A battery installation support for vehicle

A technology for installing brackets and batteries, which is applied to battery pack parts, circuits, electrical components, etc. It can solve the problems of inconvenient battery installation and maintenance, long positioning and adjustment time, and difficulty in moving, so that the installation and positioning process is easy and convenient. The effect of reducing physical output and simplifying the installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

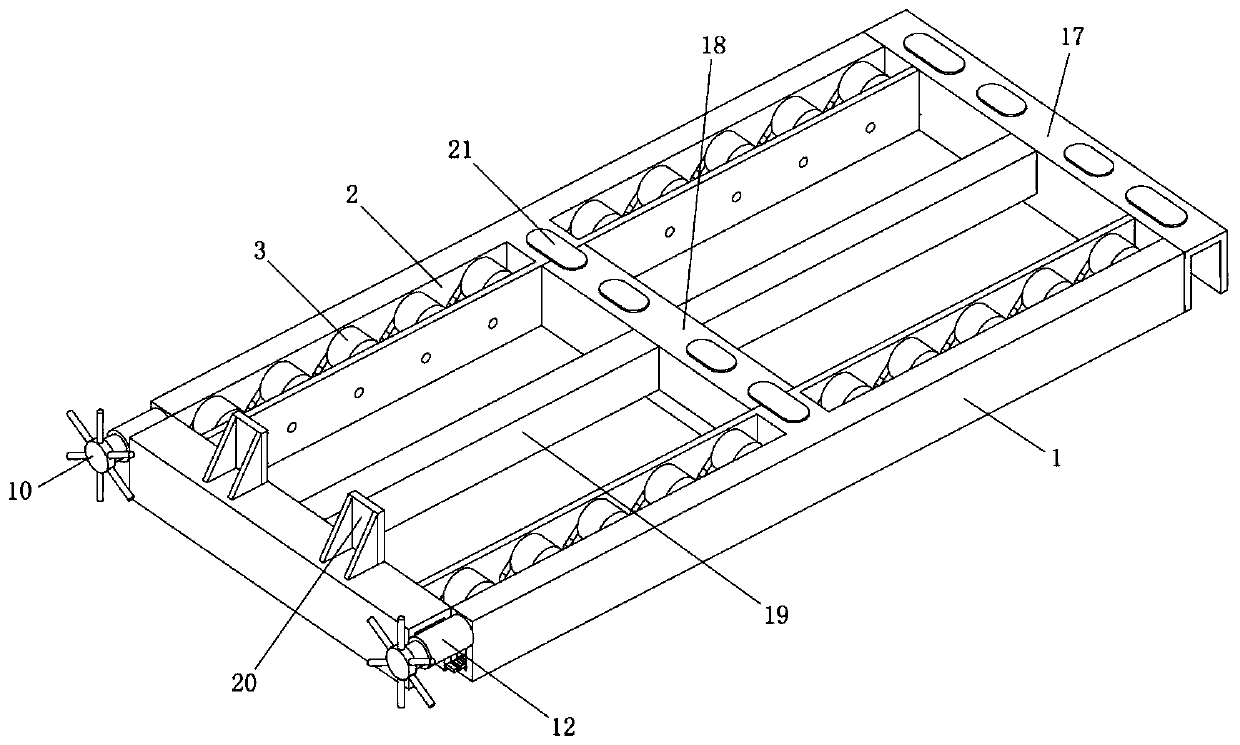

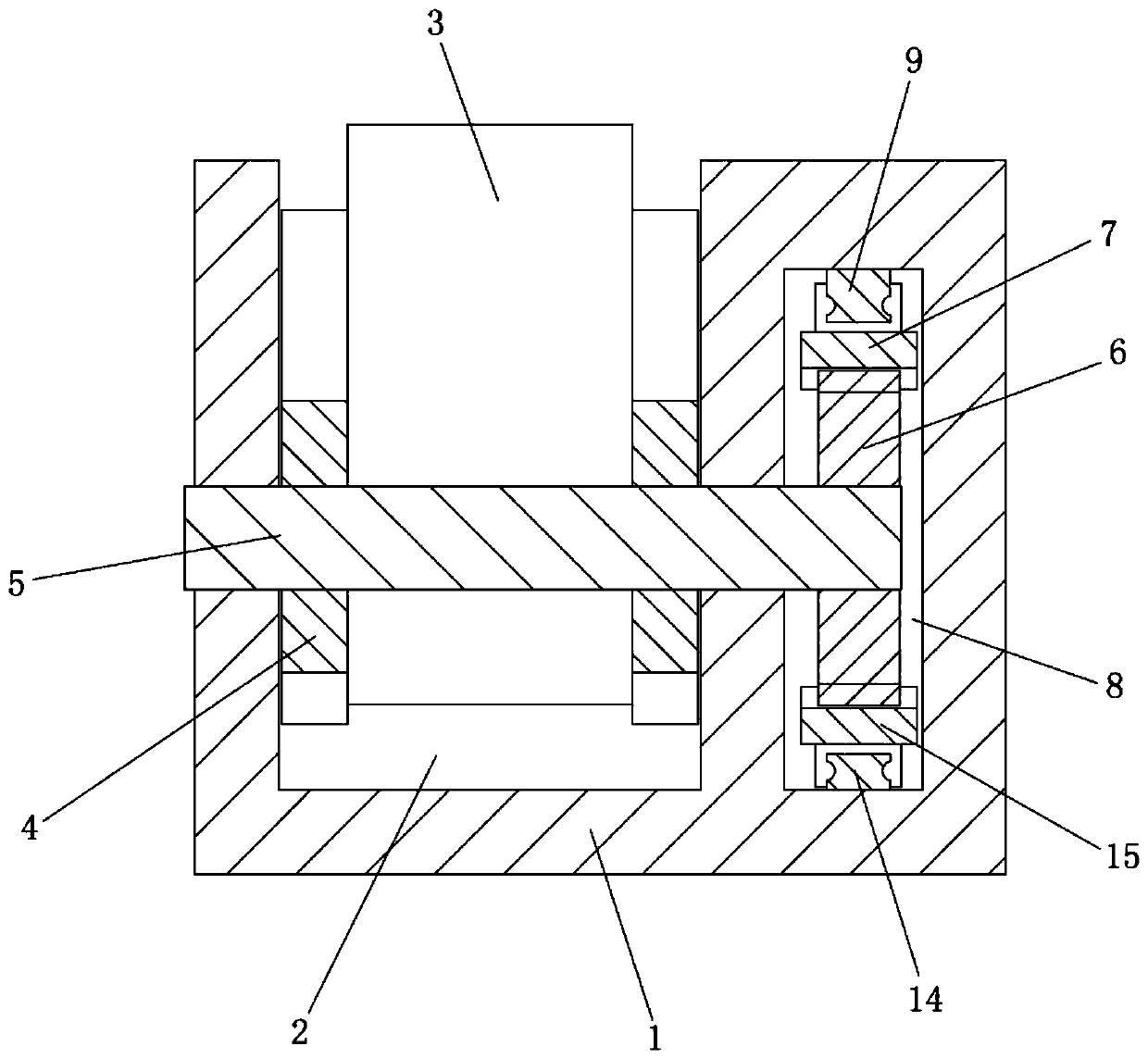

[0029] Such as Figure 1 to Figure 7 As shown, it is a battery mounting bracket for vehicles in this embodiment. The battery mounting bracket is rectangular and consists of two short beams 17 and two long mounting beams 1. The middle parts of the two mounting beams 1 are connected with Connecting beam 18, crossbeam 17 and connecting beam 18 are connected by reinforcement beam 19, and the crossbeam 17 on one side is provided with positioning block 20, and crossbeam 17, connection beam 18, reinforcement beam 19 and mounting beam 1 upper surface are flush, and crossbeam 17. Rubber pads 21 are also distributed on the upper surface of the connecting beam 18. Among them, the installation beam 1 is respectively provided with installation grooves 2 extending along the length direction, and there are multiple rollers 3 with the same rolling direction rotating in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com