Touch electronic knob and wiring structure thereof

A wiring structure and electronic technology, applied in circuits, electrical switches, electrical components, etc., can solve problems such as small application range, and achieve the effect of reducing resistance increase, product structure stability and life improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

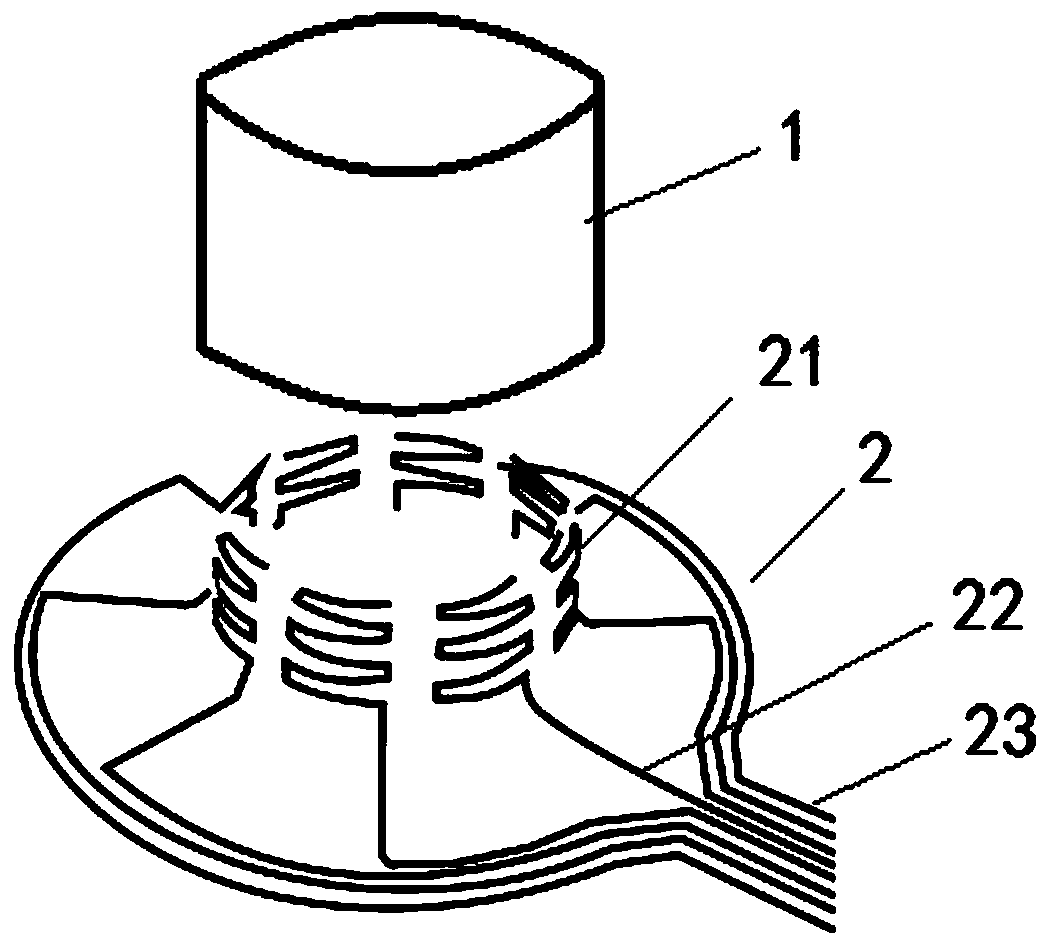

[0033] This embodiment is a wiring structure of a touch-sensitive electronic knob, refer to figure 1 As shown, the touch-sensitive electronic knob includes an operation button 1 and an induction circuit unit 2, and the induction circuit unit 2 includes a plurality of capacitive sensing lines; the operation button 1 is provided with a hollow accommodation part;

[0034] Each capacitive sensing circuit includes a rotary sensing part 21 and a signal conducting part 22 connected to each other, and the opposite end of the signal conducting part connected to one end of the rotary sensing part is the sensing output terminal 23; the signal conducting parts of a plurality of capacitive sensing lines are located in the same conducting plane , the operation button is located on one side of the conduction plane, one end of the hollow accommodation part is open and faces the conduction plane, each rotation sensing part 21 is bent toward the side where the operation button 1 is located into ...

Embodiment 2

[0047] This embodiment is a touch-sensitive electronic knob applying the wiring structure of Embodiment 1. The touch-sensitive electronic knob includes an operation button, an induction circuit unit and a functional drive circuit unit; refer to Image 6 Shown:

[0048] The sensing circuit unit includes a plurality of capacitive sensing circuits and a capacitive touch processor; the plurality of capacitive sensing circuits are wired according to the wiring structure described in the first aspect; the capacitive touch processor includes a plurality of touch signal input terminals and signal output terminals; The sensing output ends of the capacitive sensing circuit are respectively connected to a signal input end of the capacitive touch processor;

[0049] The functional driving circuit unit includes a controller, the controller includes a touch signal input end and a plurality of control signal output ends, the touch signal input end is connected to the signal output end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com