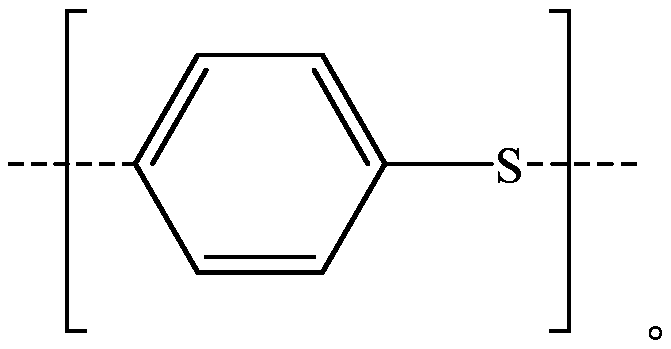

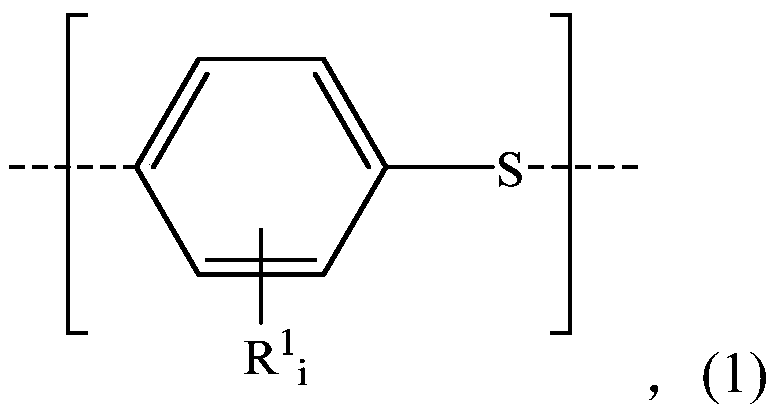

Polyphenylene sulfide polymer compositions and corresponding articles

A technology of polyphenylene sulfide and polymers, applied in the field of polyphenylene sulfide polymer compositions, capable of solving the problems of reduced strength of PPS polymer compositions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

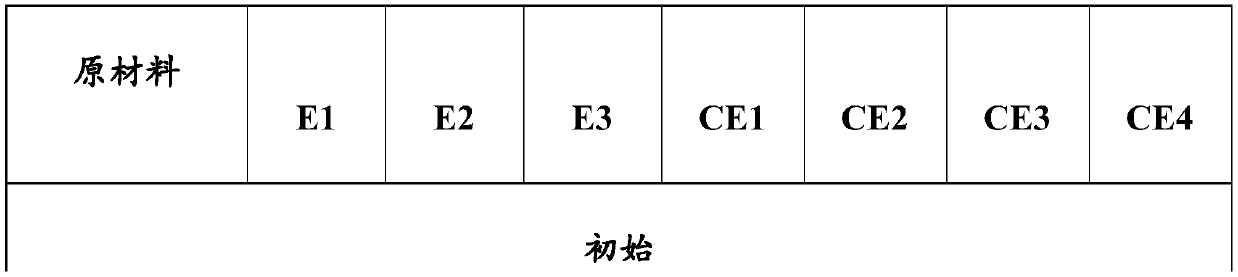

[0029] These examples demonstrate the high temperature water aging performance of the PPS polymer compositions described herein.

[0030] To demonstrate water aging performance, several sample compositions were made. Each composition contained a PPS polymer having a melt flow rate of 70 g / 10 min. ("Low MFR PPS") or 1500 g / 10 min. ("High MFR PPS"). Some compositions incorporate glass fibers ("GF"), or are available from Johns Manville as E-glass fiber ("E-GF 1") available from 770; E-glass fiber ("E-GF 2") available from Nippon Electric Glass America as ECS 03T779DE or E-CR Fiberglass (3B DS 8800-11P from 3B-The Fiberglass Company).

[0031] Boron concentration in glass fibers was measured using ICP-AES. For ICP-AES analysis, place a clean dry plastic container on the analytical balance and zero the balance. Weigh half to three gram samples and record the weight to 0.0001 g. The sample is then dissolved in hydrofluoric acid. The solution was neutralized with boron hydrox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com