Multifunctional back door lock reinforcer, back door and automobile

A back door lock, multi-functional technology, applied in the direction of doors, building locks, vehicle locks, etc., can solve the problems of not having a back door buckle hand box installation structure, increasing the manufacturing cost of bicycles, affecting the production rhythm, etc., to improve work stability. performance, improve assembly efficiency, and enhance strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

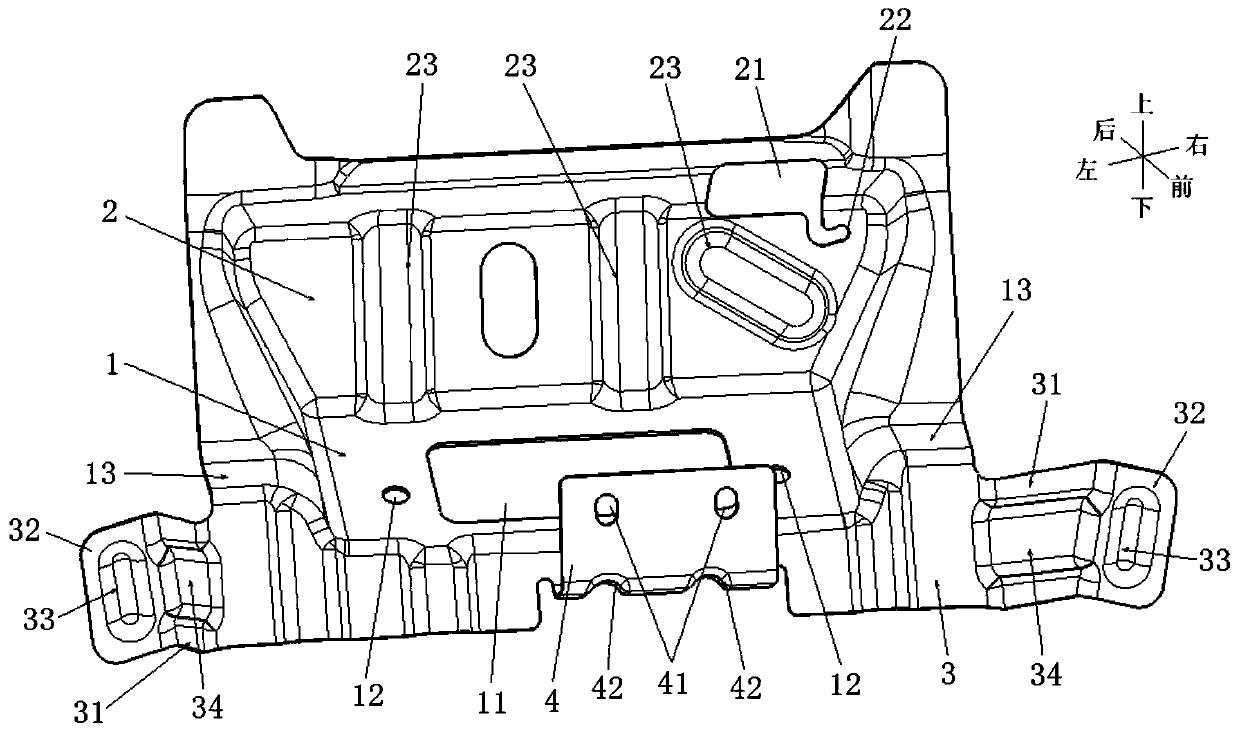

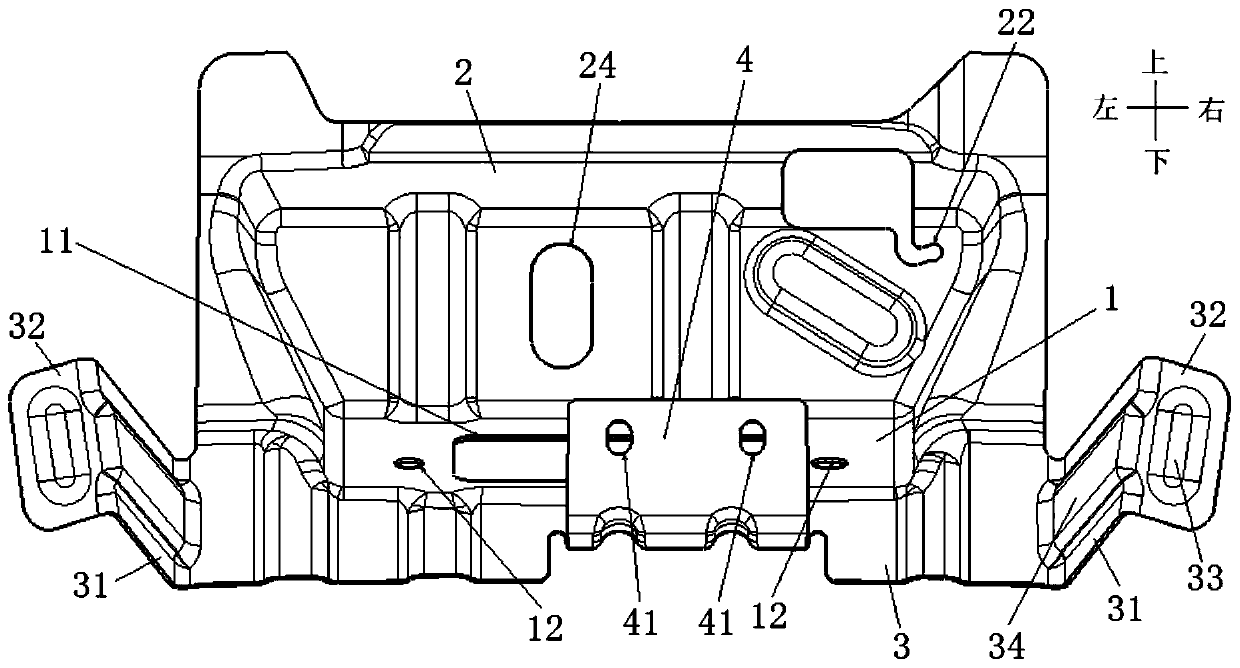

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings.

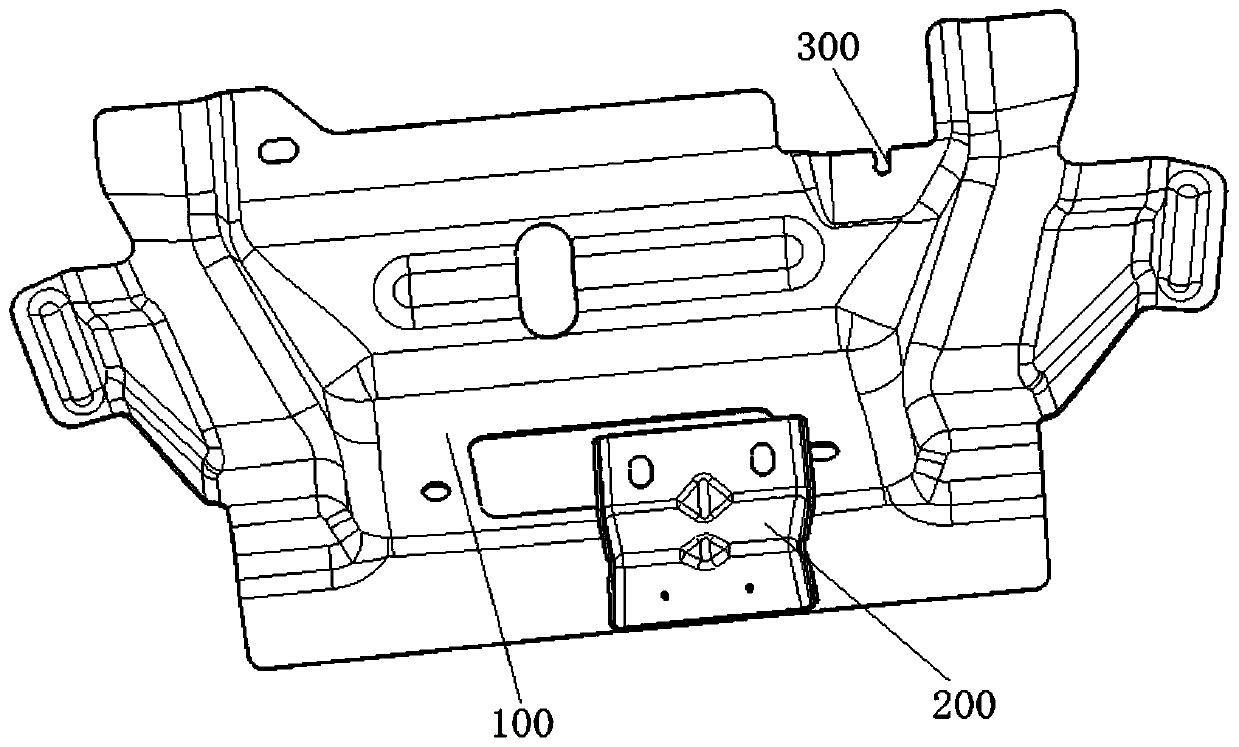

[0033] see Figure 2 to Figure 8 , the multifunctional back door lock reinforcement shown includes a bottom plate 1 on which a deadbolt through hole 11 and a back door lock installation hole 12 are provided for fixing the back door lock 8 . The front edge of the bottom plate 1 is provided with an upper plate 2 which is bent upwards and extended, and the rear edge of the bottom plate 1 is provided with a lower plate 3 which is bent and extended downwards. The left and right sides of the base plate 1 are respectively provided with first flanges 13 bent and extended to the left and right, and the front and rear edges of the first flanges 13 transition with the lower edge of the upper plate 2 and the upper edge of the lower plate 3 respectively. Connection; the first flange 13, the upper left end of the upper plate 2, the upper right end of the upper plate 2 and the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com