Self-cleaning multistage depressurization adjusting valve

A depressurizing, self-cleaning technology, applied in sliding valves, valve details, valve devices, etc., can solve problems such as blockages that cannot be automatically removed, reduced valve performance, and many bending times, and achieves compact structure, improved performance and The effect of service life and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

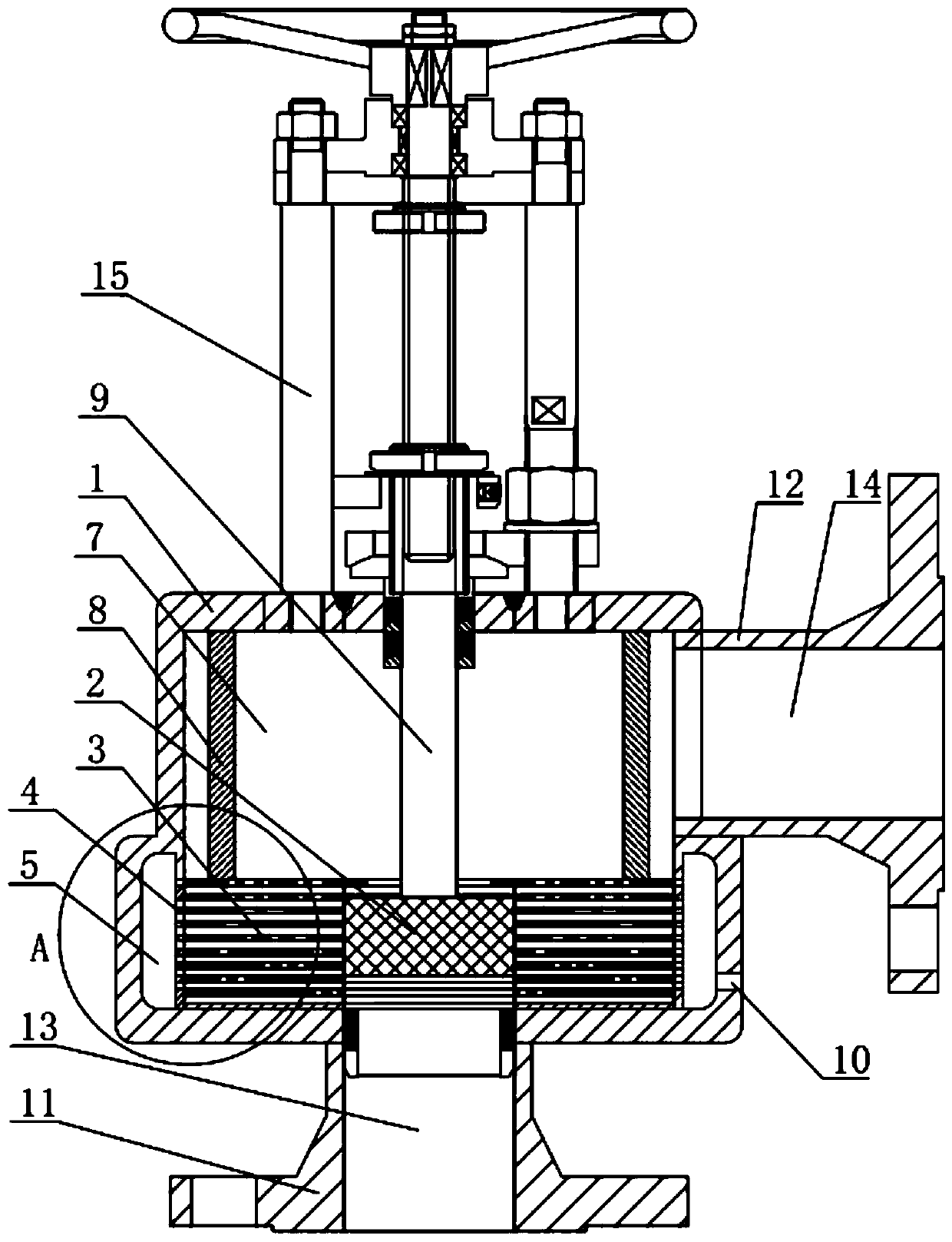

[0035] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

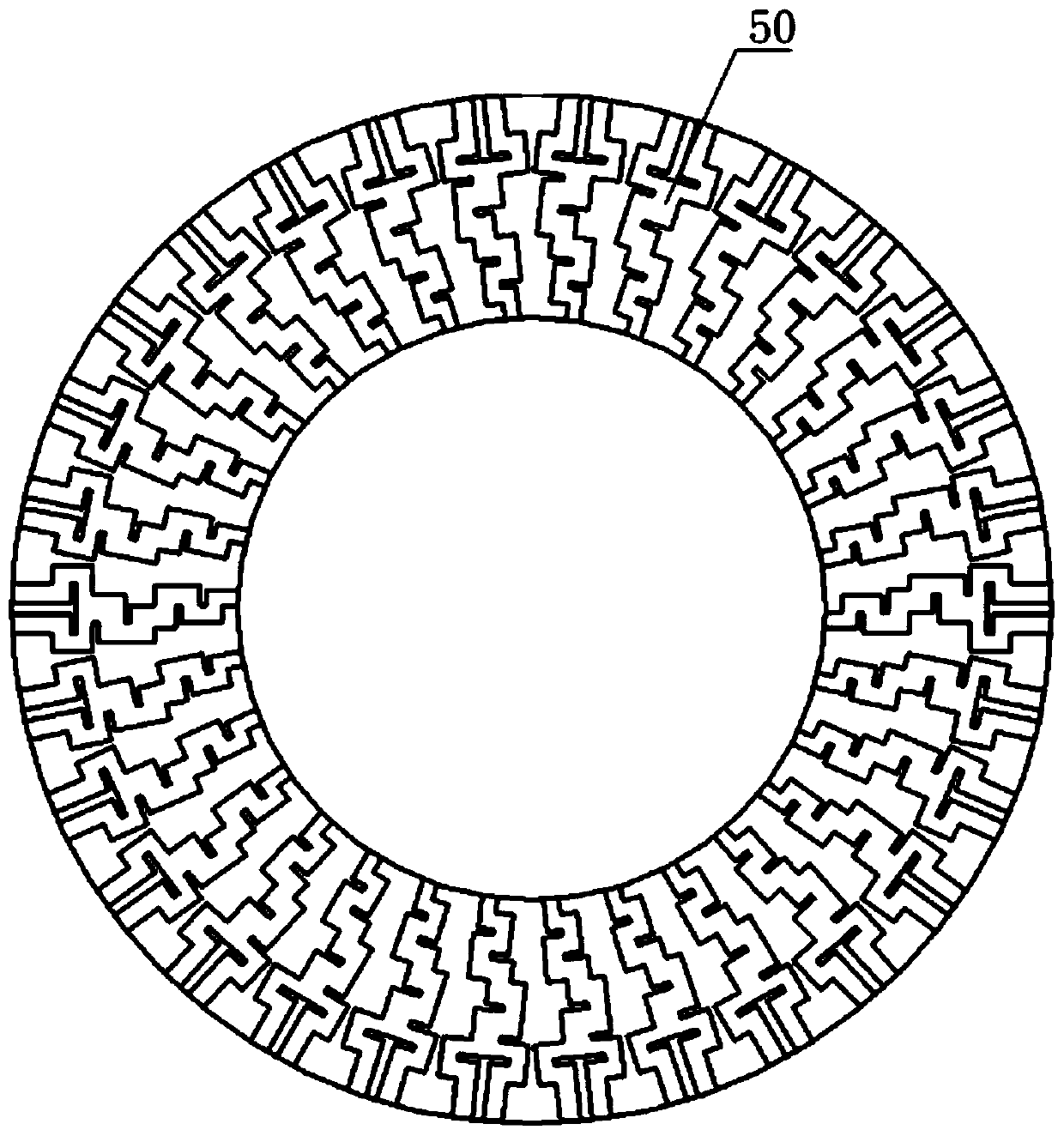

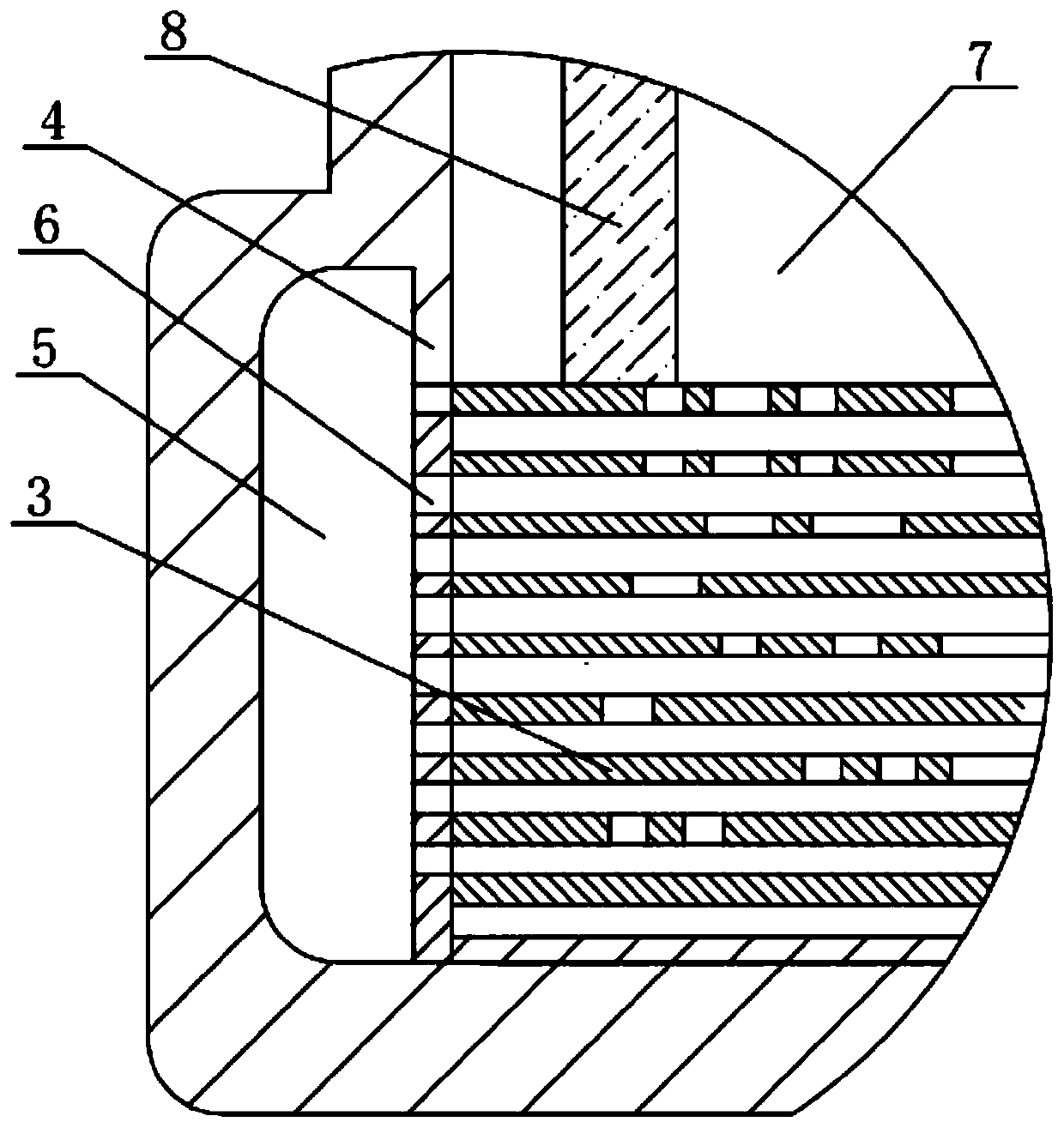

[0036] Such as figure 2 and image 3 As shown, the self-cleaning multi-stage pressure-reducing regulating valve of this embodiment includes a hollow valve body 1, a sleeve 3 is installed on the inner bottom surface of the valve body 1, and a valve body 1 located outside the outer peripheral surface of the sleeve 3 is provided with Interlayer 4, a sewage discharge chamber 5 is formed between the interlayer 4 and the inner wall of the valve body 1, and a sewage discharge groove 6 is arranged on the interlayer 4; a valve core 2 is installed in the middle of the sleeve 3;

[0037] The structure of the sleeve 3 is as follows: it includes multiple discs 32 stacked at intervals, each disc 32 has a plurality of through holes 35 for fluid flow;

[0038] The valve core 2 drives the sleeve 3 to move, so that the discs 32 or the intervals between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com