Wide hollow slab oblique section shearing resistance reinforcing method

A hollow slab, inclined section technology, applied in bridge reinforcement, bridge erection/assembly, bridge maintenance, etc., can solve problems such as inability to use reinforcement methods, limited operating space, and increased engineering costs, achieve good reinforcement effects, and reduce engineering costs. , The effect of enhancing the shear bearing capacity of the inclined section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

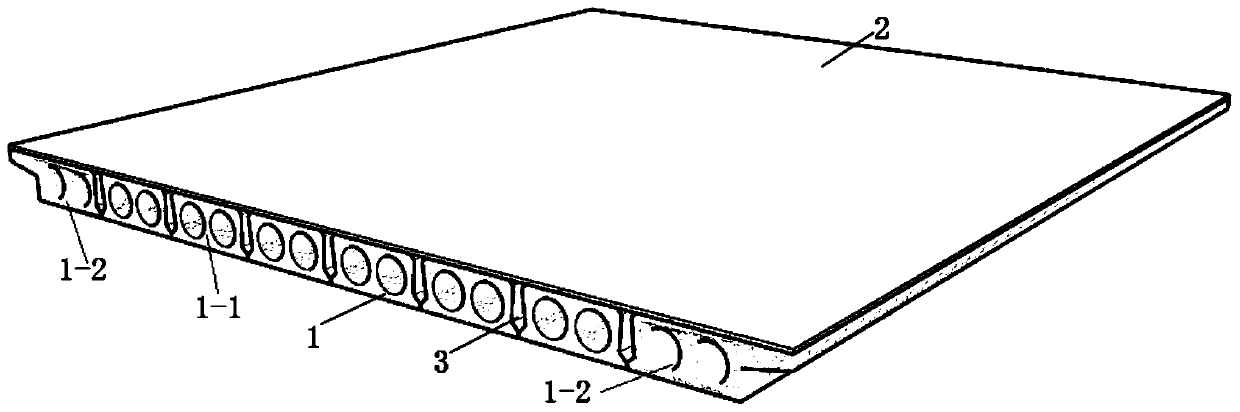

[0057] The specific steps of the shear reinforcement method for the oblique section of the wide hollow slab in this embodiment are as follows:

[0058] Step 1. Chisel away bridge deck pavement and wet joints;

[0059] The wet joints and concrete pavement of the old bridge were chiseled away, taking care to avoid damage to the beam body.

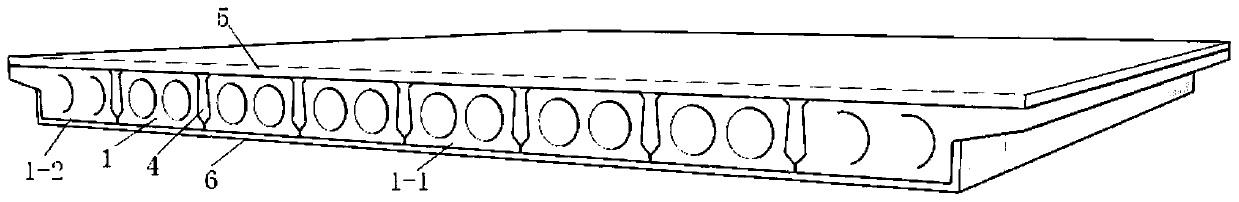

[0060] Step 2, chiseling and drilling the beam body;

[0061] And chiseling 0.5cm around the beam body to form an uneven surface; remove surface dust and other objects that affect concrete pouring. according to Figure 4(a) with 4(b) The drilling positions shown in the above are drilled with tools such as electric drills, and the diameter of the drilled holes is 2cm. If the steel bars in the concrete beam body are encountered during drilling, a certain distance can be properly avoided.

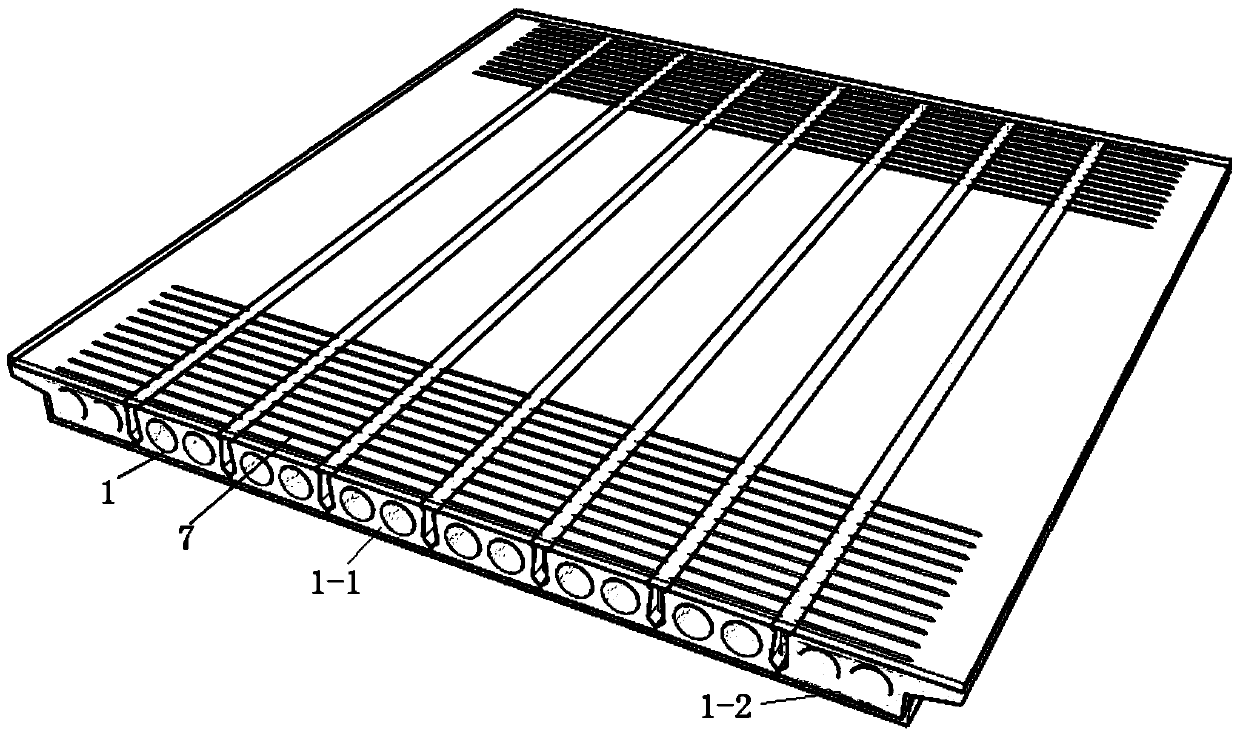

[0062] Step 3, placing steel bars and pouring wet joints;

[0063] The stirrups 7 are evenly distributed in the range from H to L / 4 from the beam end at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com