Petroleum mass flow detection system and detection method thereof

A mass flow and detection system technology, which is applied in the direction of mass flow measurement devices, measurement devices, material inspection products, etc., can solve the problems of inaccurate measurement of sample oil flow, uneven inner wall of pipeline, uneven flow velocity, etc., and improve detection accuracy and accuracy, convenient detection, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

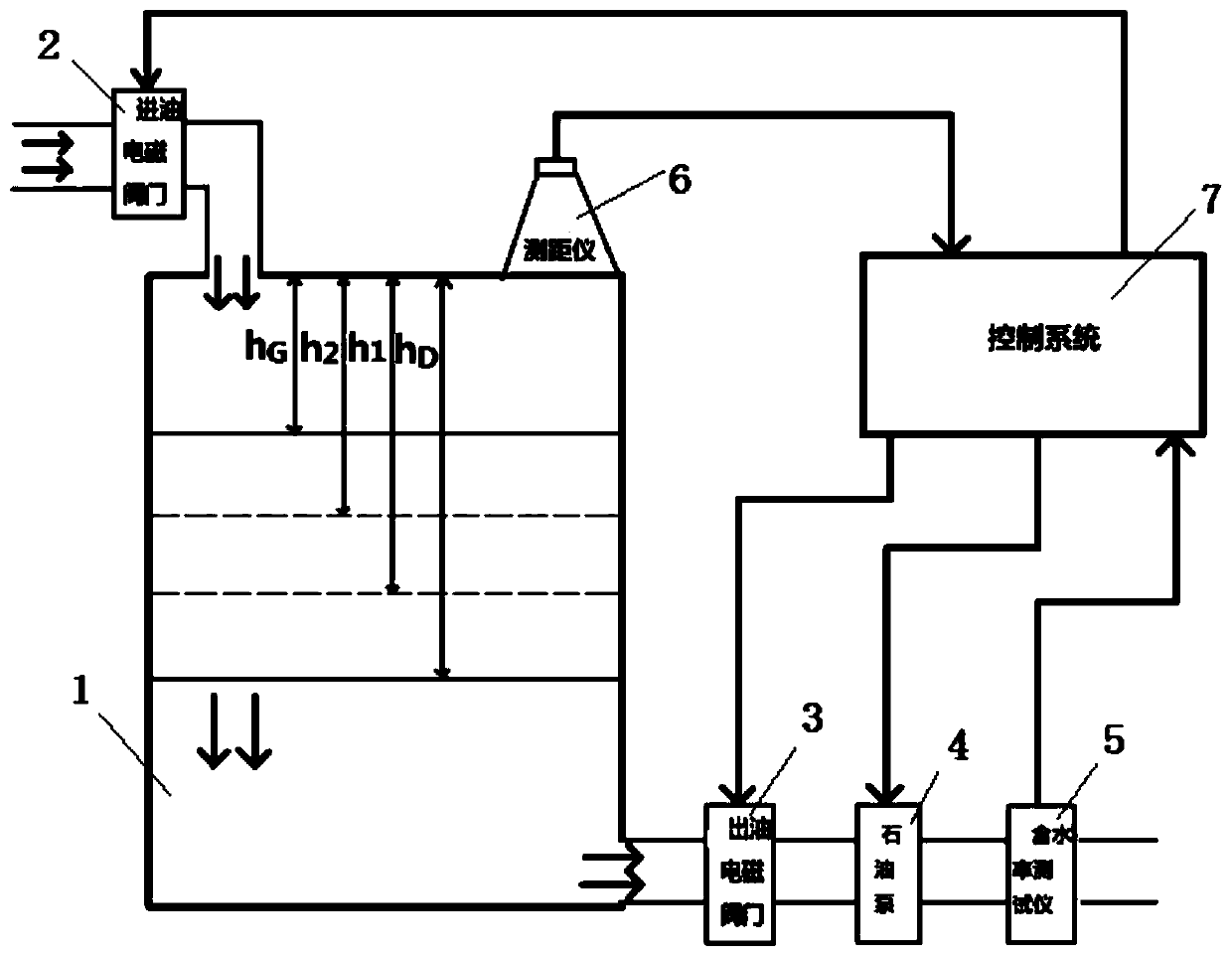

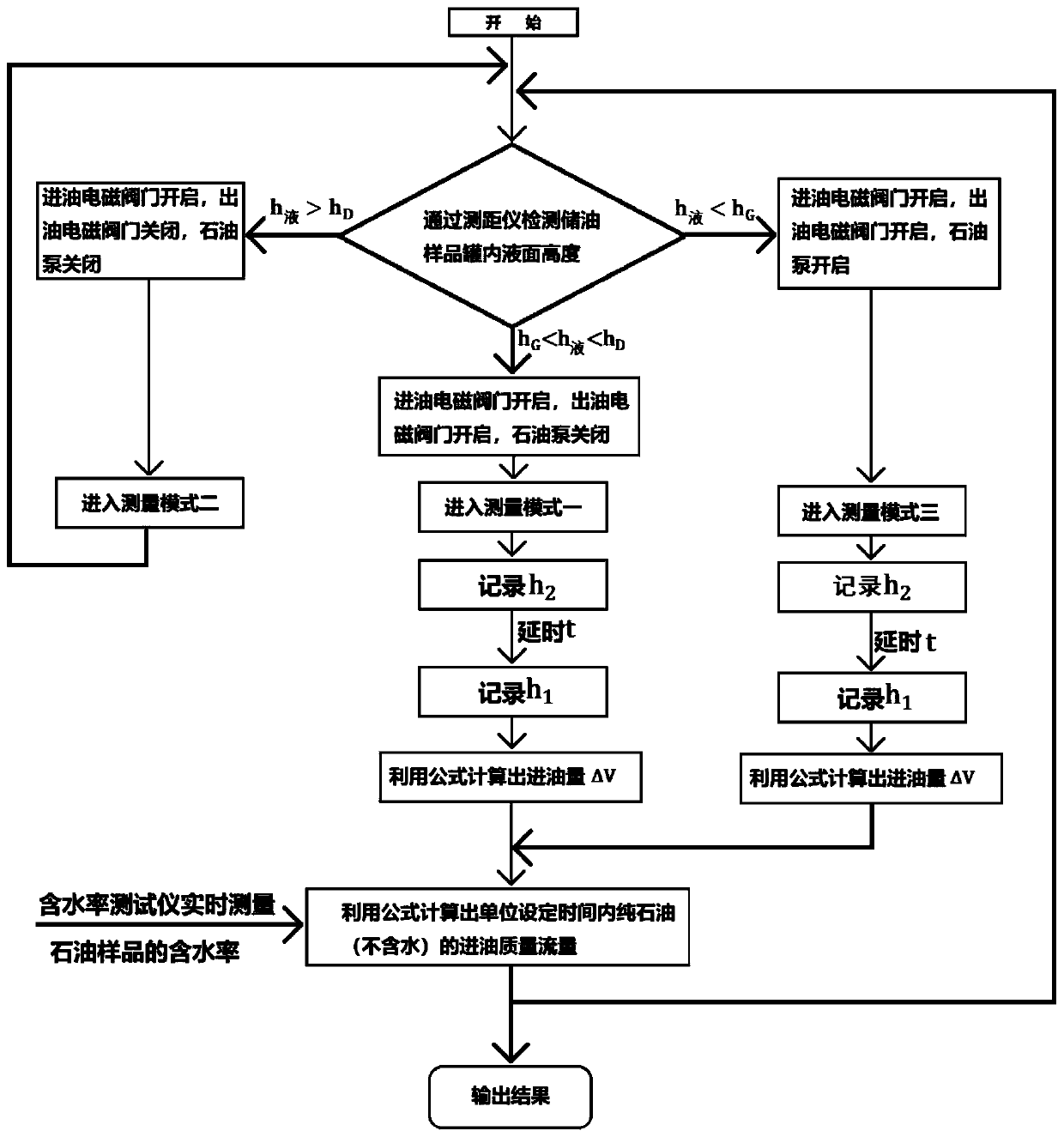

[0021] Such as figure 1 As shown, the oil mass flow detection system of the present invention includes an oil inlet electromagnetic valve 2, an oil outlet electromagnetic valve 3, a petroleum pump 4, a water content tester 5, a range finder 6, and a control system 7; the oil inlet electromagnetic valve 2 is installed on the oil inlet pipe at the top of the oil storage sample tank 1, and the oil outlet electromagnetic valve 3, the oil pump 4 and the water content tester 5 are installed on the oil outlet pipe at the bottom of the oil storage sample tank 1; The top of the oil sample tank 1; the signal output terminals of the rangefinder 6 and the water content tester 5 are connected to the data input terminal of the control system 7, and the three control signal output terminals of the control system 7 are respectively connected to the oil inlet solenoid valve 2 and the oil outlet valve. The control end of the electromagnetic valve 3 and the oil pump 4.

[0022] The oil inlet so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com