Efficient knitting machine

A knitting machine, high-efficiency technology, applied in knitting, textile and papermaking, crocheting, etc., can solve the problem of difficulty in training employees, and achieve the effect of high efficiency, improved product style, and large production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

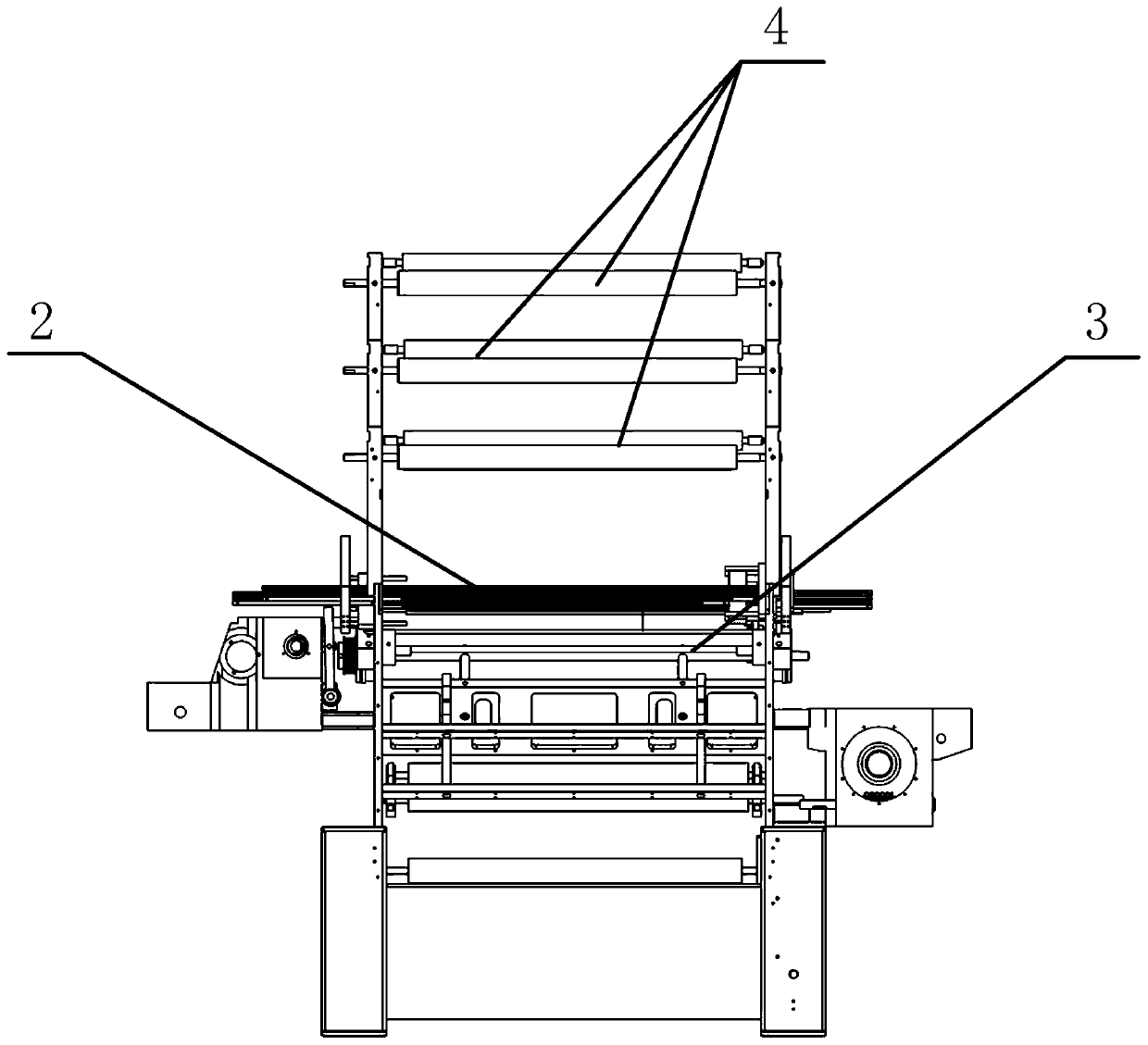

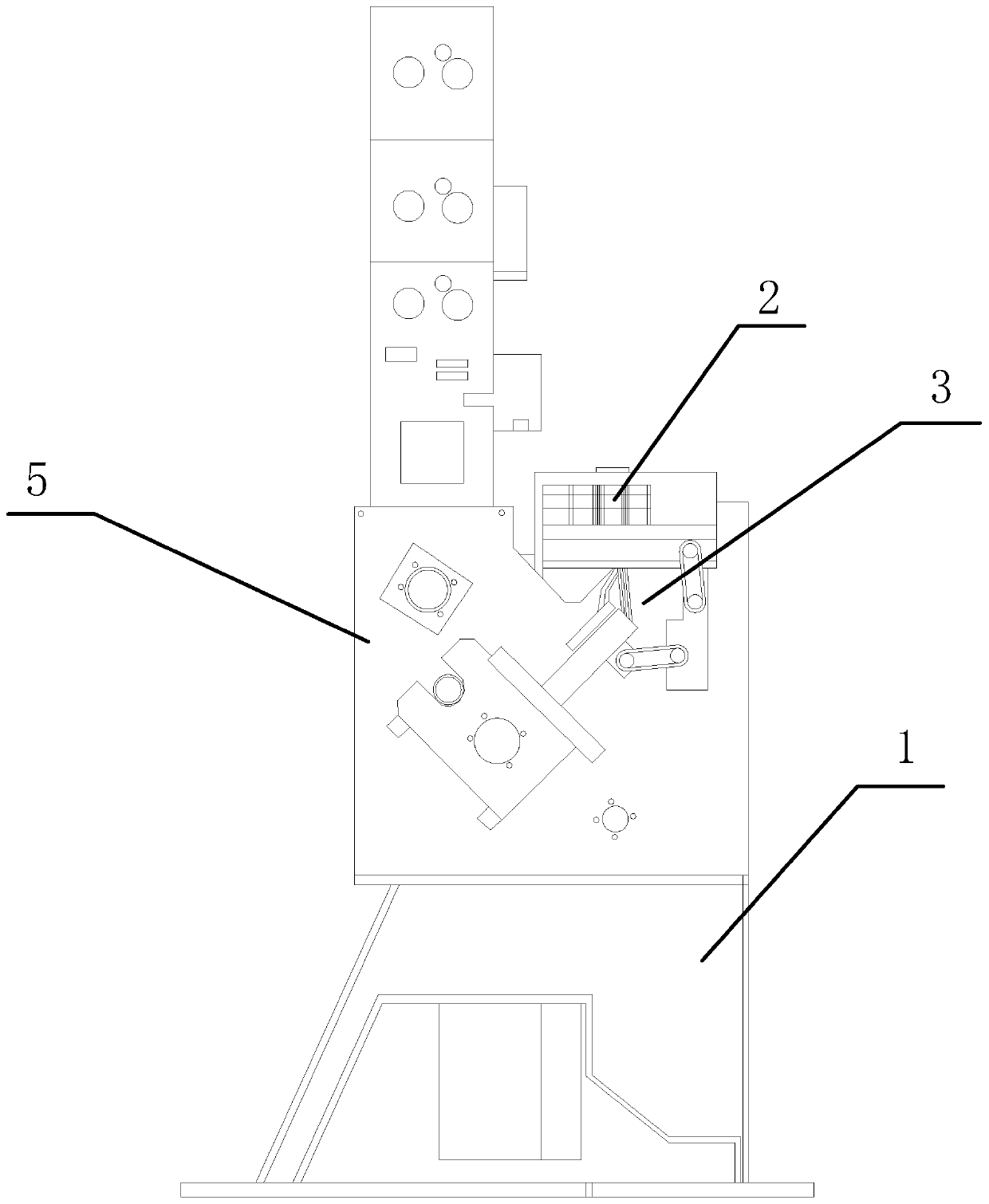

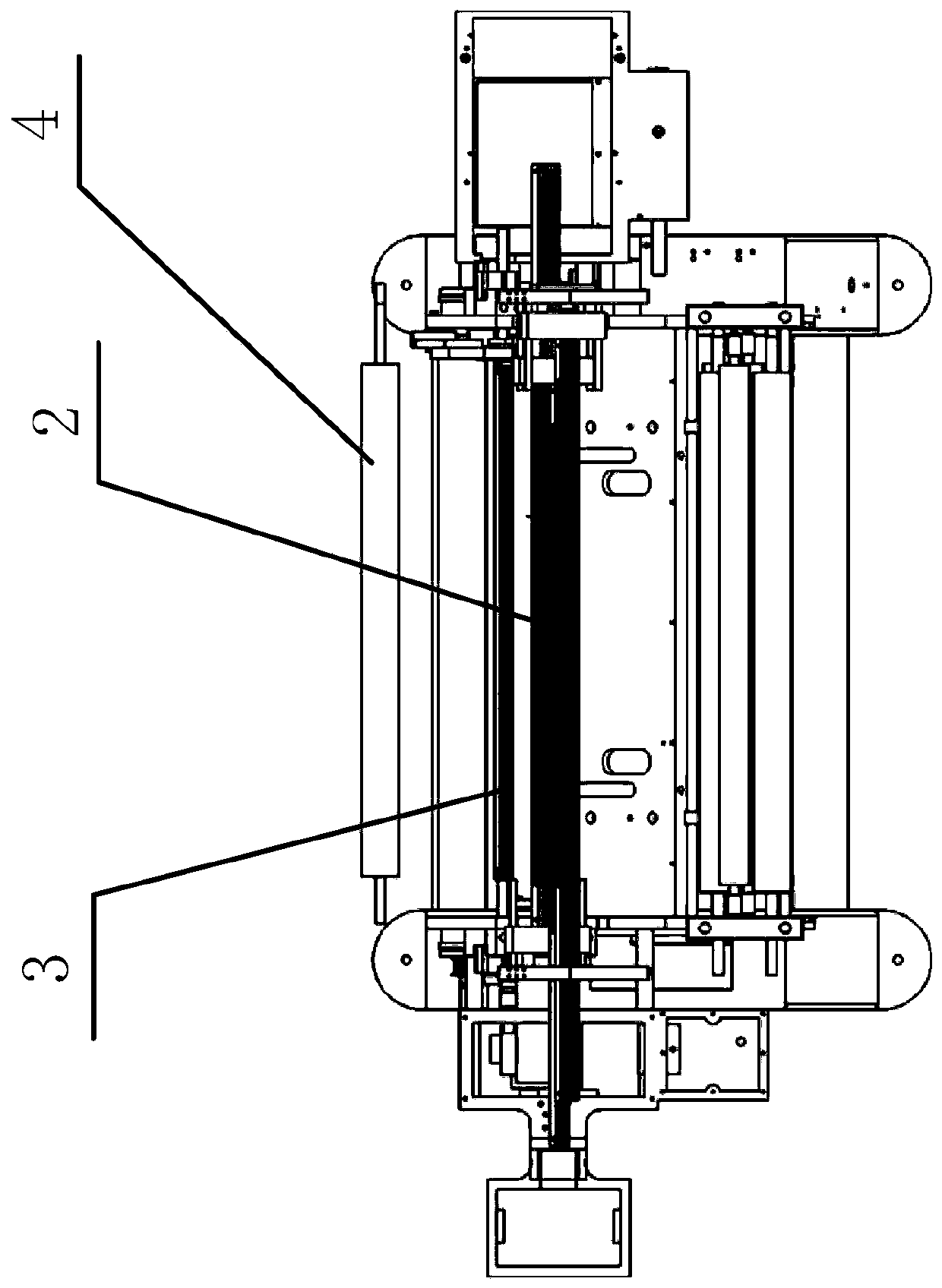

[0037] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, the knitting machine includes a frame 1, a palm drive system 2 and a needle bed system 3 arranged on the frame 1, and the needle bed system 3 includes a high-speed needle plate, an eye needle plate and a warp needle plate , the high-speed needle 31 on the high-speed needle needle board reciprocates in the direction of an inclination of 5 to 90° to the horizontal plane, the eye needle 32 on the eye needle needle board is parallel to the high-speed needle 31, and the eye needle 32 is parallel to it The corresponding high-speed needle 31 performs self-winding motion around the center;

[0038] The palm sheet trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com