-last helix and the bottom of the third-to-last helix of the threaded part from top to bottom. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com