Extension tube for vacuum cleaner

A vacuum cleaner and extension tube technology, which is applied in the field of extension tubes for vacuum cleaners, can solve the problems of dead corners of hygiene, heavy extension rods, poor appearance, etc., and achieves the effects of reducing the difficulty of injection molding, facilitating rapid passage, and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

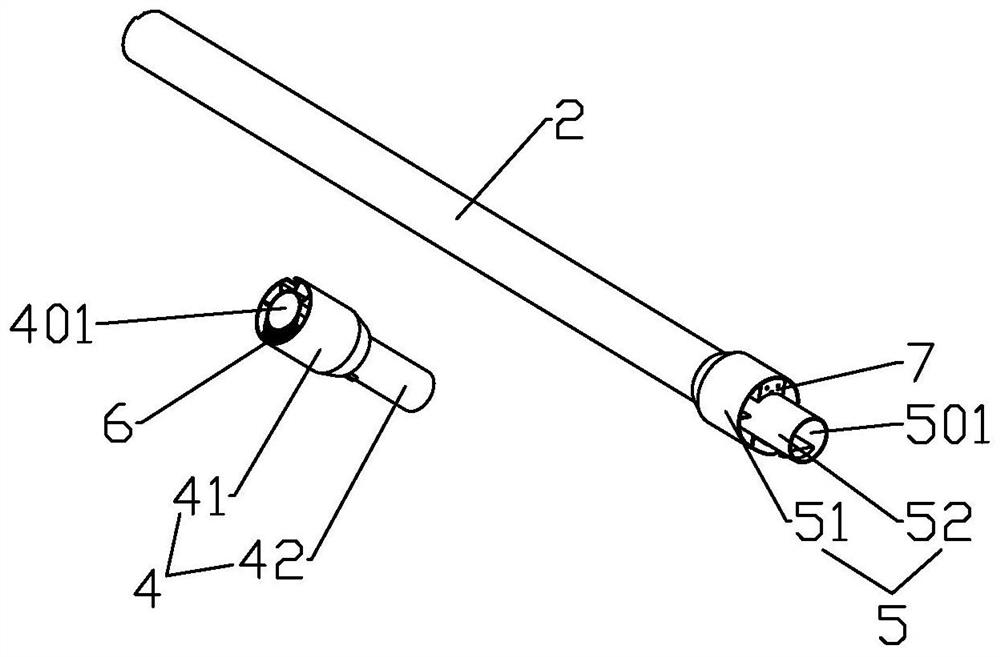

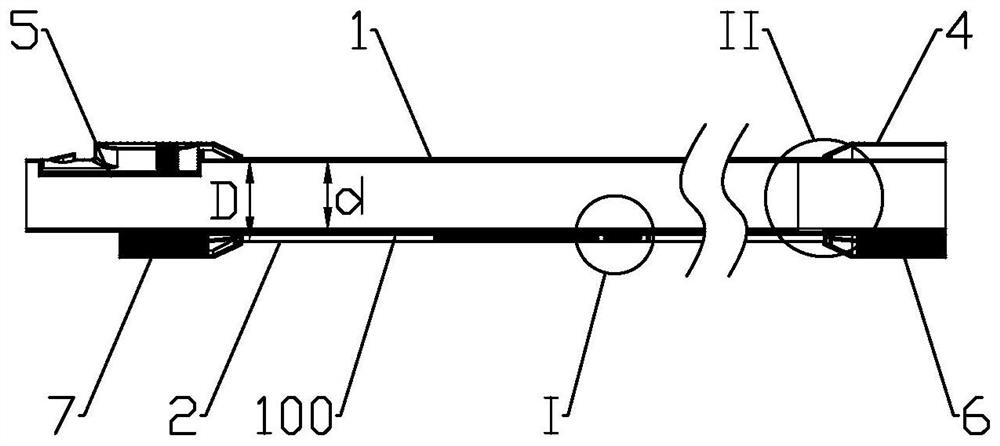

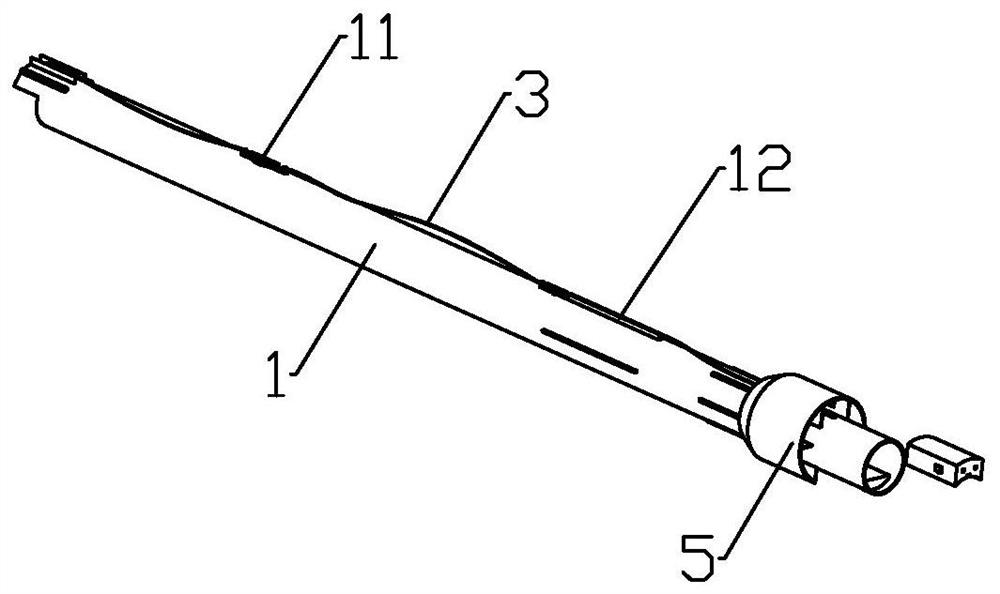

[0022] The invention provides an extension tube for a vacuum cleaner, which combines figure 1 , 2 See, including the inner tube 1, the outer tube 2 and the electric wire 3, the outer tube 2 is set on the outside of the inner tube 1, and the two ends of the inner tube 1 are respectively provided with a first connector 4 and a second connector 5, the first connector 4 and at least one of the second connector 5 and the inner tube 1 or the outer tube 2 are separate structural members, the first connector 4 includes a first communication hole 401 that is docked with the inner tube 1, and the hole 401 is connected to the inner cavity of the inner tube 1 The second connection head 5 includes a second communication hole 501 that is docked with the inner tube 1. The hole 501 is also connected with the inner cavity of the inner tube 1. The first connection head 4 and the second connection head 5 are provided with a The tube 2 makes the outer tube 2 limit structure of the routing channe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com