Nuclear fuel pellet appearance surface defect online inspection system

A technology for inspecting systems and nuclear fuel, applied in nuclear engineering, nuclear power generation, nuclear reactor monitoring, etc., can solve problems such as difficulties and inconvenient detection, and achieve the effect of improving efficiency and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0031] Example

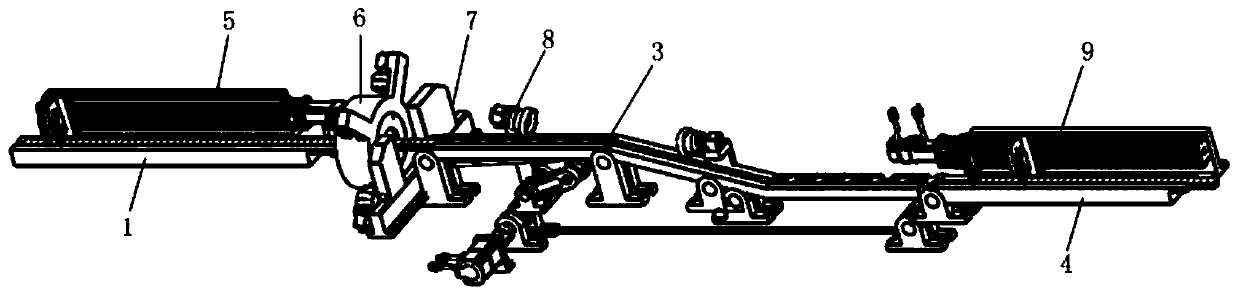

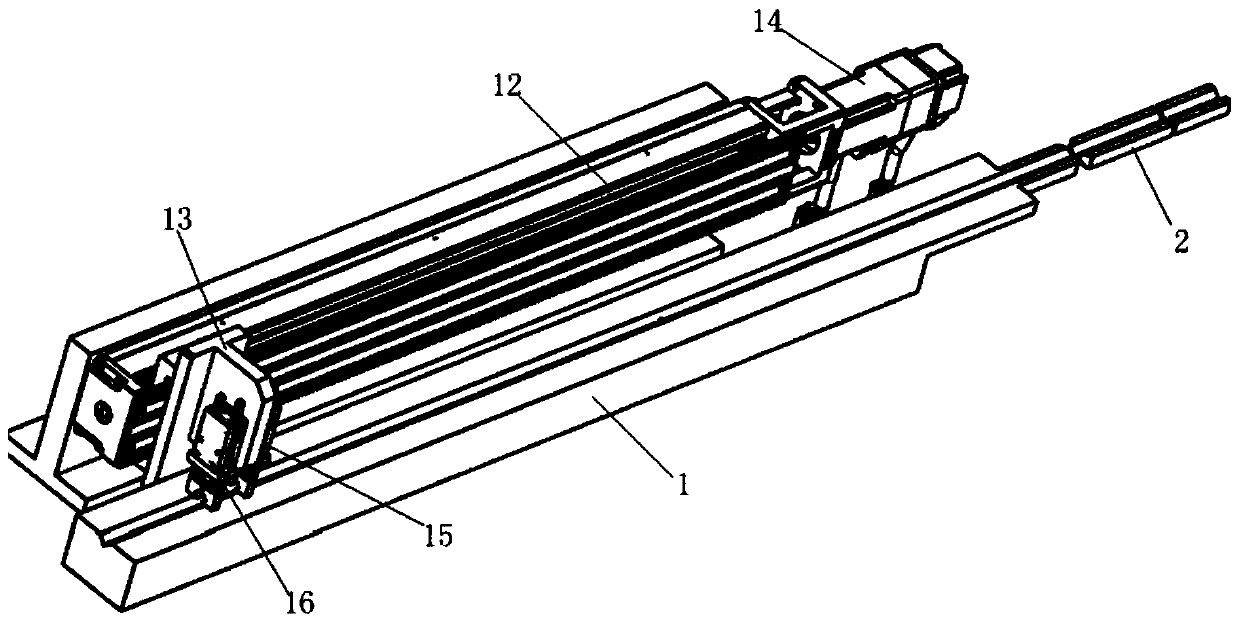

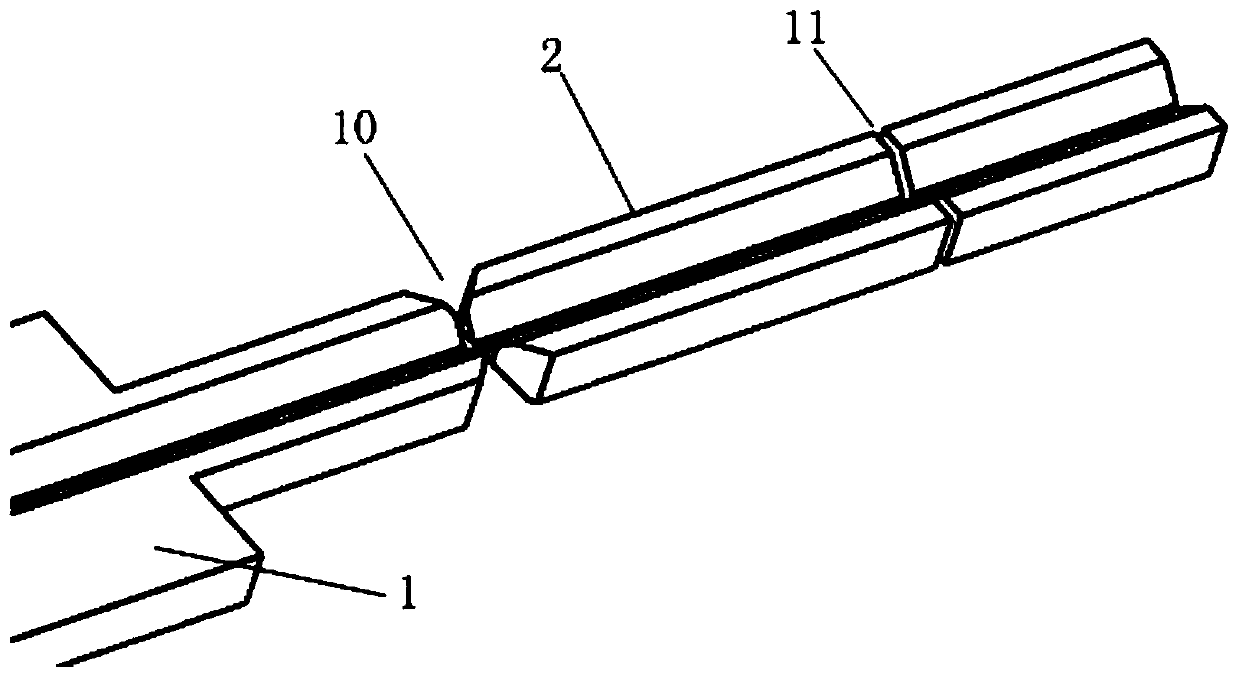

[0032] Such as Figure 1~7 As shown, the on-line inspection system for the appearance and surface defects of nuclear fuel pellets includes a feeding guide groove 1 butted with the production line of the previous process, a peripheral surface detection guide groove 2 and a double-row belt conveying mechanism 3 which are sequentially butted after the feeding guide groove. , Discharge guide groove 4, the feeding pushing mechanism 5 corresponding to the feeding guide groove, the peripheral surface detection assembly 6 and the diameter detection assembly 7 corresponding to the peripheral surface detection guide groove, and the end surface detection corresponding to the double-row belt conveying mechanism. The assembly 8 and the discharging pushing mechanism 9 corresponding to the discharging guide groove, wherein the double-row belt conveying mechanism is provided with a slope, and the end face detection assembly faces the passing nuclear fuel core at the convex corner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com