Fax machine adopting embedded heat-sensitive paper

A thermal paper, fax machine technology, applied in the direction of image communication, electrical components, etc., can solve the problems of paper lateral deviation, paper jam, paper feeding failure, etc., and achieve the effect of avoiding edge wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

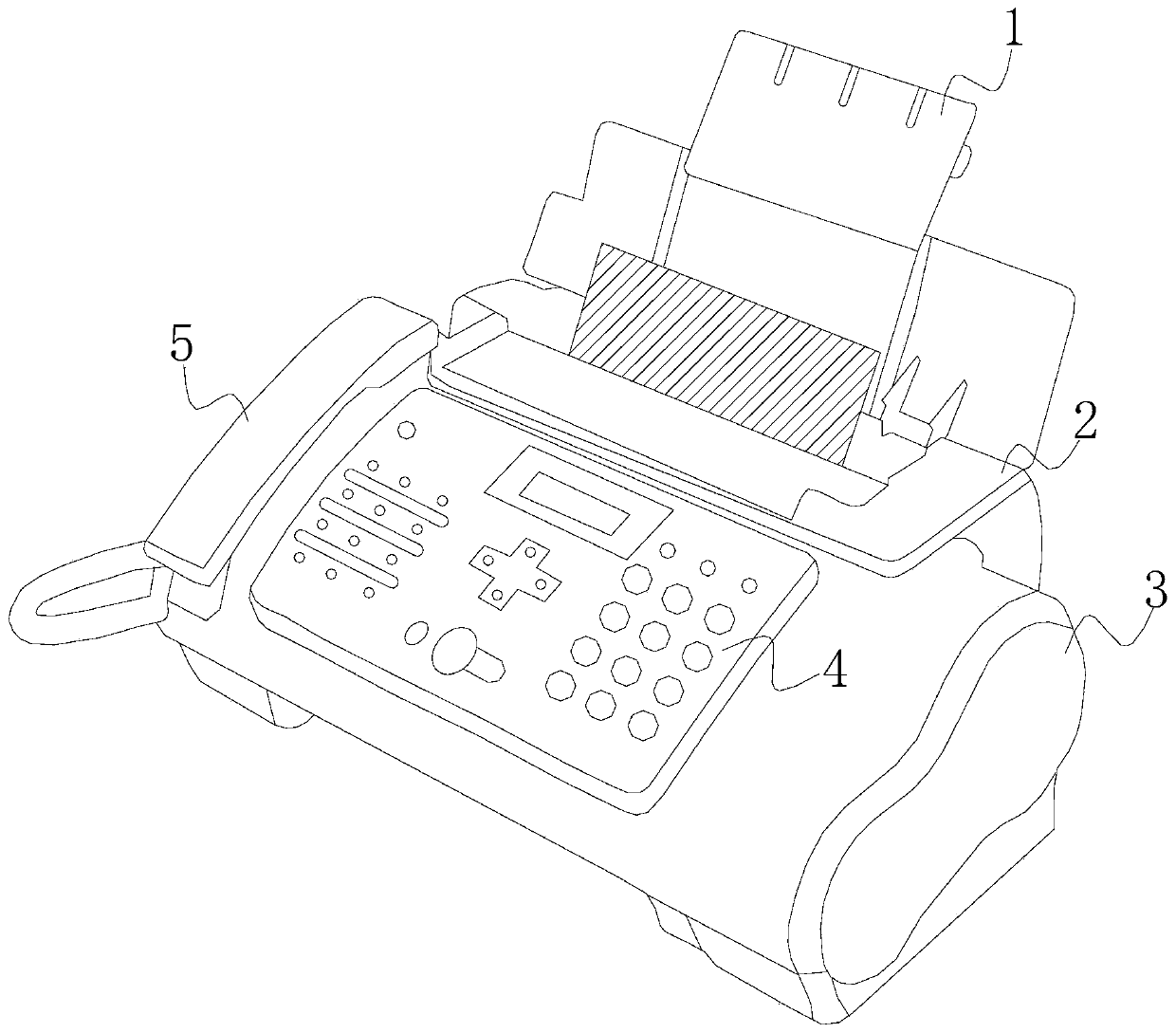

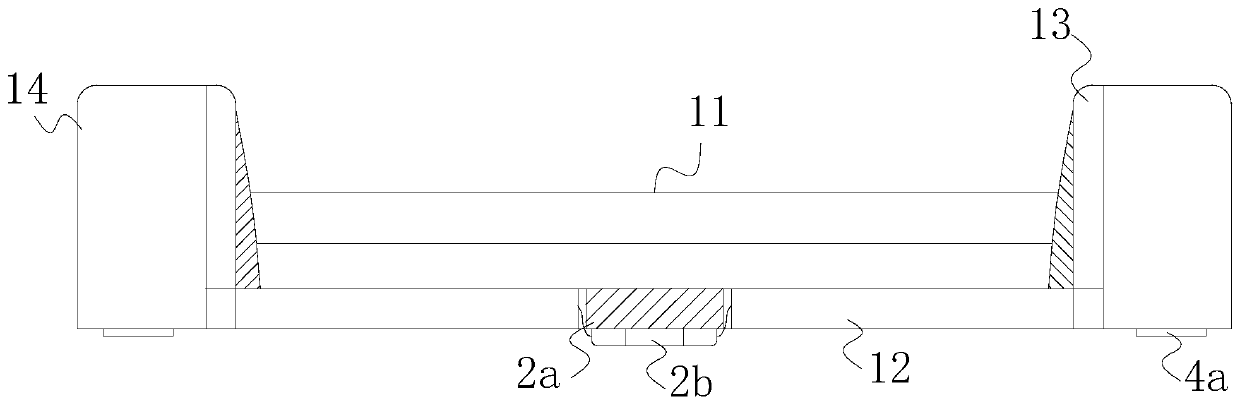

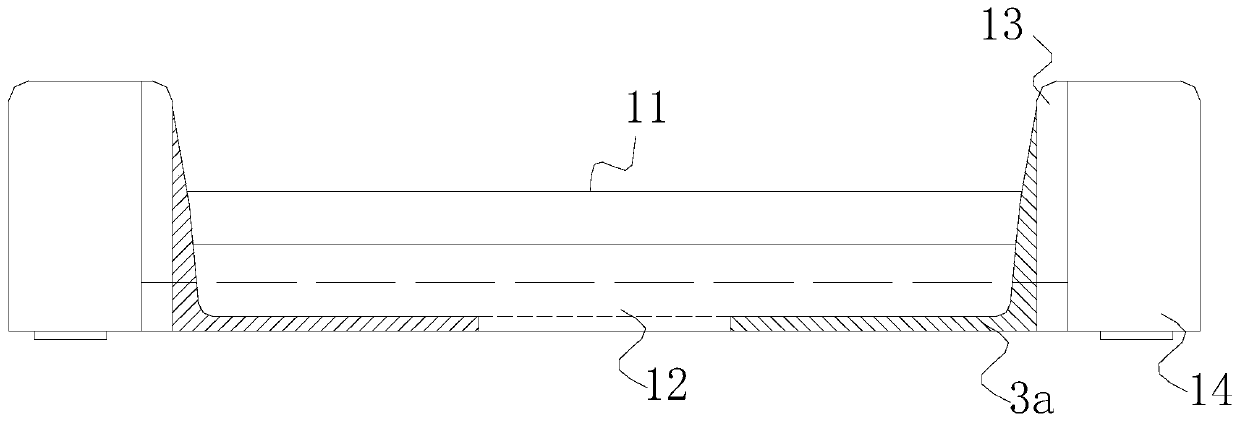

[0028] like Figure 1-Figure 7 As shown, the present invention provides an embedded heat-sensitive paper facsimile machine, its structure includes a paper feeding tray 1, a transmission port 2, a body 3, an operation panel 4, a telephone 5, and an input device is installed in the transmission port 2. Paper tray 1, described machine body 3 is provided with operation panel 4 and telephone 5, is provided with pickup roller 11, paper feed guide plate 12, paper guide plate 13, support seat 14 in described paper feed tray 1, described paper pickup The roller 11 is arranged on the inside position of the paper feed guide 12 which is located in the machine body 3, and the paper guide 13 is movably arranged on the left and right sides of the paper feed guide 12, and the described paper feed guide 12 is fixed in the machine body 3 by a support seat 14, and the The paper guide plate 13 has an L-shaped structure, its horizontal ends face each other, and a smooth surface 3a is provided on i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com