Optical imaging lens

An optical imaging lens and lens technology, applied in the field of lenses, can solve the problems of low relative illumination at the edge of the imaging surface, low pixel value, blue-violet fringing, etc., and achieve good image color reproduction, high unit pixel ratio, and uniform relative illumination. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

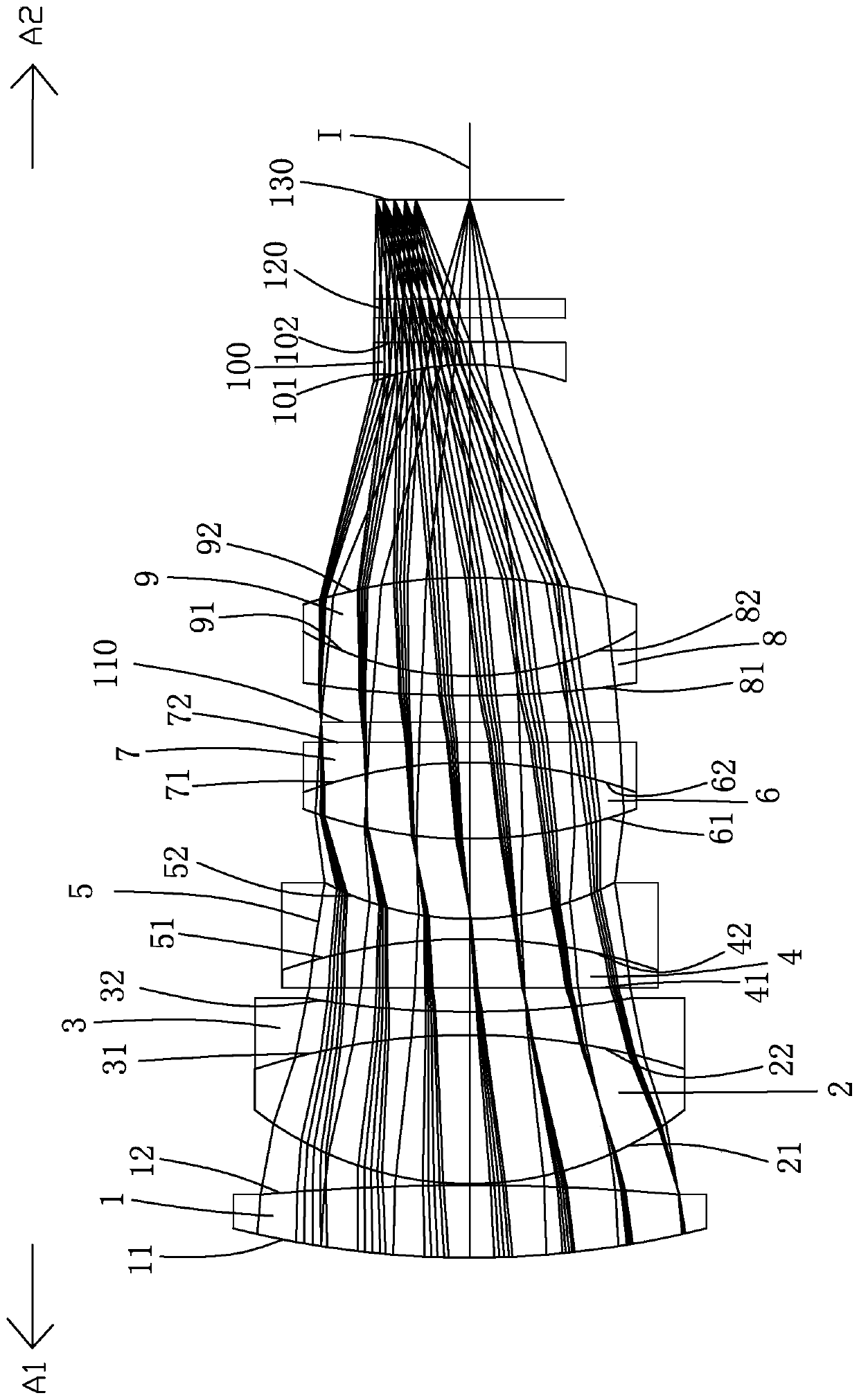

[0094] Such as Figure 7 As shown, the concave-convex surface shape and refractive power of each lens in this embodiment and the first embodiment are approximately the same, only the image side 102 of the tenth lens 100 is a convex surface, and the optical parameters such as the radius of curvature of each lens surface and lens thickness are also the same. different.

[0095] The detailed optical data of this specific embodiment are shown in Table 2-1.

[0096] Detailed optical data of Table 2-1 Example 2

[0097] surface Caliber / mm Radius of curvature / mm Thickness / mm material Refractive index Dispersion coefficient Focal length / mm - subject surface Infinity Infinity 11 first lens 44.000 84.844 6.734 H-BAK8 1.572499 57.5208 107.39 12 38.000 -220.102 0.134 21 second lens 40.000 33.236 15.010 FCD10A 1.458597 90.1949 51.19 22 40.000 -89.185 0 31 third lens 40.000 -...

Embodiment 3

[0101] Such as Figure 13 As shown, the concave-convex surface shape and refractive power of each lens in this embodiment and the first embodiment are approximately the same, only the image side 102 of the tenth lens 100 is a convex surface, and the optical parameters such as the radius of curvature of each lens surface and lens thickness are also the same. different.

[0102] The detailed optical data of this specific embodiment are shown in Table 3-1.

[0103] Detailed optical data of the third embodiment of table 3-1

[0104] surface Caliber / mm Radius of curvature / mm Thickness / mm material Refractive index Dispersion coefficient Focal length / mm - subject surface Infinity Infinity 11 first lens 44.000 84.561 6.970 H-BAK8 1.572499 57.5208 107.16 12 38.800 -220.052 0.131 21 second lens 40.000 33.270 15.063 FCD10A 1.458597 90.1949 51.18 22 40.000 -68.952 0 31 third ...

Embodiment 4

[0108] Such as Figure 19 As shown, this embodiment and the embodiment 1 have the same concave-convex surface shape and refractive index of each lens, and only the optical parameters such as the radius of curvature of each lens surface and lens thickness are also different.

[0109] The detailed optical data of this specific embodiment are shown in Table 4-1.

[0110] Table 4-1 Detailed optical data of Example 4

[0111] surface Caliber / mm Radius of curvature / mm Thickness / mm material Refractive index Dispersion coefficient Focal length / mm - subject surface Infinity Infinity 11 first lens 44.000 92.335 6.758 H-BAK8 1.572499 57.5208 106.64 12 39.000 -220.711 0.148 21 second lens 40.000 45.233 15.272 FCD10A 1.458597 90.1949 51.28 22 40.000 -81.374 0 31 third lens 40.000 -81.374 1.987 FD60-W 1.805181 25.4564 -48.50 32 28.657 77.268 2.078 41 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com