Method for automatically replacing luminous paint bucket of cold spray marking machine

A technology of automatic replacement and luminous paint, which is applied in the direction of roads, buildings, road repairs, etc., and can solve problems such as replacement troubles and damages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

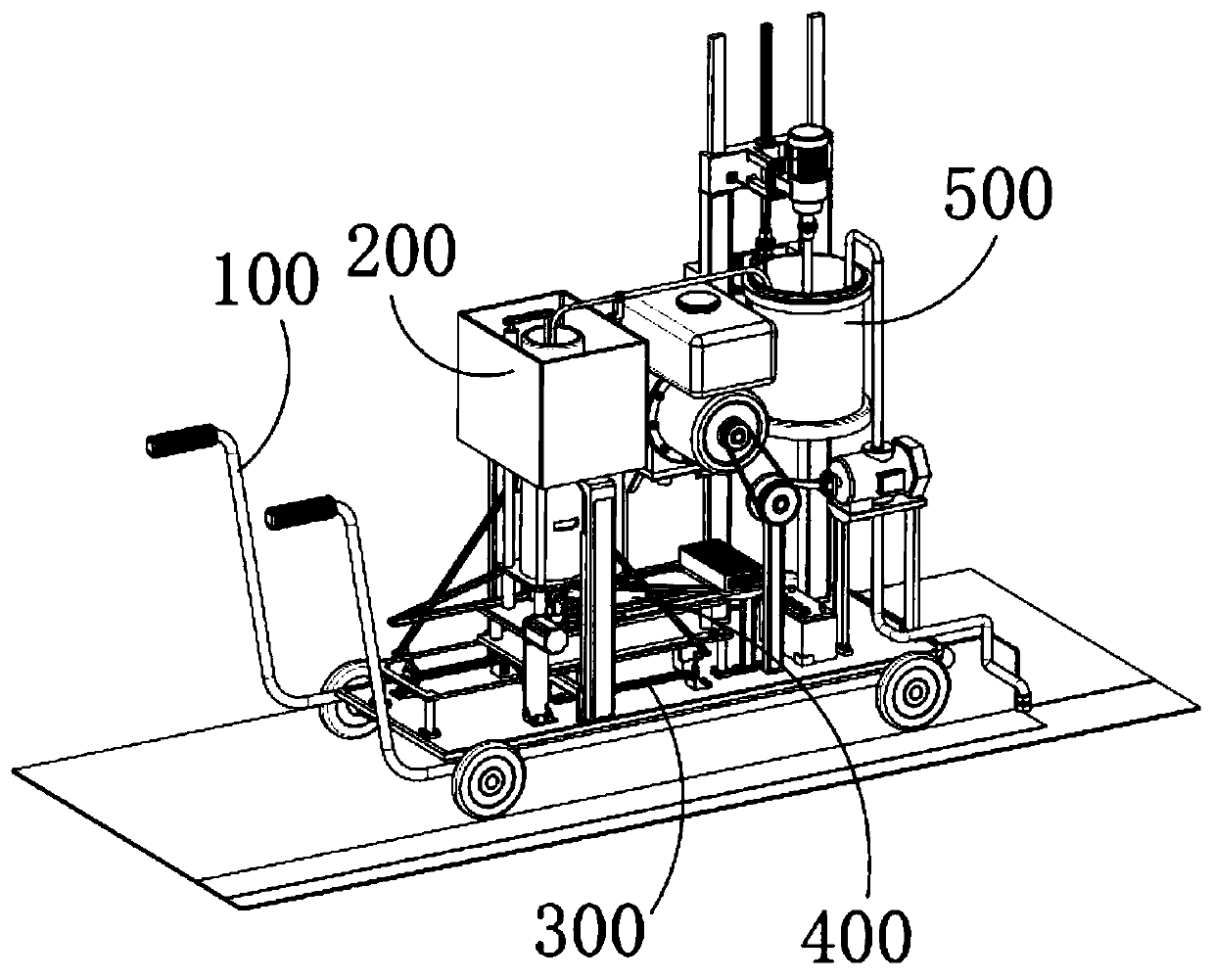

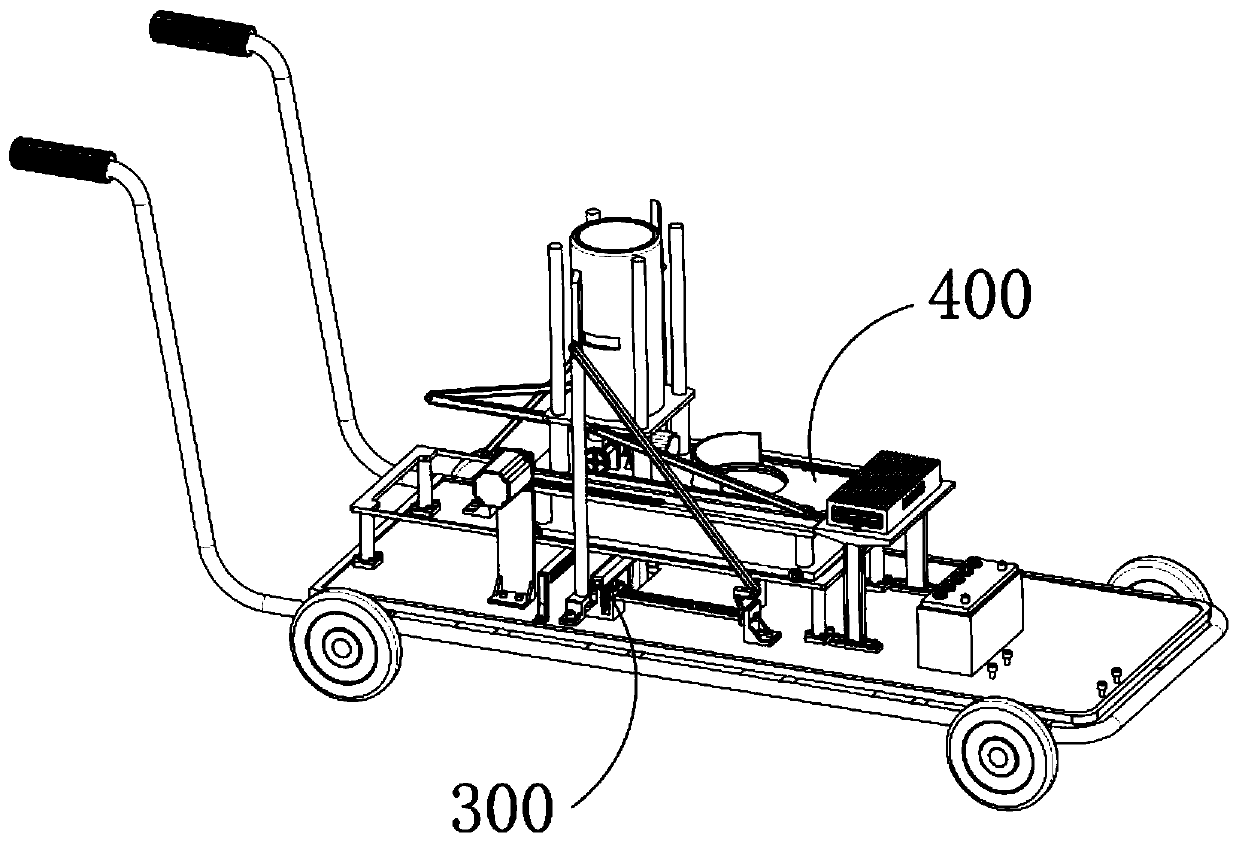

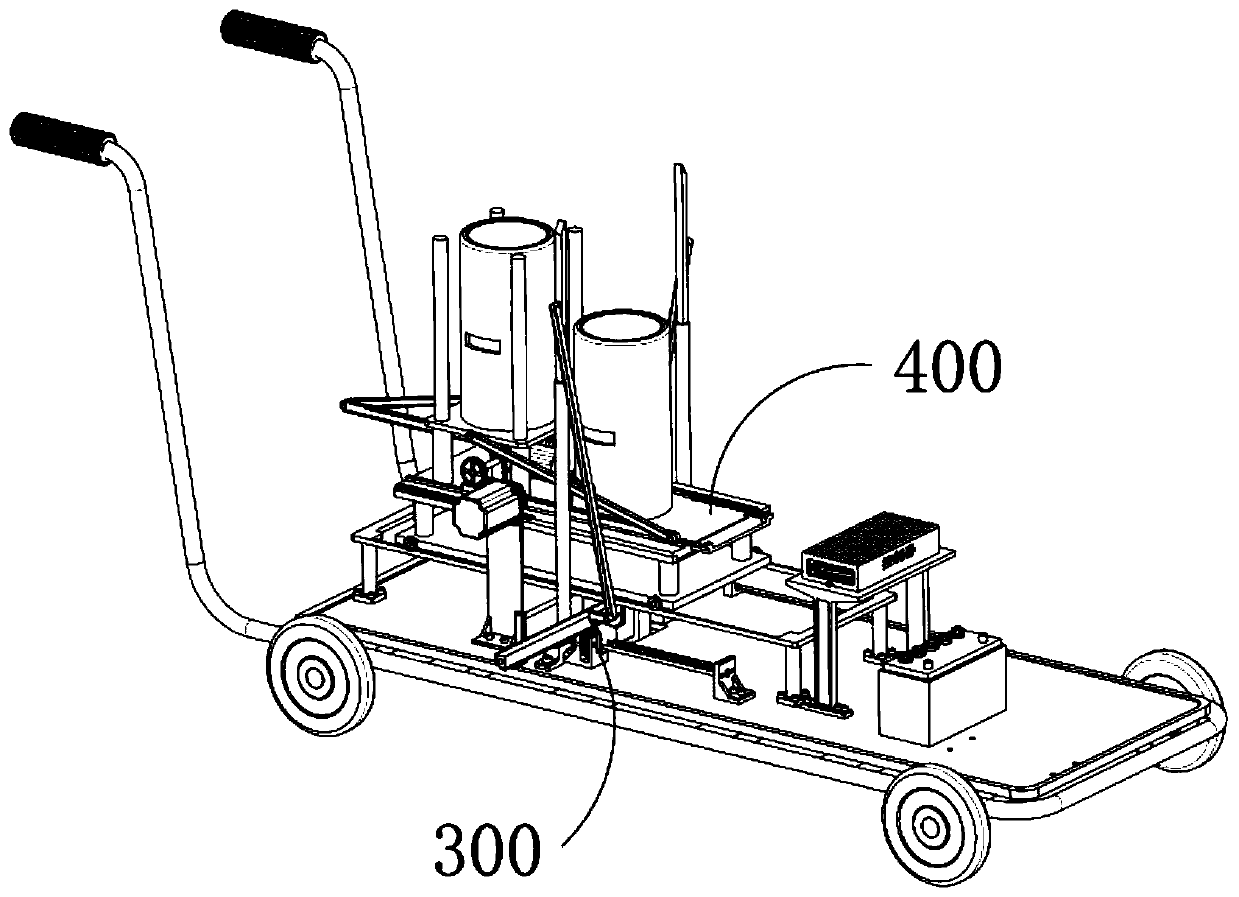

[0069] A method for automatically replacing luminous paint buckets on a cold spray marking machine, the steps of which are as follows:

[0070] S1: After the luminous paint in the luminous paint bucket mounted on the trolley body 100 clamped and installed by the paint bucket installation device 200 is used up, the canceling device 300 starts to operate;

[0071] The paint bucket installation device 200 includes a fixed cover and a paint bucket installation mechanism 210. The fixed cover is a rectangular shell structure with an open upper end and a closed lower end and is fixed on the trolley body 100. The paint bucket installation mechanism 210 is used to adopt a clip The luminous paint bucket is installed in the fixed cover in the holding installation method. The closed end of the fixed cover is provided with a lifting hole and a socket, and the lifting hole is located directly above the clamping installation area of the paint bucket installation mechanism 210. The paint buc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com