Fast-installing-and-dismantling support of water drilling machine and using method of fast-installing-and-dismantling support

A water drilling rig, fast technology, applied in the direction of drilling equipment, earthwork drilling, supporting devices, etc., can solve the problems of high safety risk, non-load-bearing filling wall fixing difficulties, etc., to achieve accurate drilling positioning, convenient drilling operation, The effect of quick installation and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following description illustrates specific embodiments of the invention sufficiently to enable those skilled in the art to practice and reproduce it.

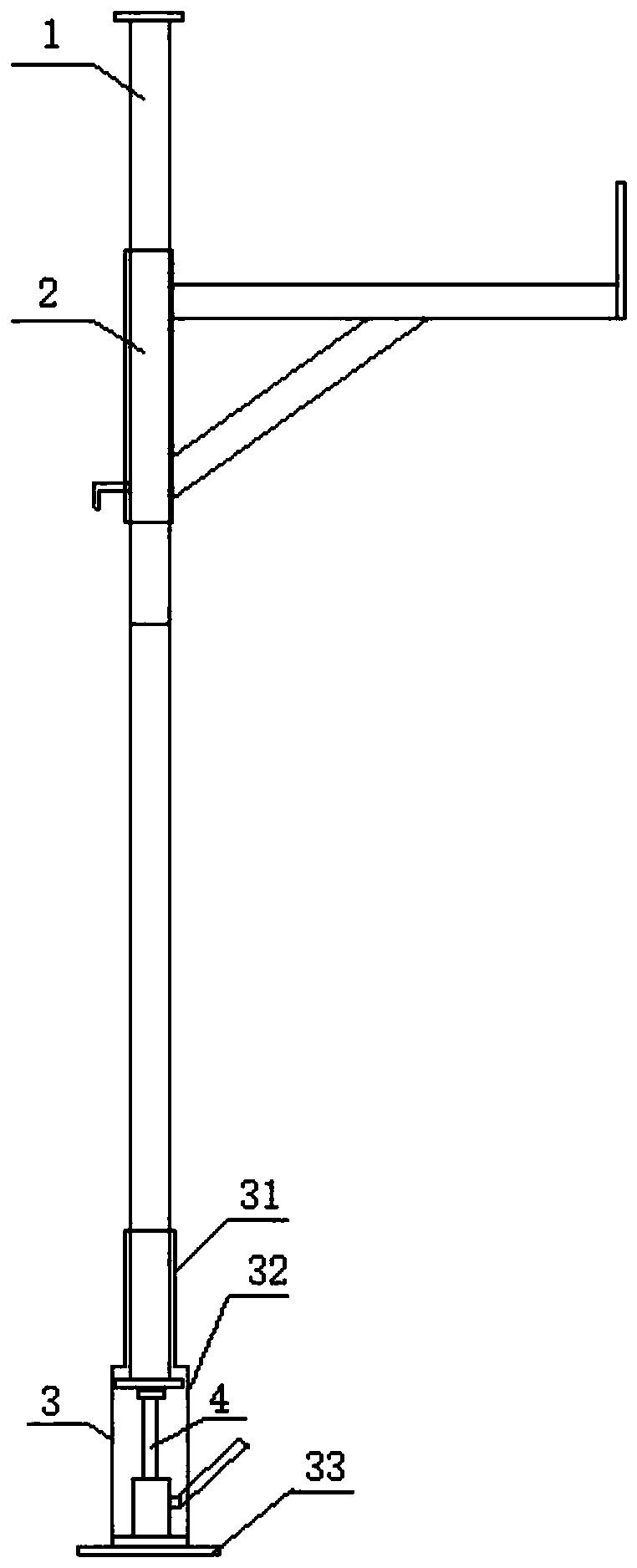

[0024] Such as figure 1 As shown, it is a structural schematic diagram of the fast installation and disassembly support of the reclaimed water drilling rig according to the present invention.

[0025] The structure of the fast installation and disassembly bracket of the water drilling rig includes: vertical pole 1, water drilling rig bracket 2, jack bracket 3, jack 4; between.

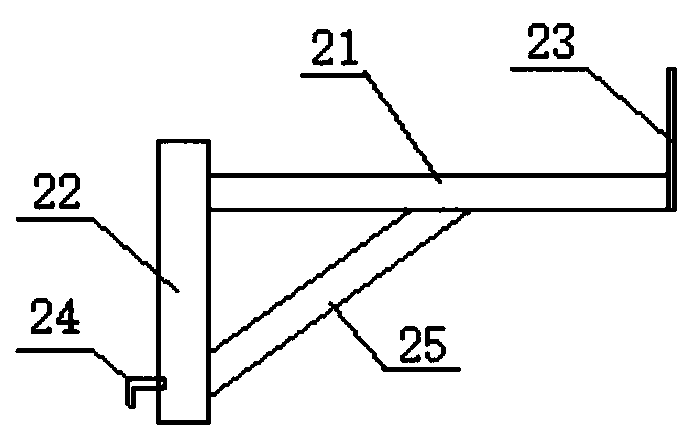

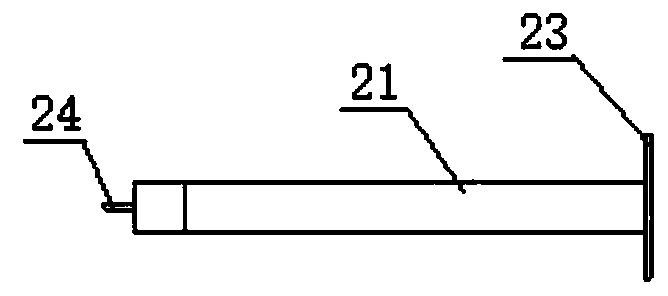

[0026] Such as figure 2 Shown, is the front view of water drilling rig bracket 2 in the present invention; As image 3 Shown, is the plan view of water drilling rig bracket 2 in the present invention; As Figure 4 Shown is the right side view of water drilling machine bracket 2 in the present invention.

[0027] The structure of water drilling rig bracket 2 comprises: cross bar 21, sliding sleeve 22, water drilling machine fixing plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com