Multi-module variable-frequency heating device

A heating device and multi-module technology, applied in the direction of electric heating devices, devices that make medicines into special physical or ingestible forms, electrical components, etc., can solve problems such as easy electric shock, complicated power adjustment, unreliable mechanical structure, etc., to achieve High safety, simple structure and high decoction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained in conjunction with specific drawings.

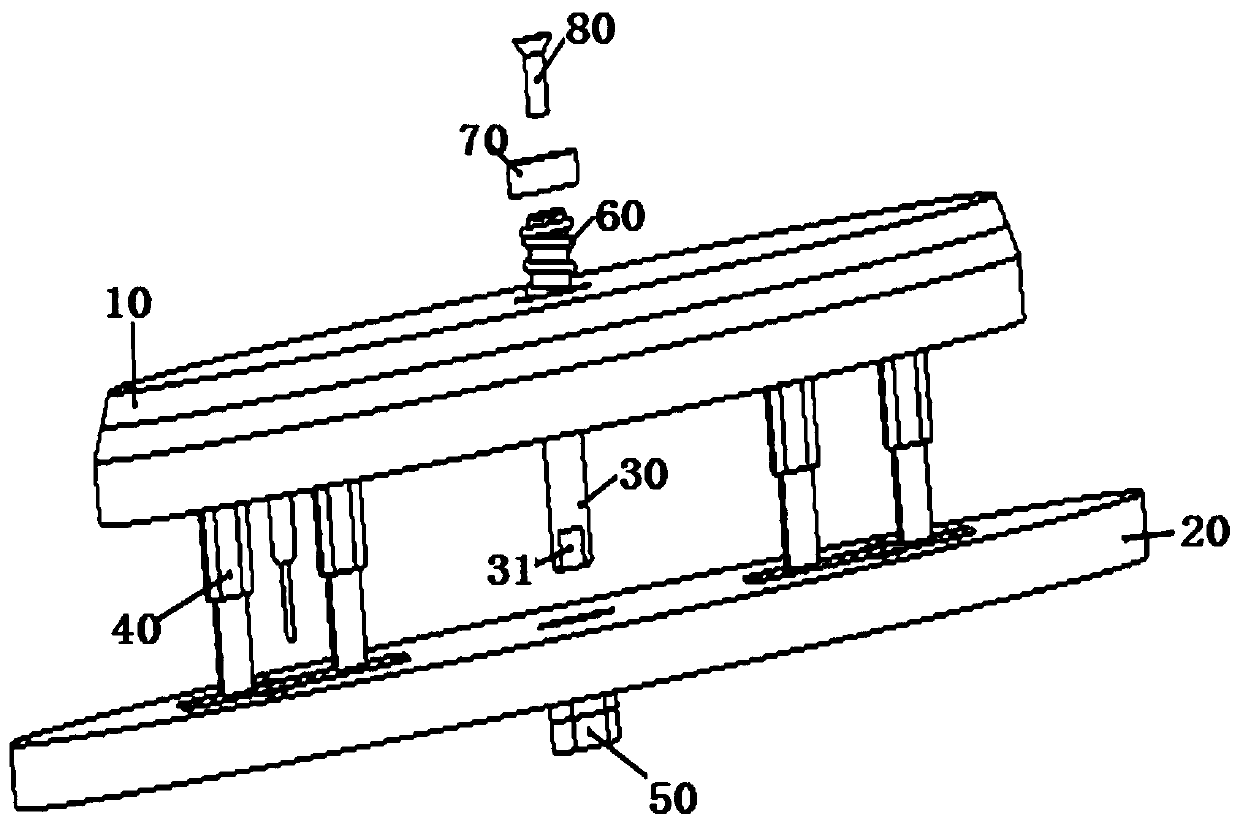

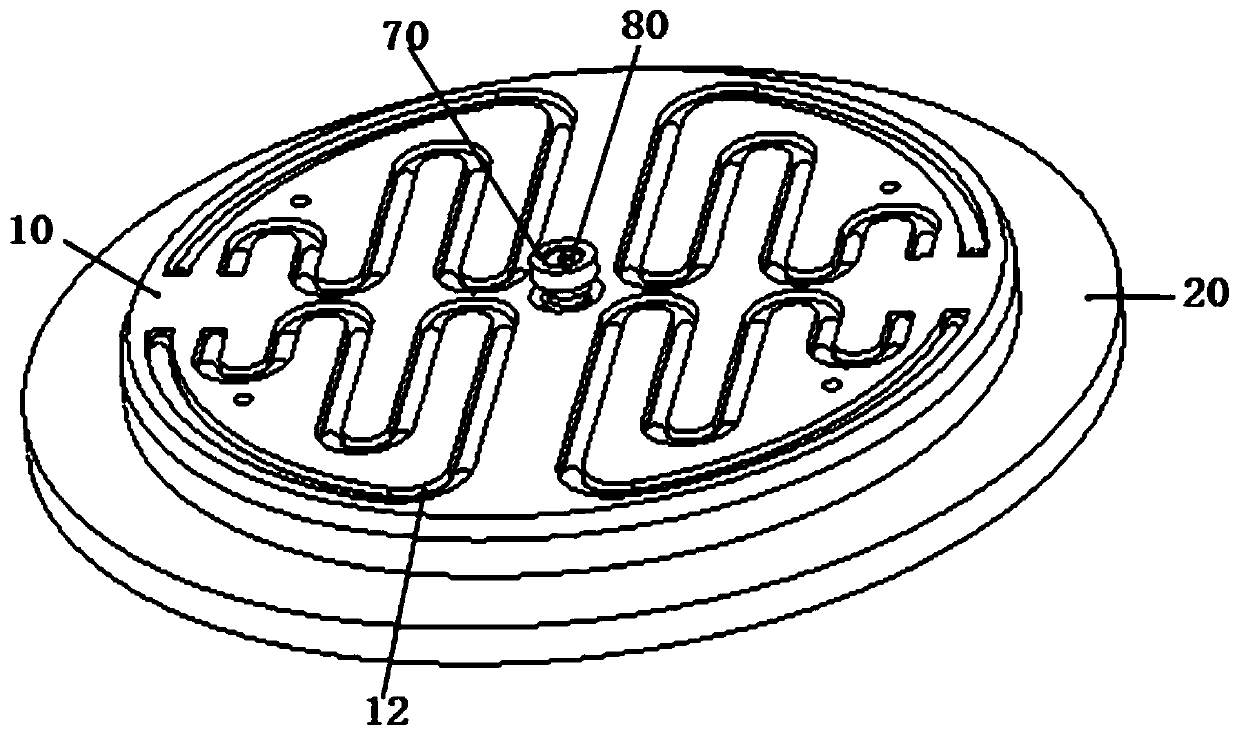

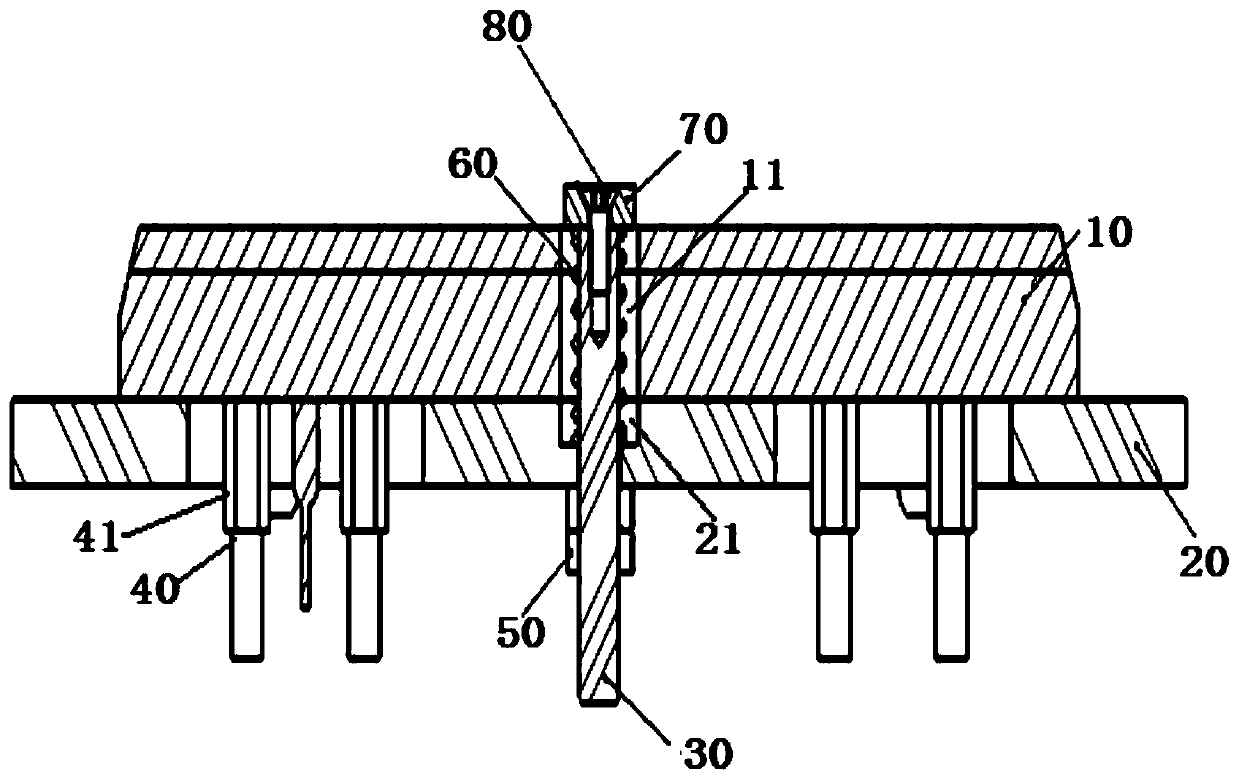

[0023] See Figure 1 to Figure 3 As shown, the present invention discloses a multi-module frequency conversion heating device. The heating device includes a heating plate 10, a heat insulation plate 20, and a stroke guide 30.

[0024] The heating plate 10 is circular in shape and made of aluminum casting, with strong corrosion resistance and high strength; the middle of the heating plate 10 is provided with a through hole 11 that penetrates the heating plate body, and the upper surface of the heating plate 10 is provided with at least one recess Groove 12, there are 4 grooves 12 in the present invention, and they are evenly distributed on the upper surface of the heating plate 10. Each groove 12 is encapsulated with heating wires (not shown in the figure), and 4 he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com