Parallel steel wire finished rope stretching device with anti-twisting structures and anti-twisting construction method thereof

A tensioning device and anti-rotation technology, which is applied in the field of prestressing, can solve the problems of damaged jacks, safety accidents, and personal injuries of operators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A parallel steel wire finished cable tensioning device with an anti-twist structure and its anti-twist construction method:

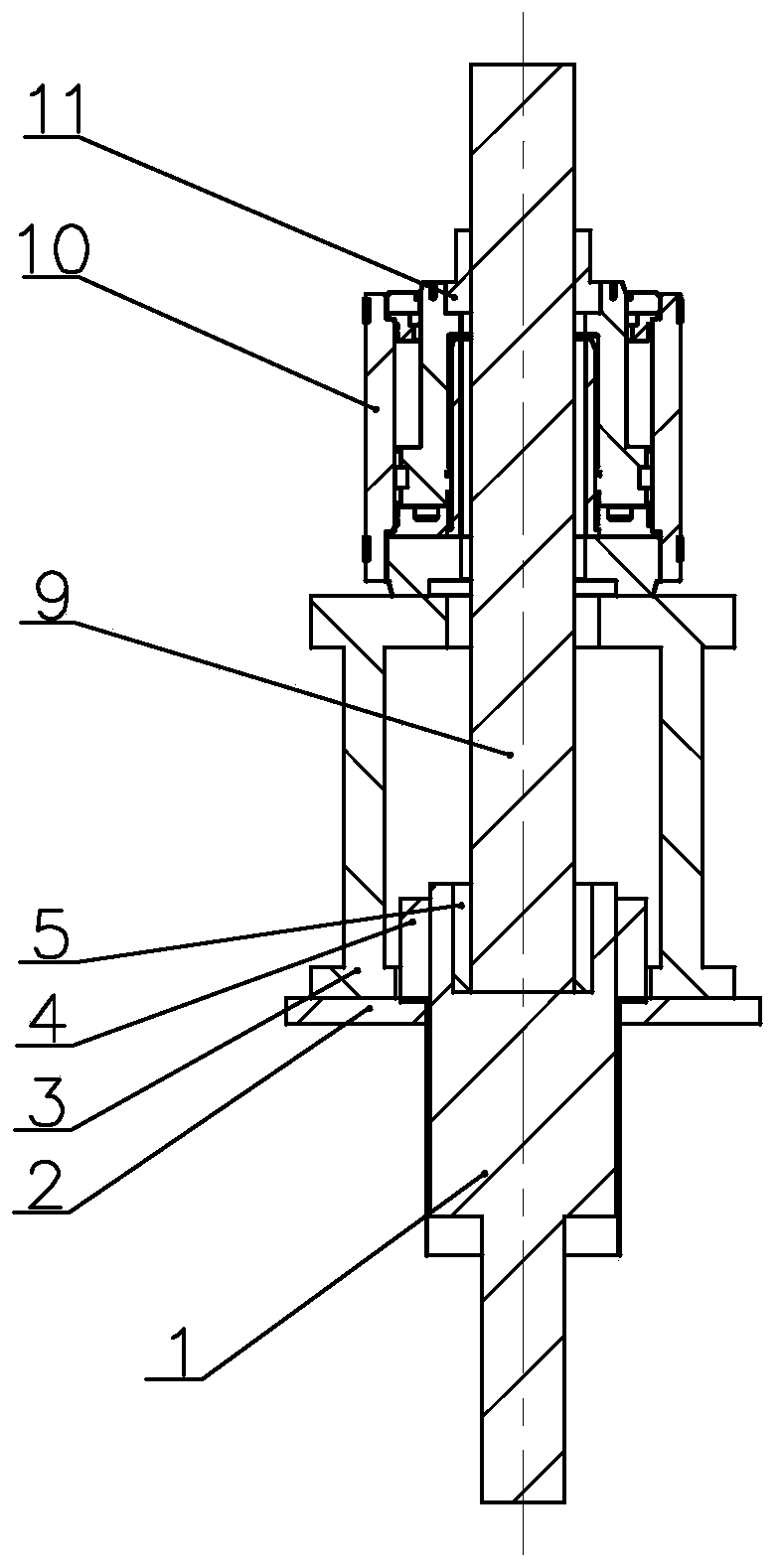

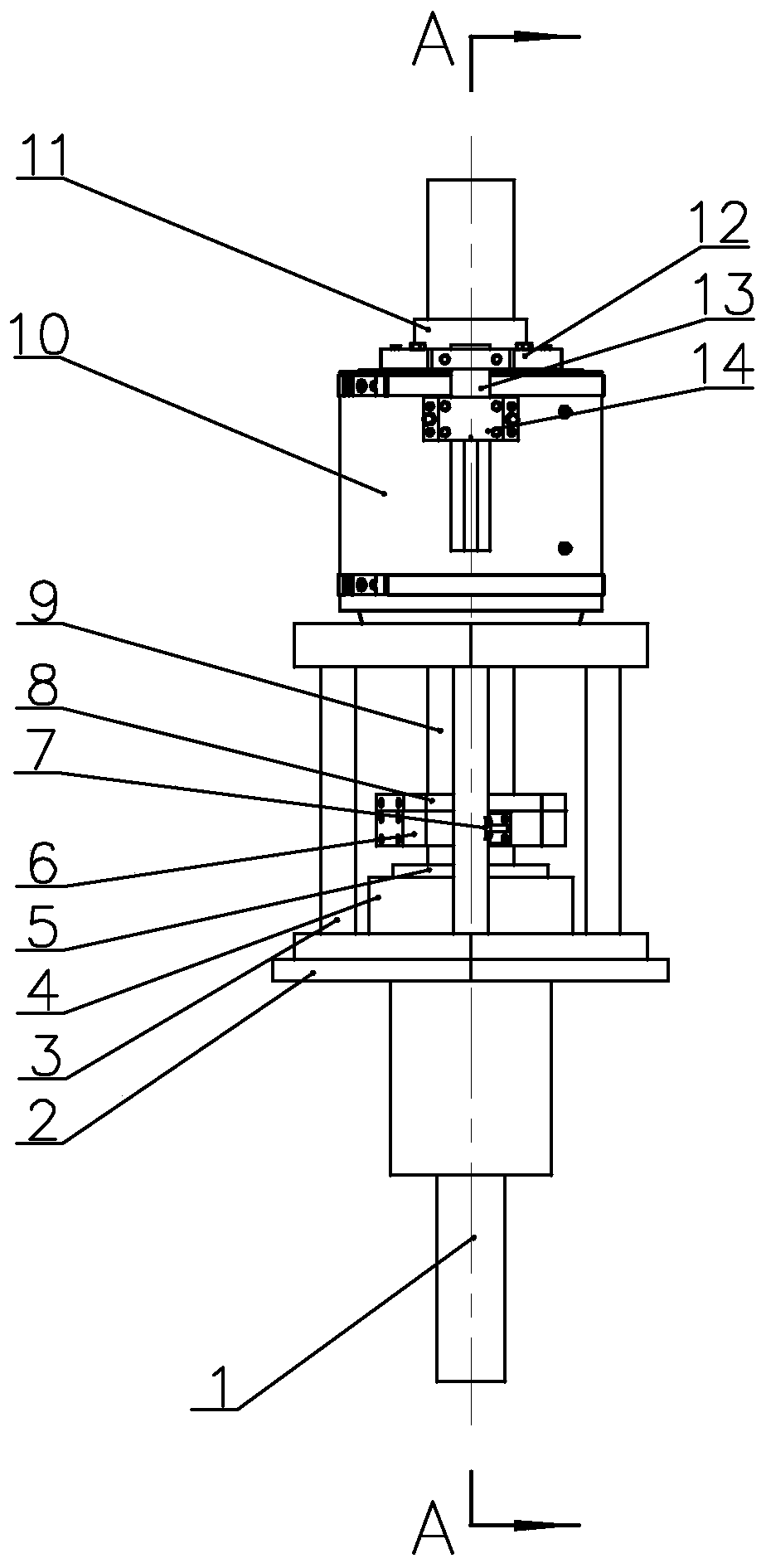

[0048] Such as Figure 1 ~ Figure 3 As shown, a kind of parallel steel wire finished cable tensioning device with anti-torsion structure of the present invention comprises cable anchor head 1, anchor plate 2, support foot 3, working nut 4, inner bushing 5, tension rod 9 , a tensioning device composed of a jack 10 and a tension nut 11, and two anti-rotation structures, anti-rotation structure I and anti-rotation structure II;

[0049] The anti-rotation structure I includes an anti-rotation body 12, an anti-rotation slider 13 and a guide seat 14. The anti-rotation body 12 is fixed on the piston ejection part of the jack 10 by screws, and the guide seat 14 is fixed on the cylinder body of the jack 10 by screws. Above, the anti-rotation slider 13 is located between the anti-rotation body 12 and the guide seat 14, and the anti-rotation slider 13 and t...

Embodiment 2

[0070] A kind of parallel steel wire finished cable tensioning device with anti-twist structure only installed with anti-twist structure I and its anti-twist construction method:

[0071] Such as Figure 4 ~ Figure 5 As shown, the basic structure of the "Parallel Steel Wire Finished Cable Tensioning Device with Anti-Twist Structure" of this embodiment is the same as that of Embodiment 1, and also includes a drag cable anchor head 1, an anchor pad 2, support feet 3, and working nuts. 4. A tensioning device consisting of an inner bushing 5, a tensioning rod 9, a jack 10, and a tensioning nut 11; the difference from Embodiment 1 is that this embodiment only has an anti-twist structure I, and the anti-twist structure The anti-rotation body 12 of I is fixed on the piston ejection part of the jack 10 by screws, the guide seat 14 is fixed on the cylinder body of the jack 10 by screws, and the anti-rotation slider 13 is located between the anti-rotation body 12 and the guide seat 14. ...

Embodiment 3

[0090] A tensioning device for finished parallel steel wire cable with an anti-twist structure and an anti-twist structure only installed with anti-twist structure II and its anti-twist construction method:

[0091] Such as Figure 6 ~ Figure 7 As shown, the basic structure of the "Parallel Steel Wire Finished Cable Tensioning Device with Anti-Twist Structure" of this embodiment is the same as that of Embodiment 1, and also includes a drag cable anchor head 1, an anchor pad 2, support feet 3, and working nuts. 4. A tensioning device consisting of an inner bushing 5, a tensioning rod 9, a jack 10, and a tensioning nut 11; the difference from Embodiment 1 is that this embodiment only has an anti-twist structure II, and the anti-twist structure II includes the Haval nut 6, the thin Haval nut 8 and the anti-rotation arm 7 arranged on the tension rod 9; The anti-rotation torque is greater than the torsional moment generated by the cable. One end of the anti-rotation arm 7 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com