Linear vibrator

A linear vibrator and vibrating part technology, applied in the direction of electrical components, electromechanical devices, etc., can solve the problems of small adjustable space, lower process yield, and large appearance size, so as to reduce the difficulty of process assembly and improve the design of light and thin , The effect of improving the reliability strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

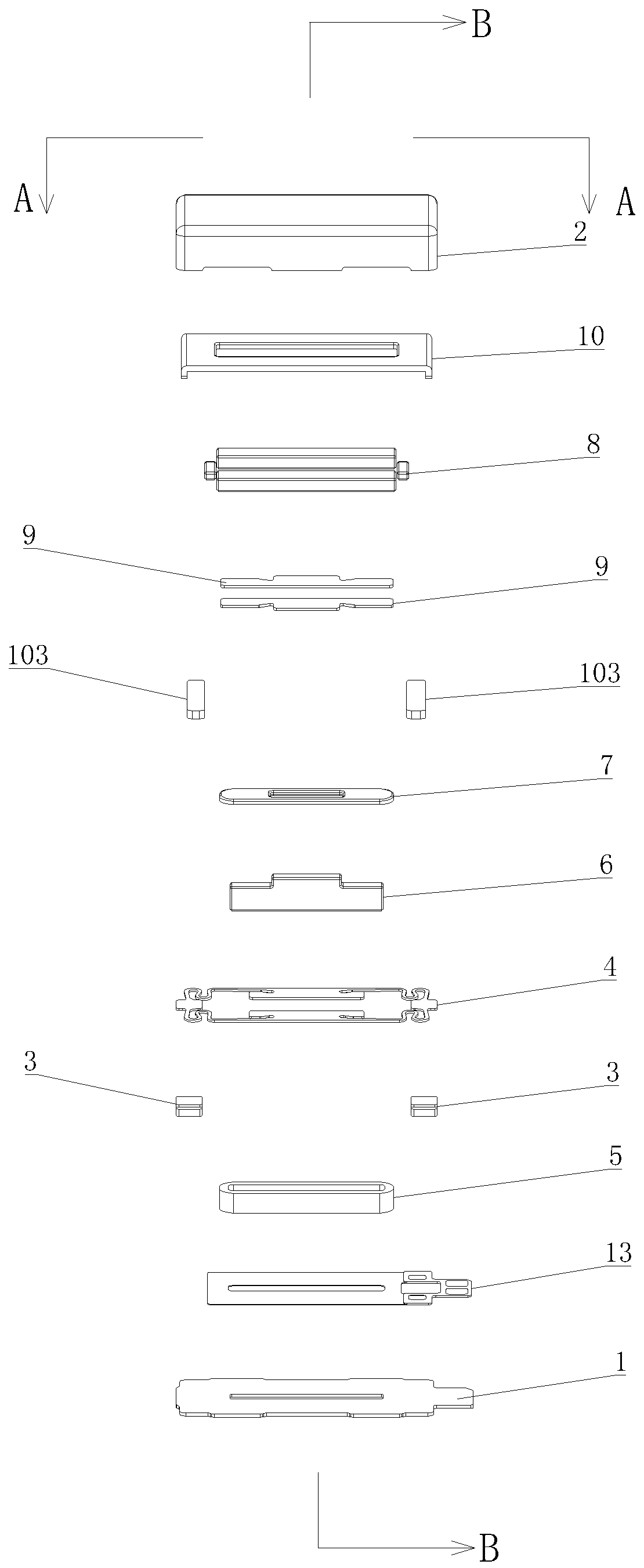

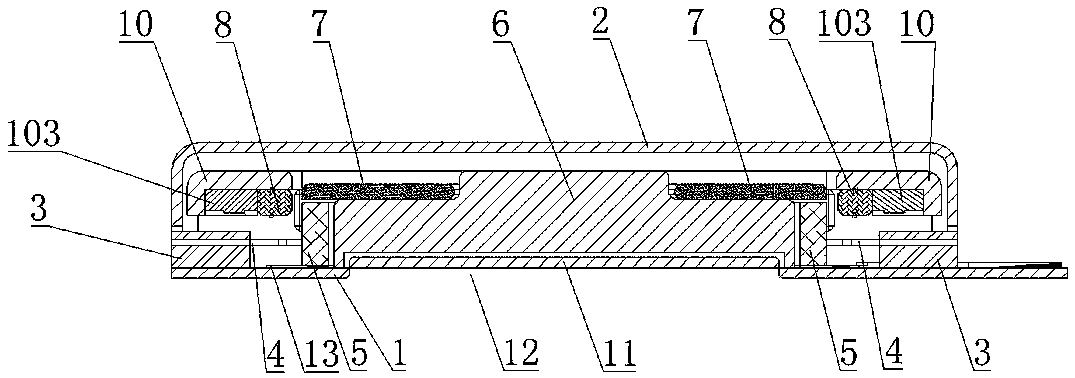

[0053] Embodiment 1: as attached Figure 1-14 As shown, a linear vibrator includes a housing, a magnet and a shrapnel 4, the housing includes an upper housing 2 and a lower housing 1, the upper housing 2 and the lower housing 1 are fixedly connected, and a cavity for accommodating other components is formed inside the housing body, the housing is fixed with two positioning parts, in this embodiment, the positioning part is a support block 3, the two support blocks 3 are respectively welded on the housing, the support block 3 is welded on the lower shell 1, and the two Elastic pieces 4 are fixedly connected between the supporting blocks 3 , and a through hole 41 for accommodating the coil 5 is provided in the middle of the elastic pieces 4 .

[0054] like Figure 1-4 As shown, the elastic sheet 4 is a flat elastic sheet, and the flat elastic sheet usually refers to a spring sheet that undergoes vertical elastic deformation in a plane, which is hollowed out on a flat elastic ma...

Embodiment 2

[0066] Embodiment 2: as attached Figure 15 And attached Figure 16 As shown, the vibrating part further includes two second vibrating parts 46 disposed opposite to each other, the second vibrating parts 46 are connected to the vibrating arm 44, and the second vibrating parts 46 are in the shape of a rectangular plate.

[0067] Other structures are the same as in Embodiment 1.

Embodiment 3

[0068] Embodiment 3: as attached Figure 17 As shown, the vibrating part further includes two second vibrating parts 46 disposed opposite to each other. The second vibrating part 46 is connected with the first vibrating part 43 to form an integrated structure. The second vibrating part 46 is in the shape of a rectangular plate.

[0069] Other structures are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com